A wire harness is a ready-made bundle of individual cables that transmits signals or working currents. The cables are routed as a cable harness and sheathed, or held together by clamps, cable ties, binding twine, or hoses.

In addition to requirements such as miniaturisation and cost efficiency as well as higher currents, signal rates and frequencies, the application area of wire harness testing is characterised by high diversity with low standardisation.

Despite advancing automation, wire harnesses in industry are mostly manufactured manually and assembled according to their geometric and electrical requirements.

Application-specific solutions are readily available.

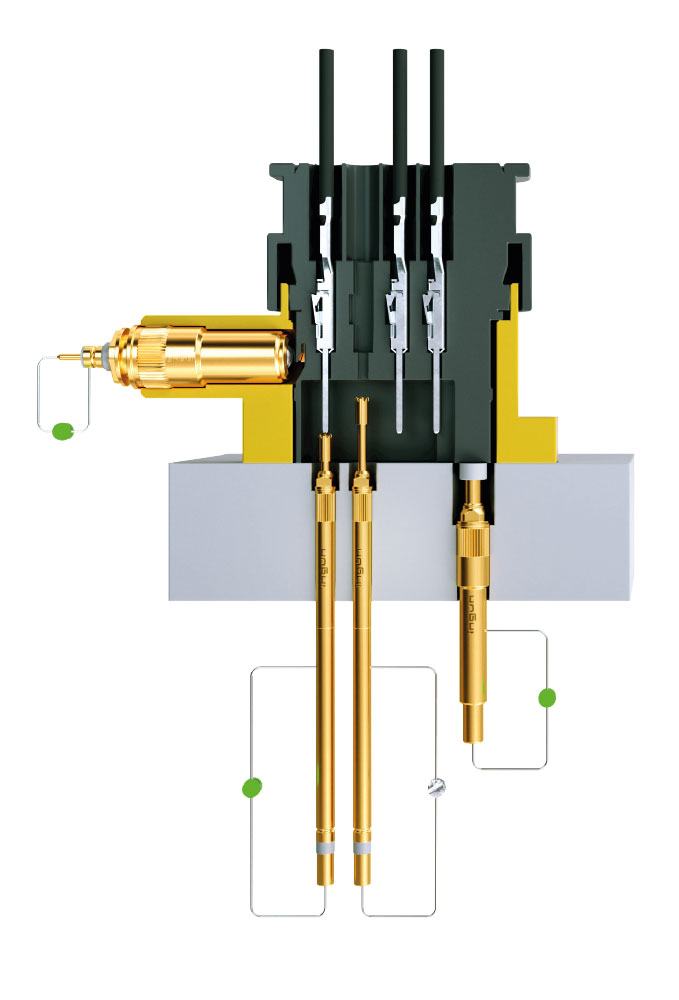

Different types of test probes are used when testing wire harnesses: Screw-in test probes prevent the test probe from migrating out of the receptacle and are therefore preferable for wire harness testing, such as in the continuity test (connection test). Switching probes can be used to detect the presence of plugs and clips, for example, during the detection test. Step probes determine whether the contact terminals are correctly positioned in the connector housings during the position test. In addition, push-back probes are used in the push-back test to check whether the contact terminals remain in the correct position in the connector housing. Finally, non-rotating test probes ensure wear-free contacting of sockets or flat connector blades during connector testing.

Regardless of the wire harness test applications you need to test, INGUN has the right test solution for you.

Go to the desired test solution:

