Receptacle KS-075 30 G Item KS-07530G

Receptacle KS-075 30 G Item KS-07530G

Please log in to show the price

Login

The prices listed in the scale are displayed rounded, therefore deviation in the total price is possible.

Shipping costs

* The prices are rounded to two decimal places.

Technical data

| Product group : | Receptacles (KS) |

|---|---|

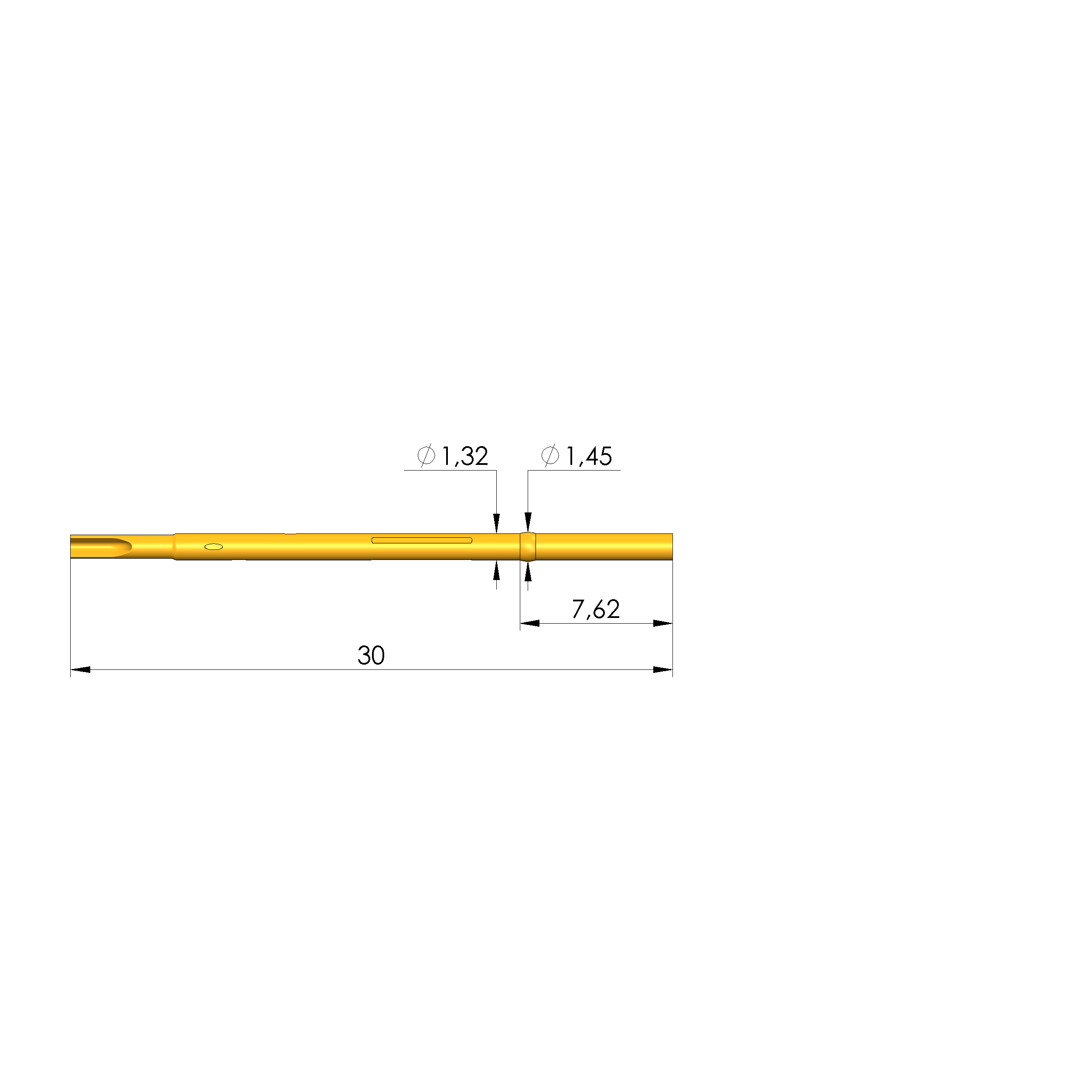

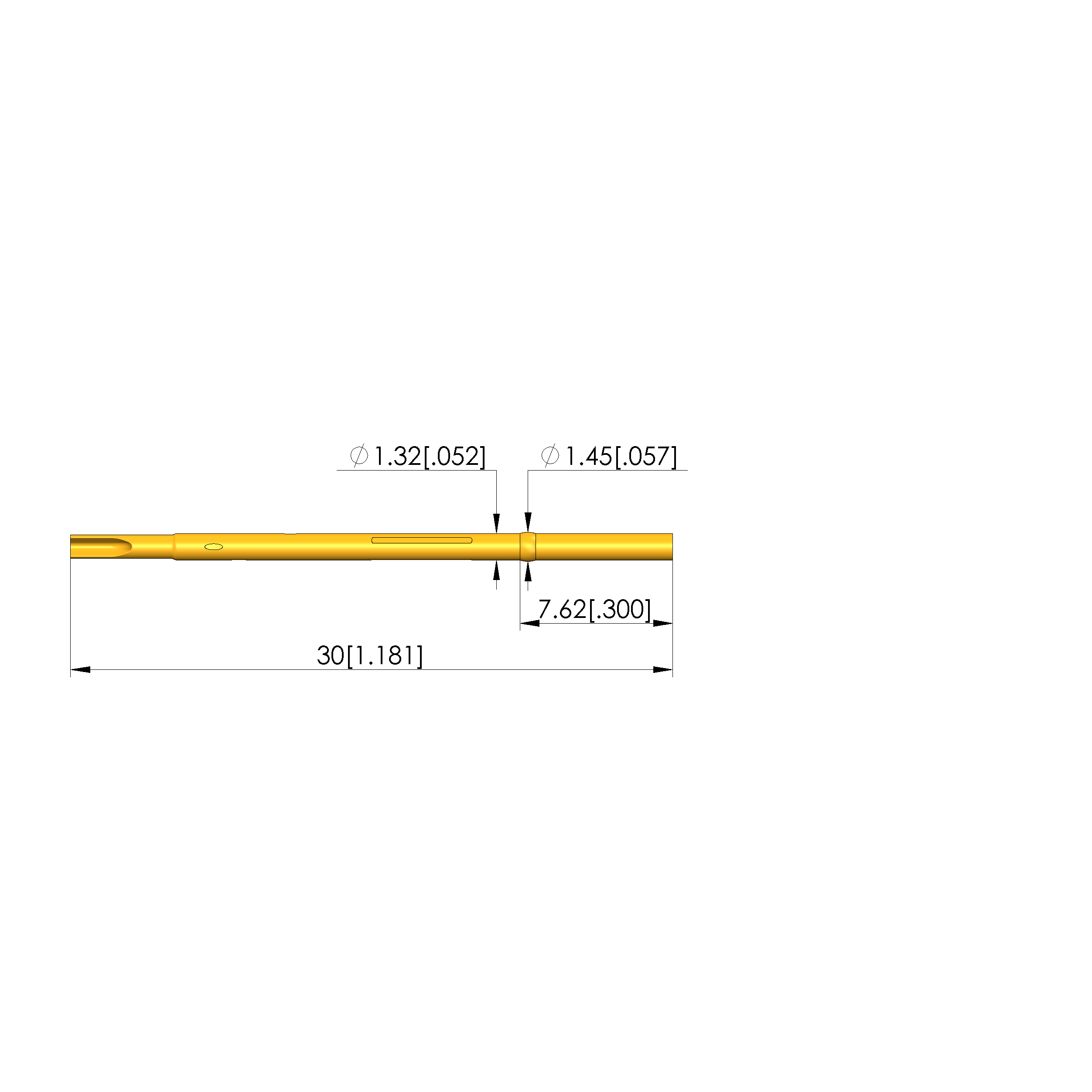

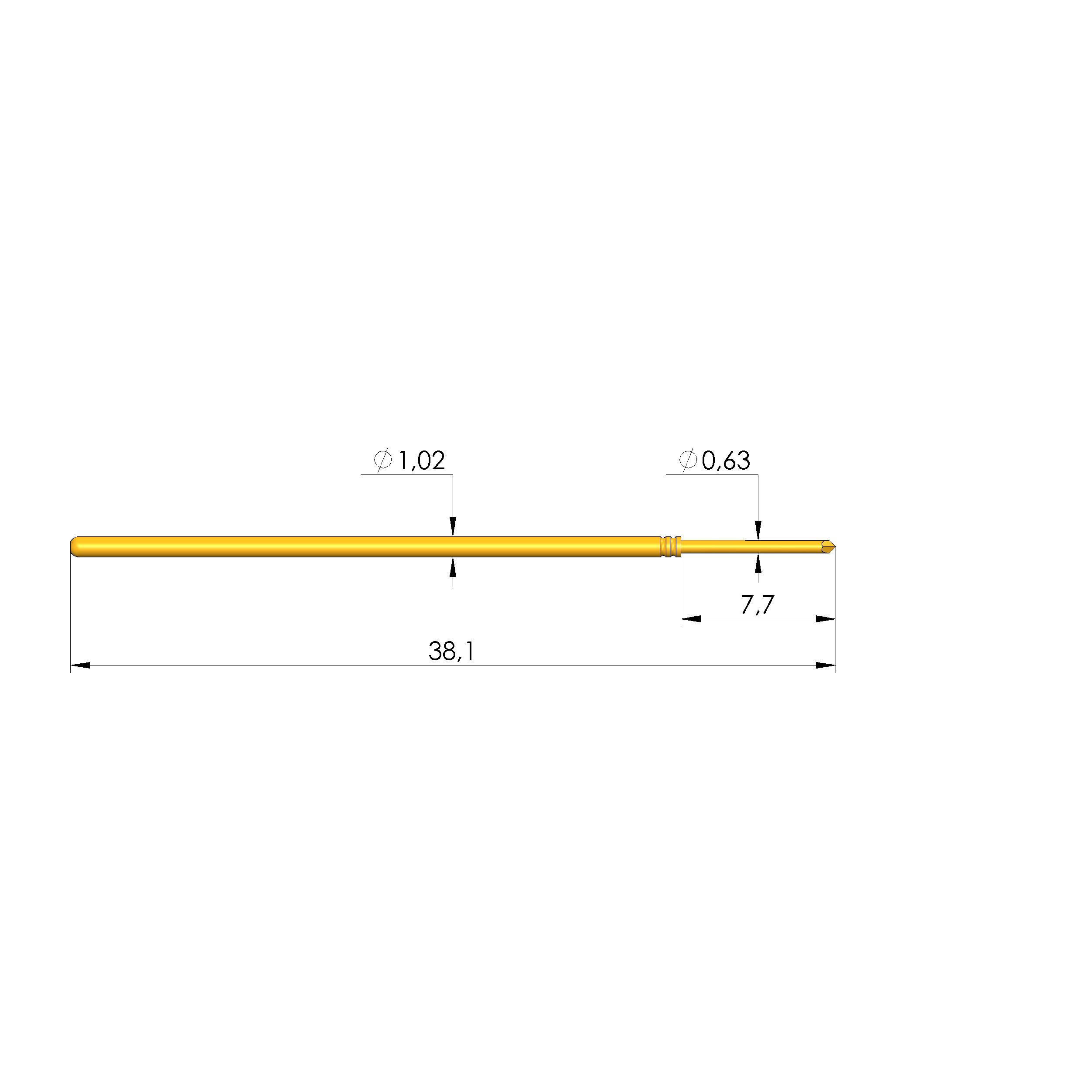

| Series : | KS-075 |

| Sub-series : | KS-075 press-in version |

| Type of receptacle connection : | Solder |

| Press ring : | Yes |

| Surface area : | Gold |

| Collar diameter : | 1.47 mm |

| Collar height : | 7.6 mm |

| Knurl : | No |

| Vacuum-tight : | No |

| RoHS-compliant : | RoHS-3 |

| Mounting hole in CEM1 : | 1.30 - 1.32 mm |

|---|---|

| Mounting hole in FR4 : | 1.31 - 1.33 mm |

| Mounting hole with press ring in CEM1 : | 1.39 - 1.40 mm |

| Mounting hole with press ring in FR4 : | 1.39 - 1.40 mm |

| Total length : | 30 mm |

|---|---|

| Outer diameter : | 1.32 mm |