Designed for the most challenging test conditions

INGUN has designed a new test probe series specifically for challenging contacting of tough OSP coatings, lead-free soldering, or contaminated printed circuit boards (PCBs). Despite harsh conditions, these probes achieve outstanding test results, and boast the following features:

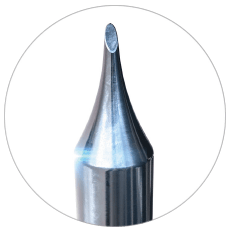

- Aggressive tip styles

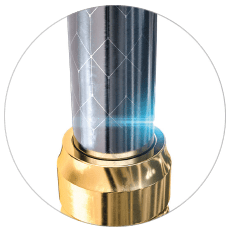

- Robust plating

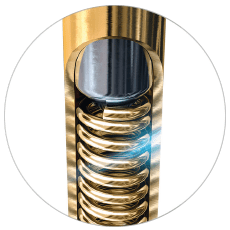

- Increased spring pre-load

Suitable Solutions

For varied test requirements

Infinite benefits

Saving time and costs in the testing process

- Increase of the first pass yield thanks to the optimal combination of the tip style geometry, the plating, and the contact dynamics

- Optimal utilisation of the product capacity thanks to reduction of test cycles needed

- Long lifespan thanks to the extremely hard-wearing plating

- Reliable test results thanks to improved electrical contact

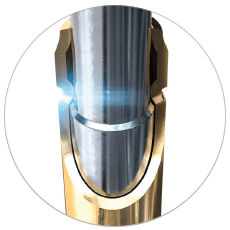

- Fewer damaged PCBs due to as little impact as possible from the spring forces resulting in low-stress contacting

- Effective self-cleaning effect of the plating results in fewer process interruptions caused by contamination and residues

- Can be used for a wide range of applications

INGUN E-TYPE® FUSION

The high-performance solution for the most demanding test requirements

Increased First Pass Yield

For reliable contacting

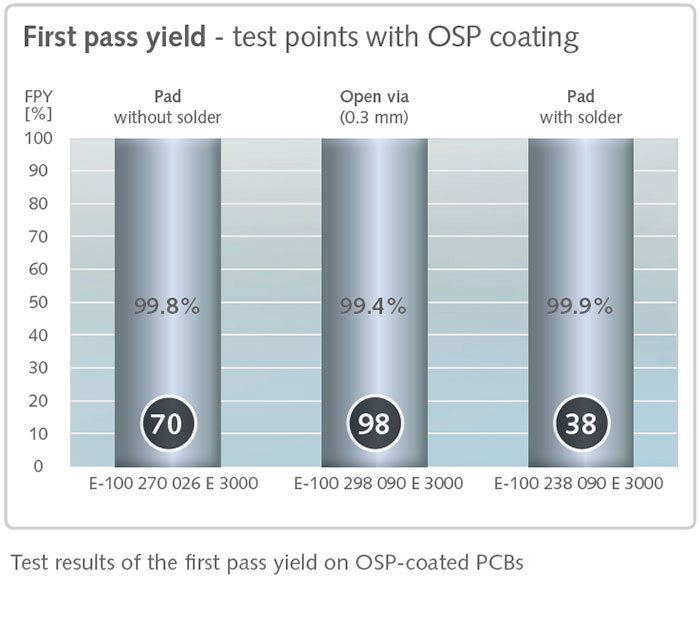

When contacting test points, first of all it is important to achieve reliable contact. Furthermore, consistent resistance, kept as low as possible, is required to perform measurements which are both precise and repeatable. The following chart shows results from measurements performed on OSP-coated PCBs. The measurements were conducted up to 50,000 test cycles in the INGUN testing laboratory. During the test, the behaviour of tips style 70 on pads without solder, tip style 98 on open vias, as well as tip style 38 on pads with solder was examined.

The image shows the tip styles selected for the test all achieved reliable contact with the test point. The first pass yield, contact achieved during the first test cycle, is over 99 % in each case. This leads to significant cost and time savings in the test field.

Specialised Plating

For the best edge-retention properties

The palladium-nickel plating, which was specifically developed for the test probes in the INGUN E-TYPE® FUSION series, are characterised by a surface hardness value three times higher than standard gold plating. With these characteristics solid layers of contamination and top layers, such as OSP can be penetrated without the tip style losing its edge-retention properties, and ultimately its aggressiveness. Another positive effect of the plating is that it repels contamination, which reinforces the self-cleaning effect of each tip style – for unimpaired contact.

Increased Contact force

For reliable penetration of the test surface

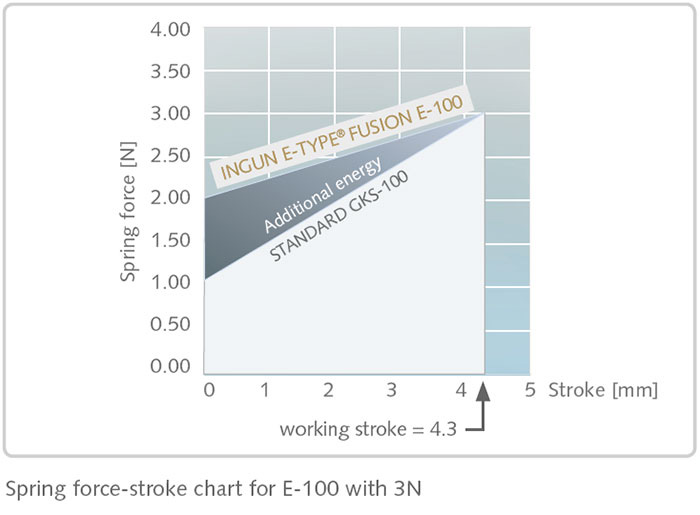

The INGUN E-TYPE® FUSION test probes based on the established INGUN E-TYPE® technology and enables the highest contact reliability on the PCB without subjecting it to excessive stress. This provides a 100 % higher contact force when impacting the test surface, which is achieved by the increased spring pre-load. The FUSION test probes, however, have the same spring force at working stroke as a standard test probe (GKS). The additional contact force initially gained ensures reliable penetration of insulated top layers and a contact surface between probe and PCB which is up to 25 % larger due to the penetration depth.