Connection test Detection test Position test Push-back test Connector test

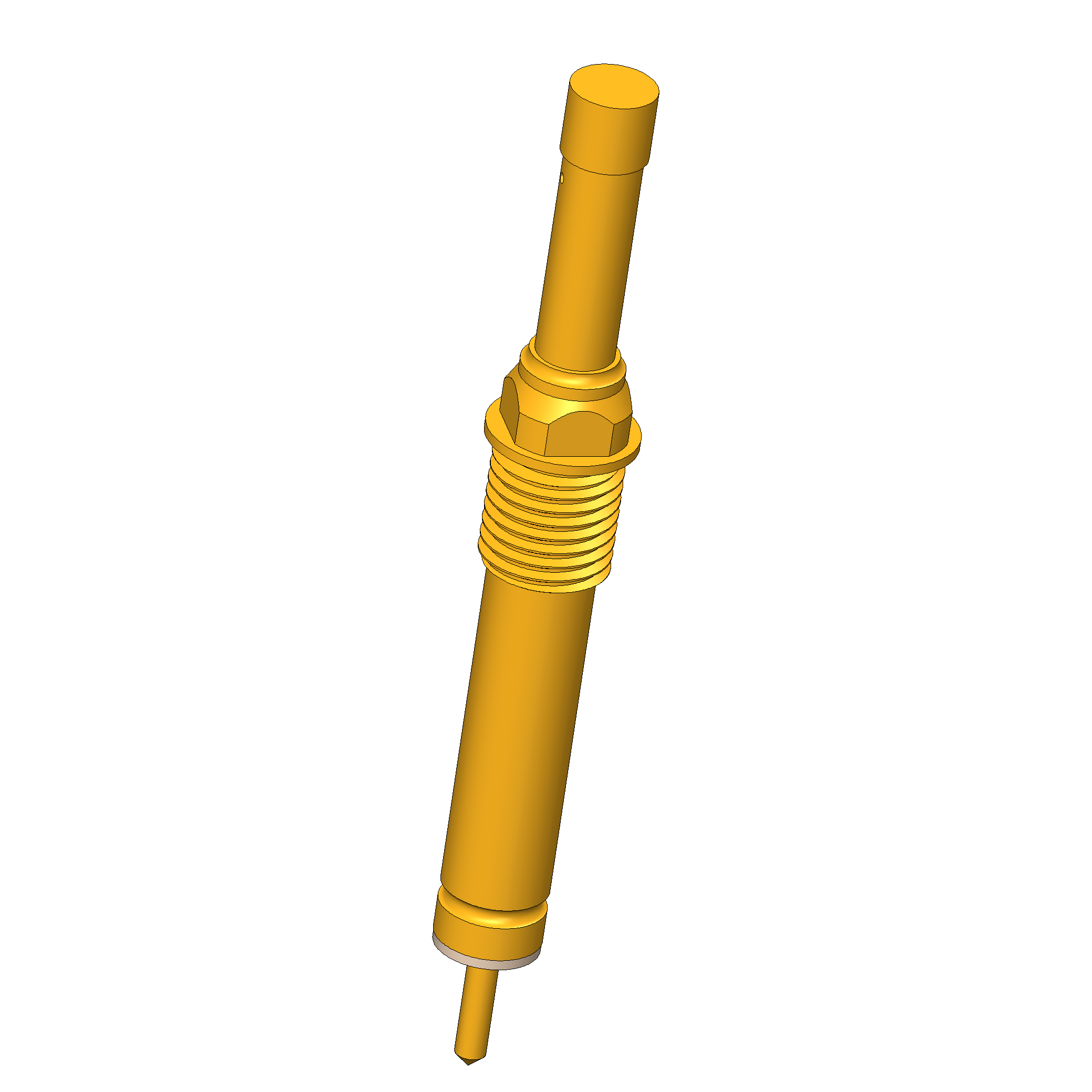

Connection test using screw-in test probes

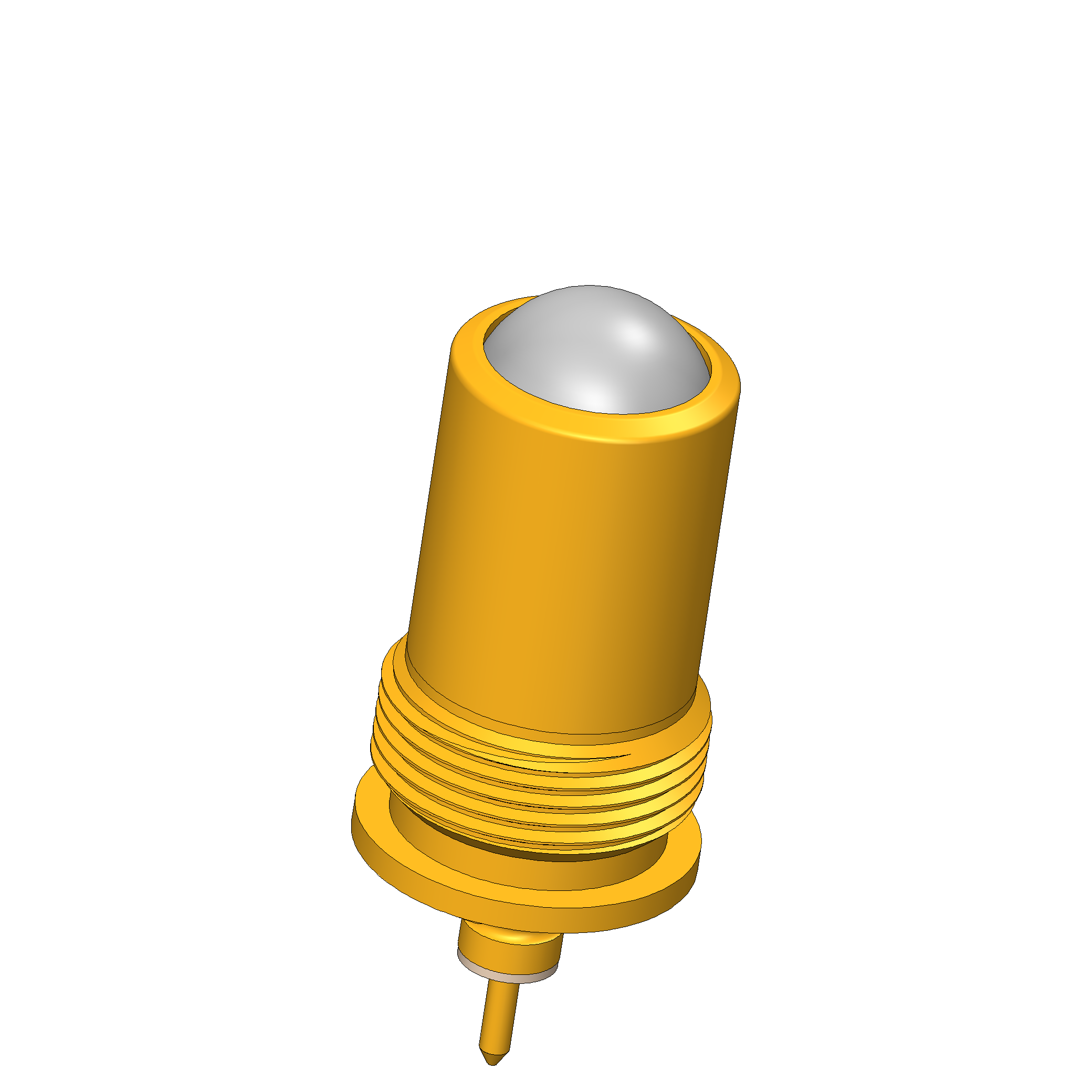

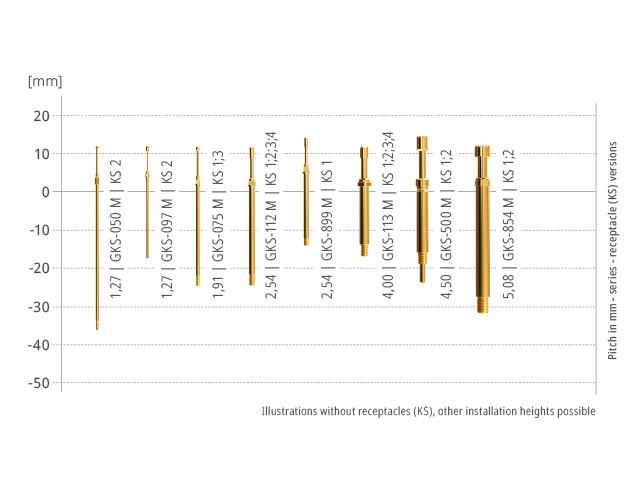

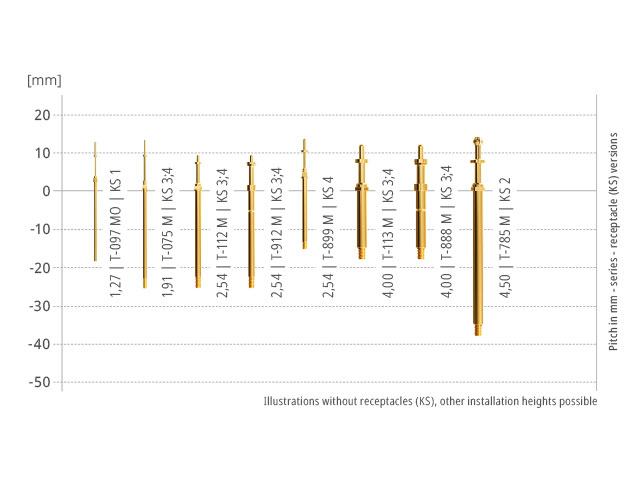

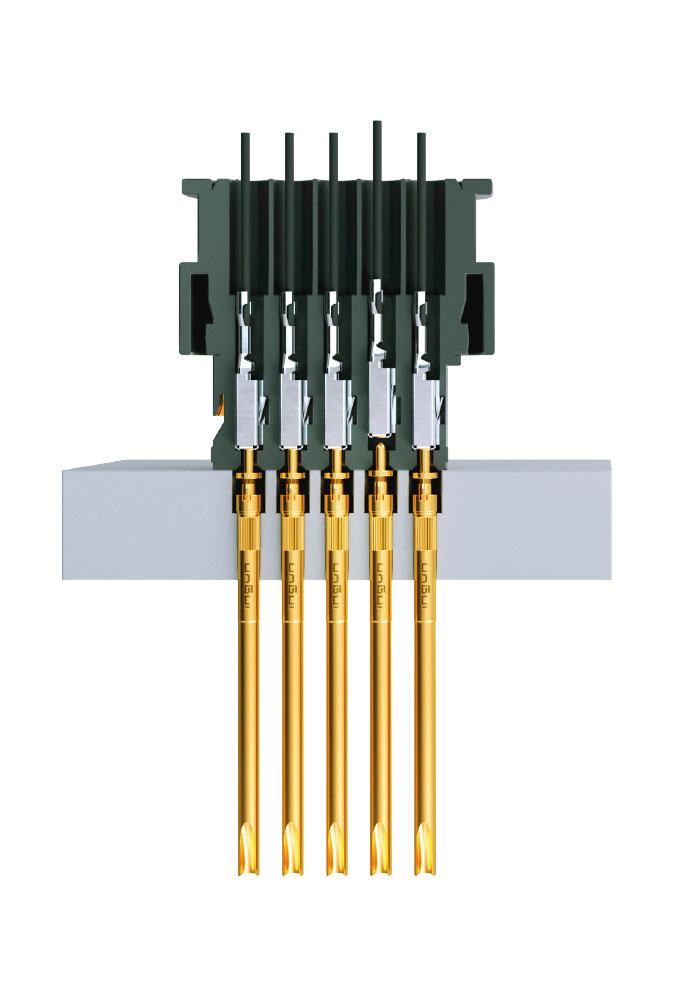

Many of the press-in test probes available from INGUN are also available as screw-in test probes. This ensures the test probe remains securely in the receptacle during the test. Screw-in test probes are especially recommended for applications where vibrations or unwanted side and axial forces may occur. INGUN offers screw-in test probes for the connection test in various sizes.

