PRODUCTS

„INGUN ensures the optimal connection between test point and test system through the world's largest portfolio of test fixture kits, customising accessories, and test probes.“

As a Partner for Future Technology, you can rely on our product and solution competence: After intensive analysis of common test systems, we have used the latest methods to further develop the signal quality of the interface test probes to the highest level, enabling reliable and more precise measurements. The new MintPin significantly reduces pseudo errors as well as error messages at the interface, therefore sustainably increasing efficiency in production.

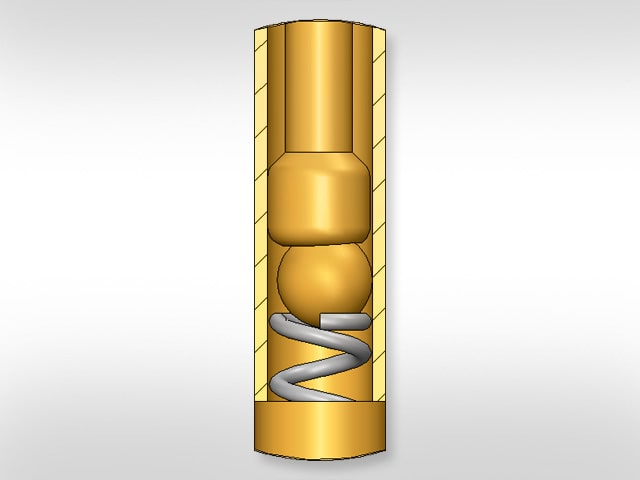

1. Improved transmission resistances

A gold-plated ball between the plunger and the spring ensures lower, stable contact resistance. In addition, the off-set centring in the plunger ensures constant deflection, leading to significantly improved internal resistance.

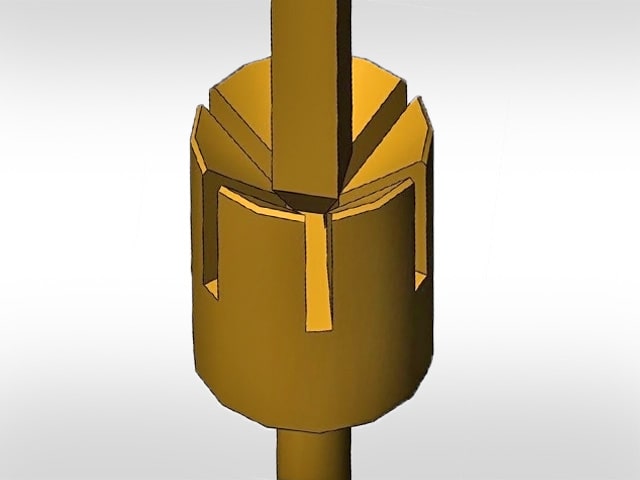

2. Optimised contact

surfaces

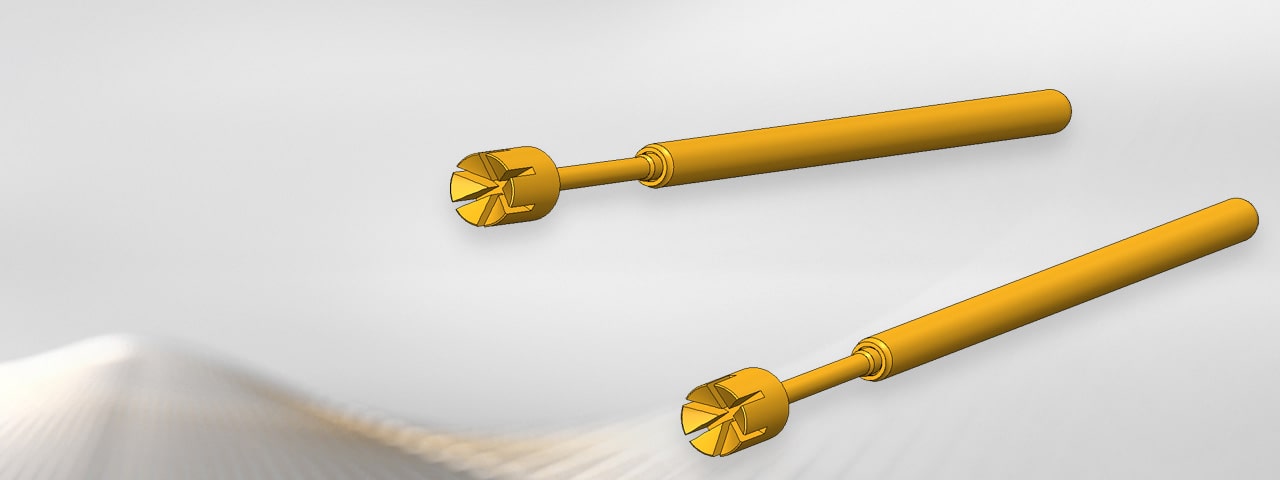

Due to the geometry of the plunger tip (self-cleaning inverse cone with cleaning slots), the MintPin offers the maximum contact surface in comparison to the existing interface contact probe (serrated tip, 06).

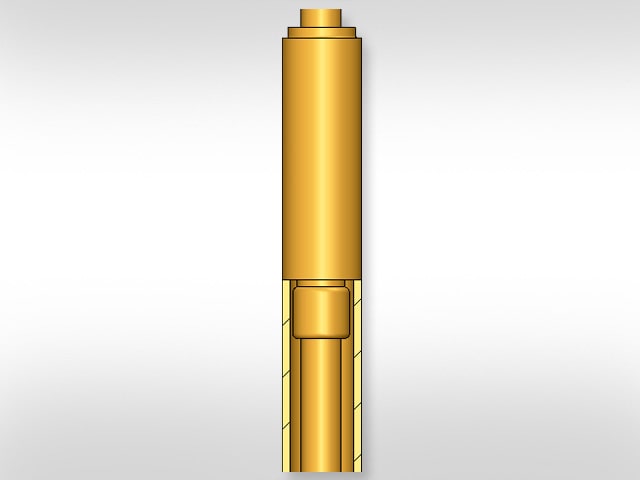

3. Increased

durability

The newly developed interface test probe aligns itself optimally with the personality pin in the test fixture interface thanks to the plunger, which is designed to wobble (±0.2mm). Side forces are compensated, making the new MintPin extremely durable.

Previous interface test probes typical Ri: < 20 mΩ

Newly developed interface test probes (MintPin) typical Ri: < 3 mΩ

The newly developed interface test probes can be installed directly in the interface in the Keysight i3070 to replace existing interface test probes and are available with 1.0N and 2.0N spring force.

They are currently available for Keysight and SPEA test systems.

Keysight i3070:

| Part number | Description |

| GKS-100-1850 | GKS-100 319 230 A 2000 Q15 |

| GKS-100-1960 | GKS-100 319 230 E 2000 Q15 |

| GKS-100-1936 | GKS-100 319 230 A 1000 Q15 |

| GKS-100-1994 | GKS- 100 319 300 A 1000 Q15 |

SPEA:

| Part number | Description |

| GKS-100-1998 | GKS-100 319 180 A 1000 Q |