Go to the desired test solution:

Connection test Detection test Position test Push-back test Connector test

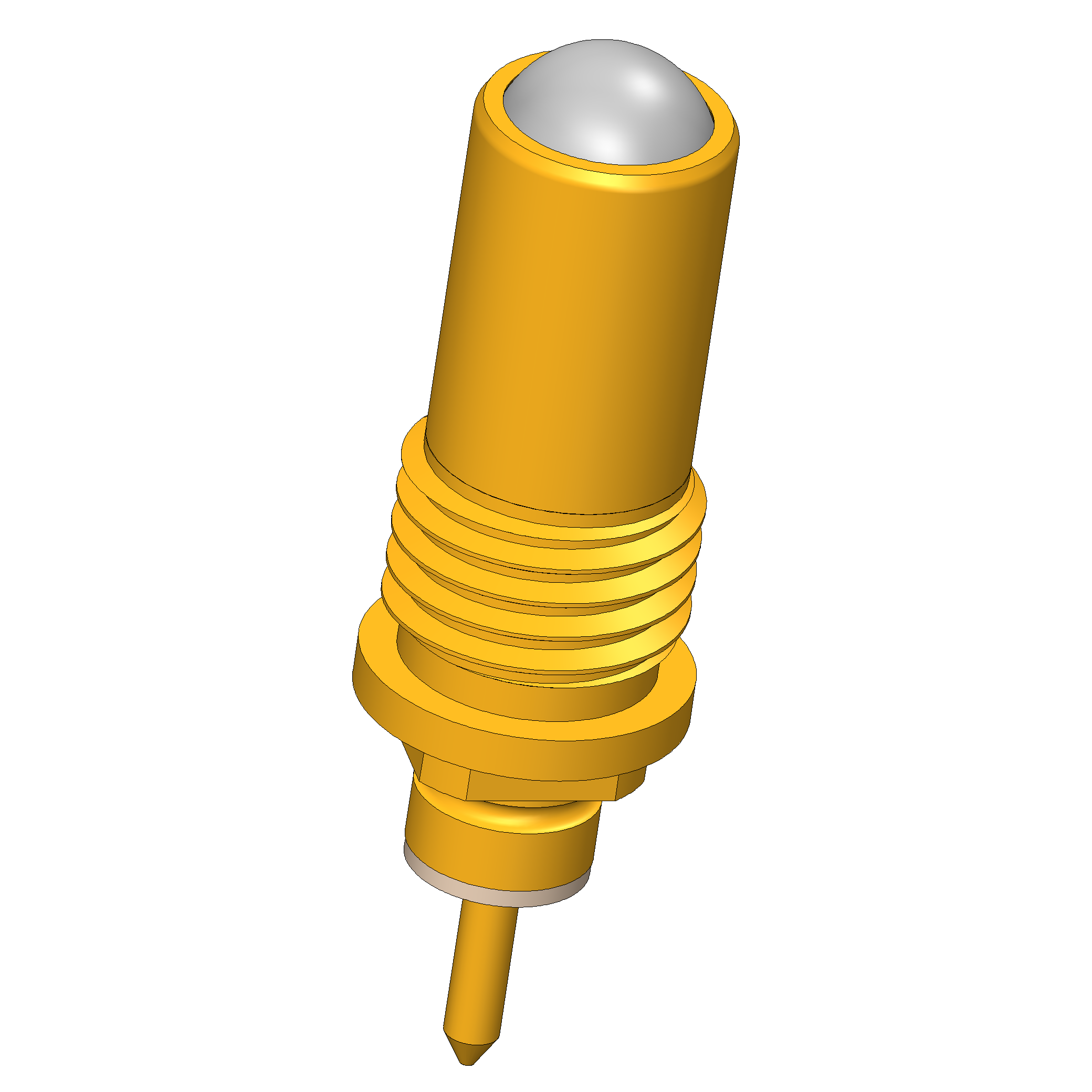

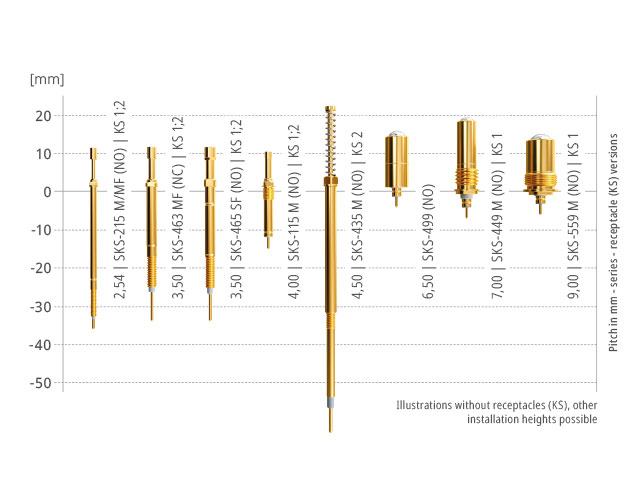

Detection test using switching probes

Switching probes are suitable for many various applications: not only can they be used for component detection tests and switches for closed/open checks, but also as a signal trigger for process control. Furthermore, in combination with other test probes (e.g., push-back probes), the position of contact terminals in plug housings is can be determined. INGUN offers a large variety of different switching test probes in different sizes and in versions as (switching circuit) Normally Open (NO) or Normally Closed (NC), so that a suitable test solution can be found for every application.

Go to the desired test solution:

Connection test Detection test Position test Push-back test Connector test

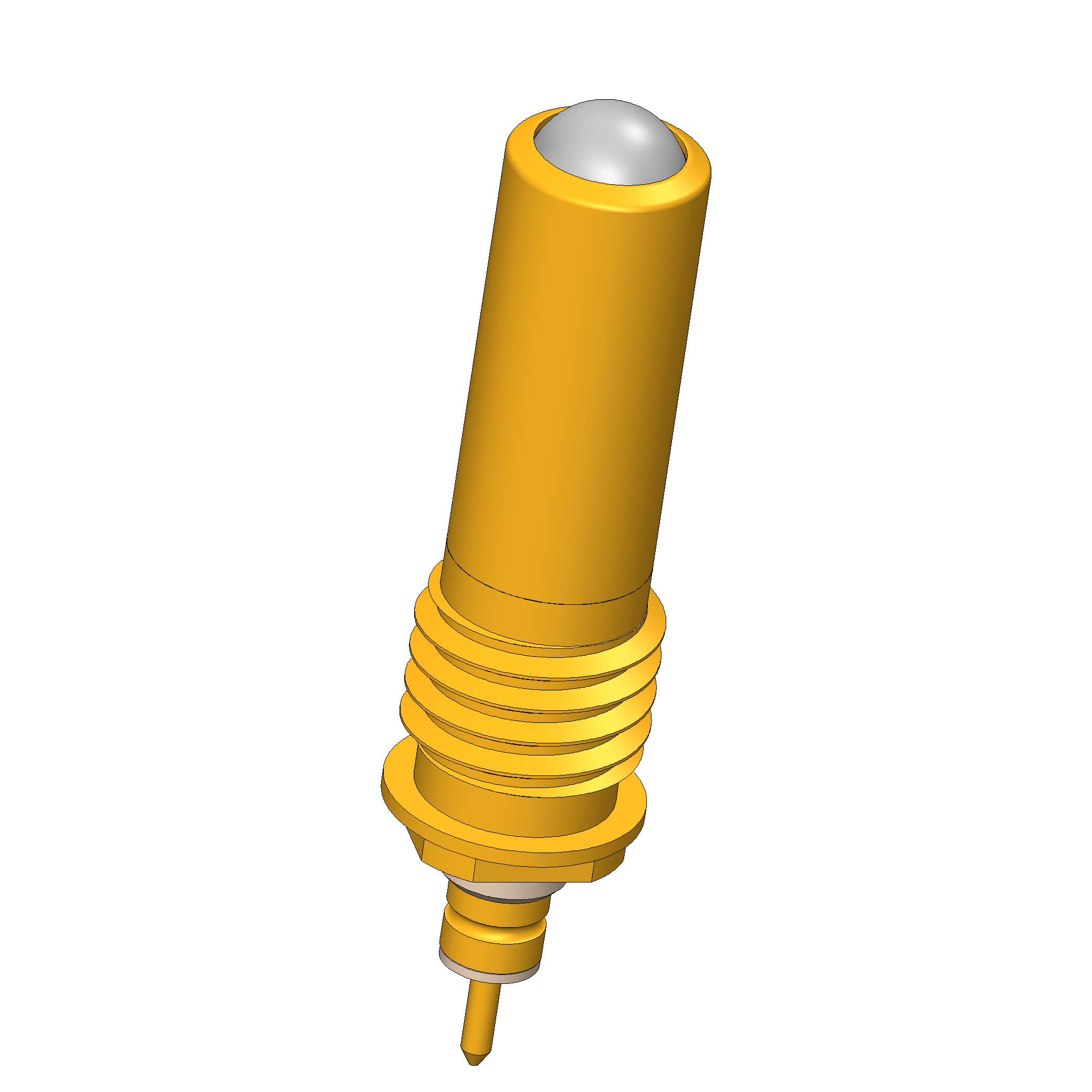

Position test using step probes

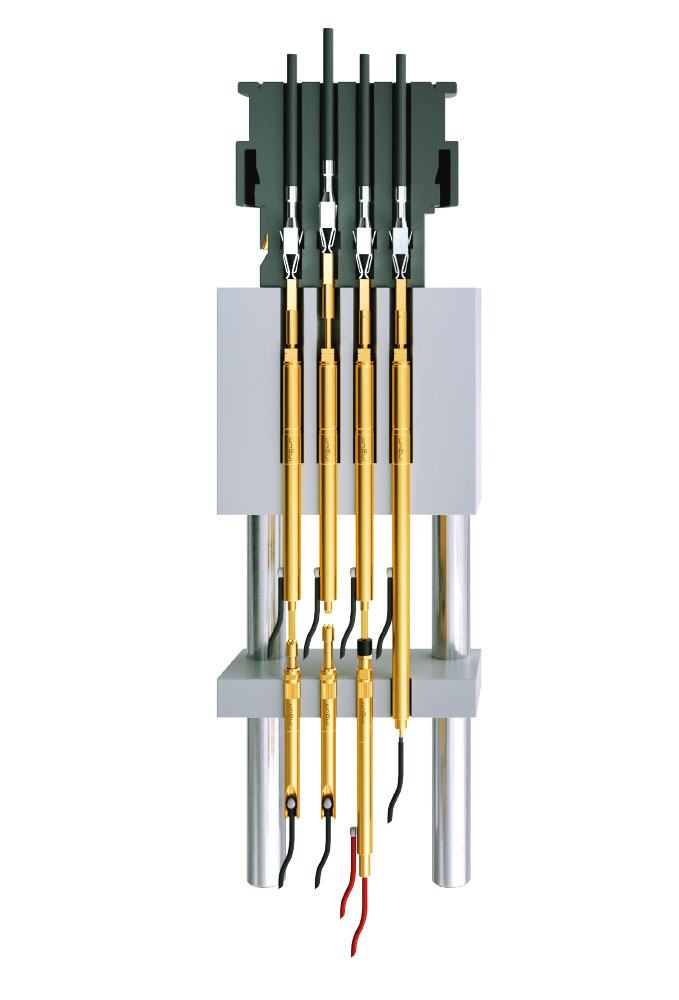

Step probes are used to test the correct position of the contact terminals (contact lamellae) in the plug housings. Contact is only made when the terminals are in the correct position or when the wiring is correct. Step probes differ in terms of their overall length, resulting from the pin length, the pin diameter, and the diameter of the disc.

Go to the desired test solution:

Connection test Detection test Position test Push-back test Connector test

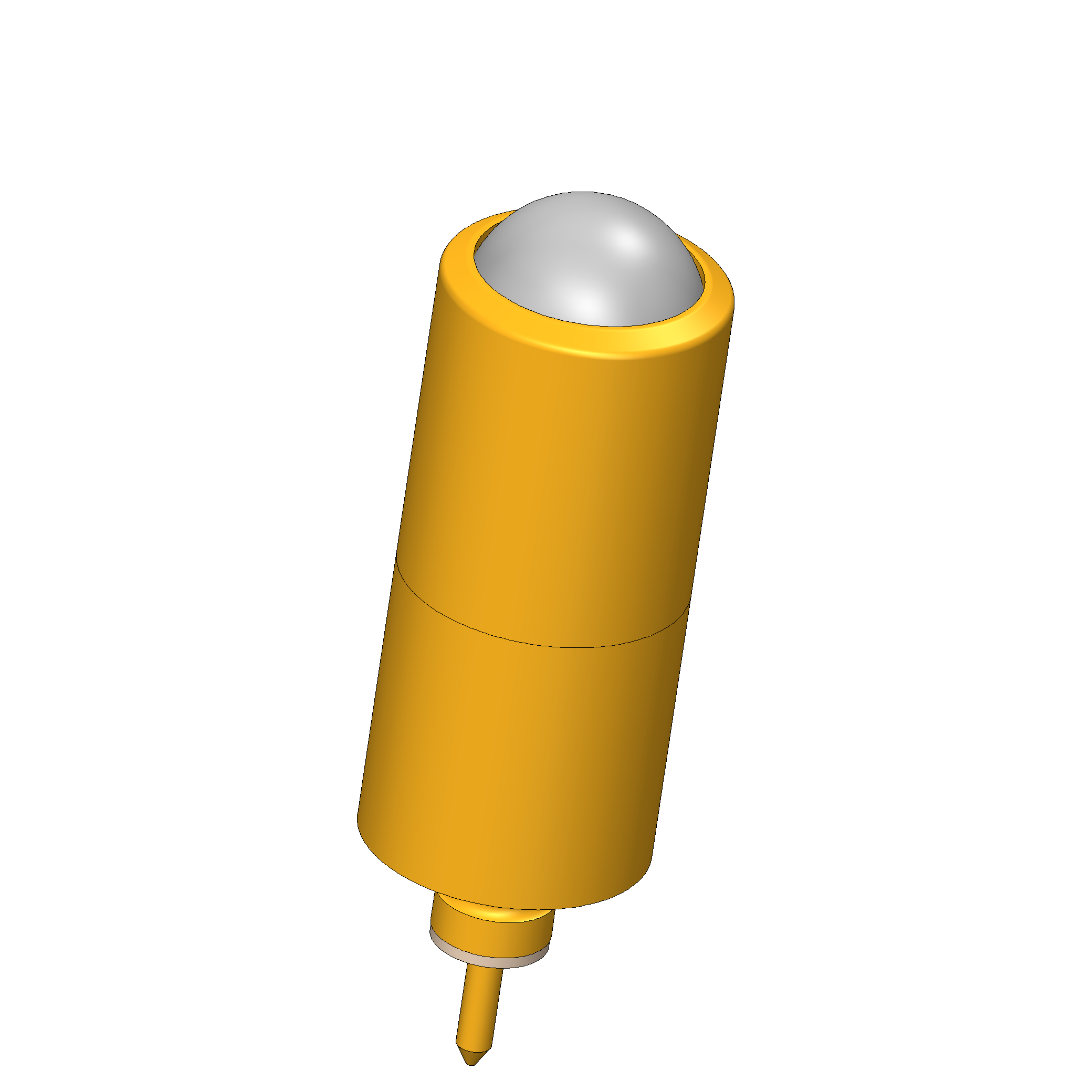

Push-back test using push-back probes

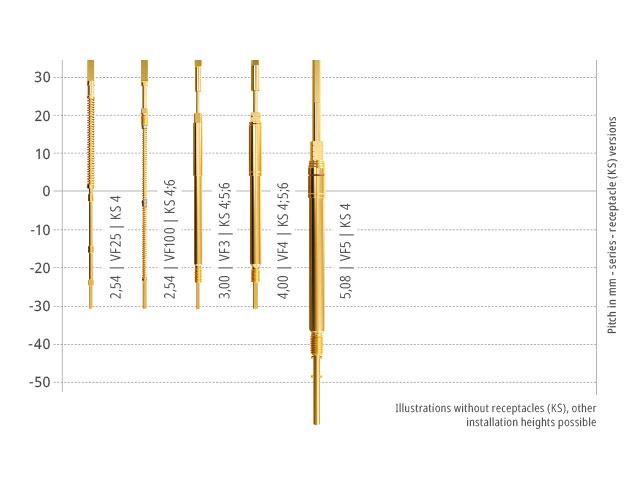

Push-back probes are used to test whether primary and / or secondary latching has occurred to ensure of the contact terminals are in the correct position in the connector housing. Only if the latching is correct, the contact lamellae remain in the correct position and the continuous plunger of the push-back probe presses on a test probe or switching probe installed below. INGUN offers a variety of push-back probes with different dimensions for various grid sizes and with either spade-shaped or round plunger tip.

Go to the desired test solution:

Connection test Detection test Position test Push-back test Connector test

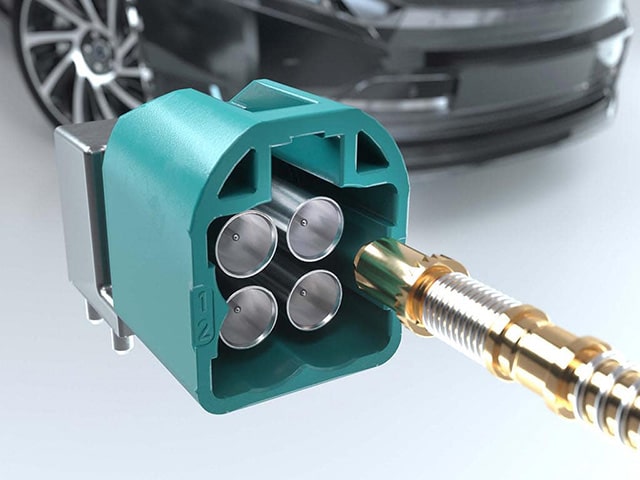

Connector test

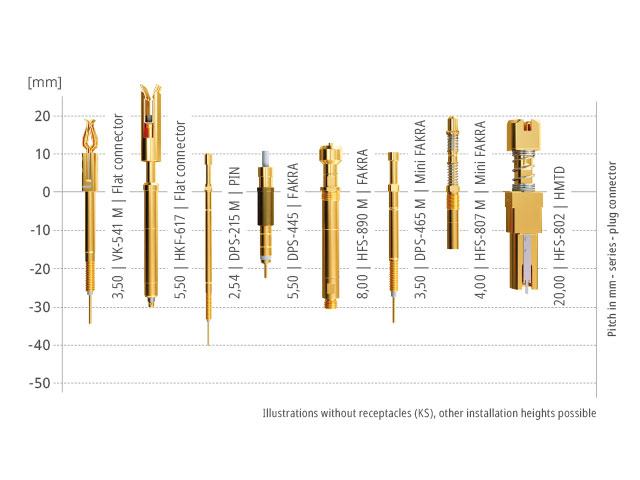

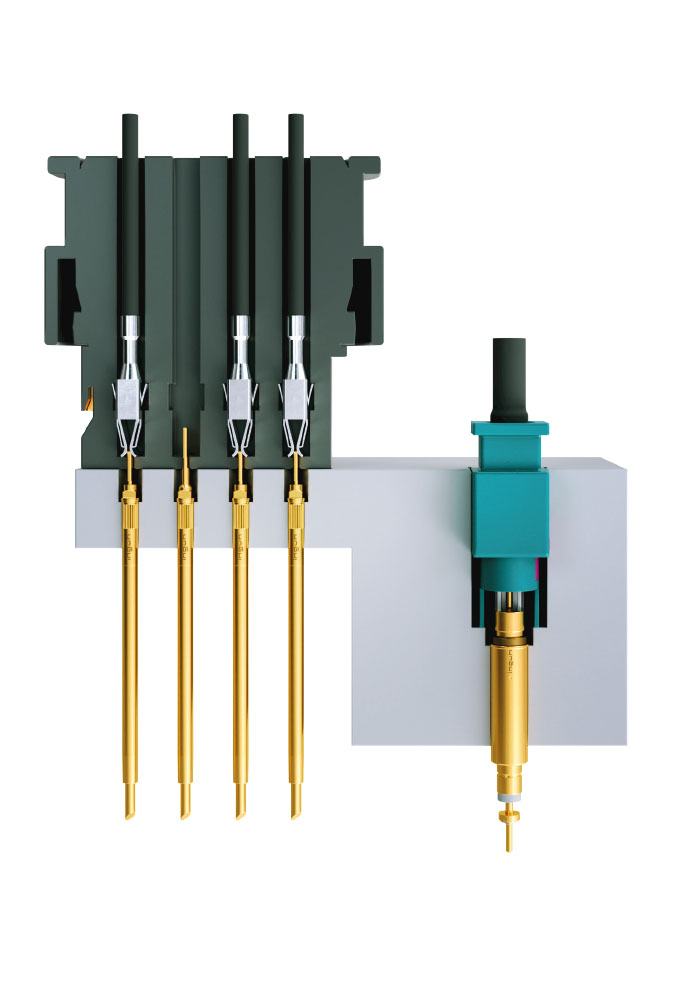

Correctly aligned contacting is required for non-destructive testing of DUTs such as flat connectors or sockets. INGUN non-rotating probes ensure this. For tests on coaxial radio-frequency connectors, either radio-frequency probes (HFS) or dipole probes (DPS) are used for a simple continuity test. The latter is often referred to as four-wire or Kelvin measurement. INGUN offers suitable test solutions for all standardised automotive connectors.

Non-rotating probes

Non-rotating test probes are used for testing DUTSs such as sockets, or connectors with flat blades that need to be contacted at a specified angle of rotation. This is the only way to perform a non-destructive test. These probes are already mounted in the correct position during assembly and are designed to ensure the plunger tip is correctly aligned and rotation is not possible.

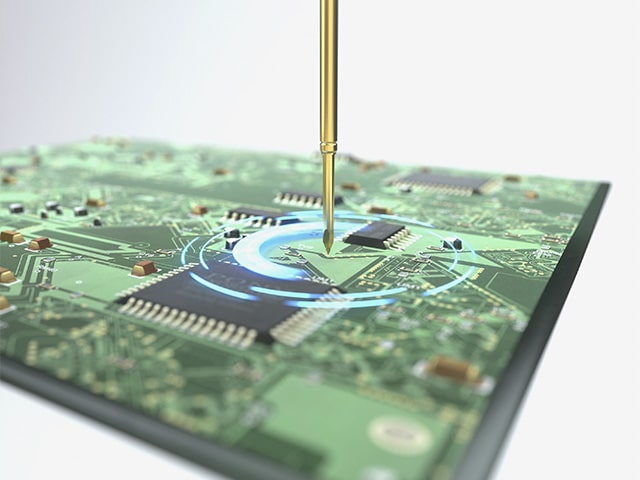

Radio-frequency test probes

For the optimal fulfilment of the test requirements in the radio frequency range, various versions of the RF probes are available. The selection criteria are the test point to be contacted, the frequency or data rate, the installation area, and the ambient conditions.

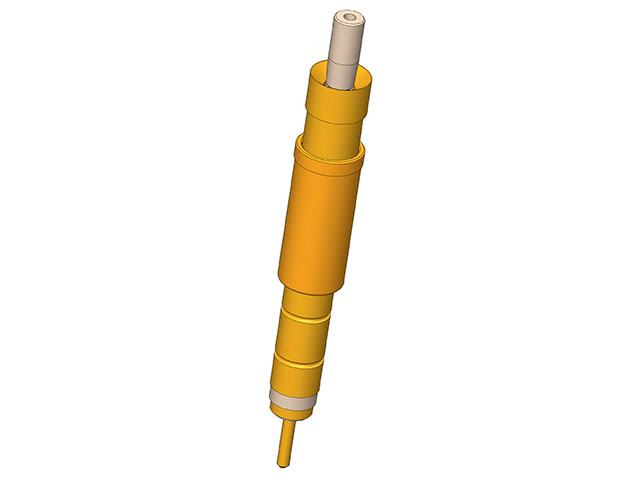

Dipole probes

The dipole test probes developed by INGUN are ideal for performing 4-wire measurements thanks to their coaxial design. This allows the voltage and current to be measured directly on the contact surface and the resistance to be determined. Furthermore, it is also possible to perform connection tests on coaxial plug connectors. Depending on the application, probes with various plunger tips and dimensions are available for various grid sizes. The dipole probes are mounted in a receptacle. Connection is achieved either by using a connector or by a solder connection to the receptacle.

Go to the desired test solution:

Connection test Detection test Position test Push-back test Connector test

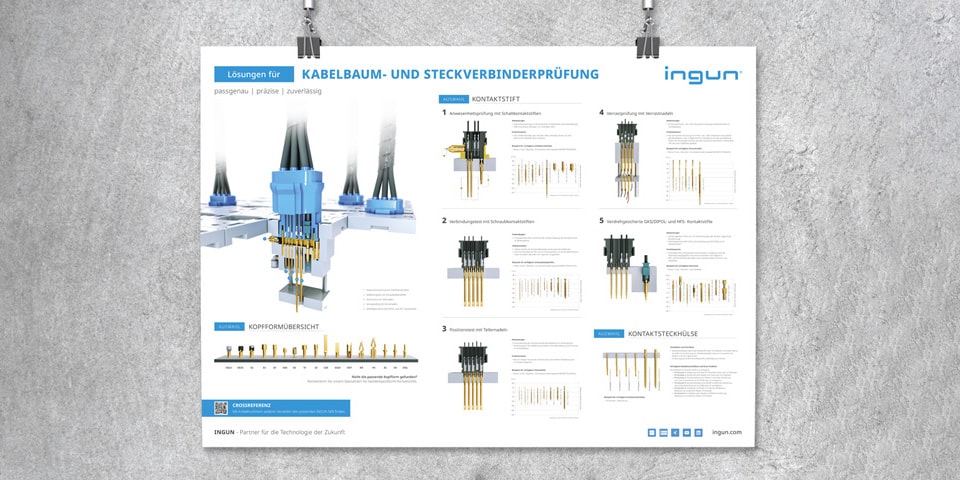

Test probes for wire harness applications at a glance

With the INGUN poster featuring probes for wire harness contacting, you will find all options to create the optimum solution for your configuration presented simply and clearly.