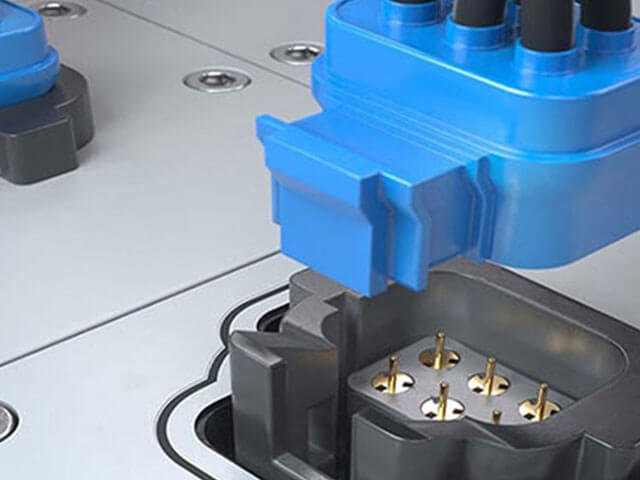

Connectors are an indispensable element in the modern electrified and networked world. They enable the modular structuring of assemblies and devices, systems, or plants. They additionally connect decentralised peripheries or sub-systems for power transmission and data/signal communication.

The multitude of possible applications has led to a very large variety of connectors. This is caused, among other things, different standards regarding design, application area, and electrical signals. Standardised applications include analogue, digital, or radio frequency signal communications as well as power transmission for high current or high voltage requirements.

The INGUN product portfolio is focused on these connectors installed in the intended application and is essential for robust, high-quality, reliable use in the test environment in the laboratory, as well as under simulated of actual conditions.

Connector solutions

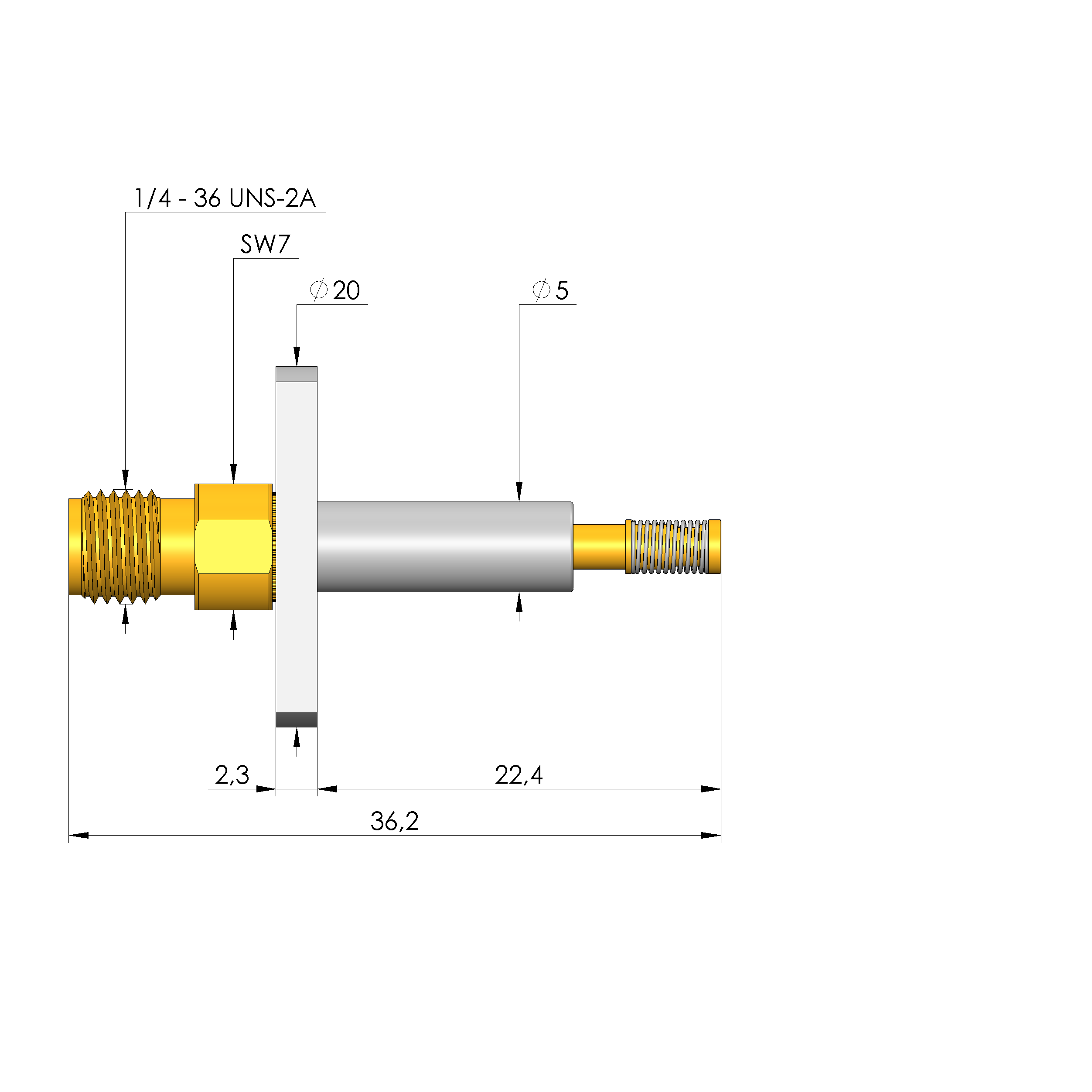

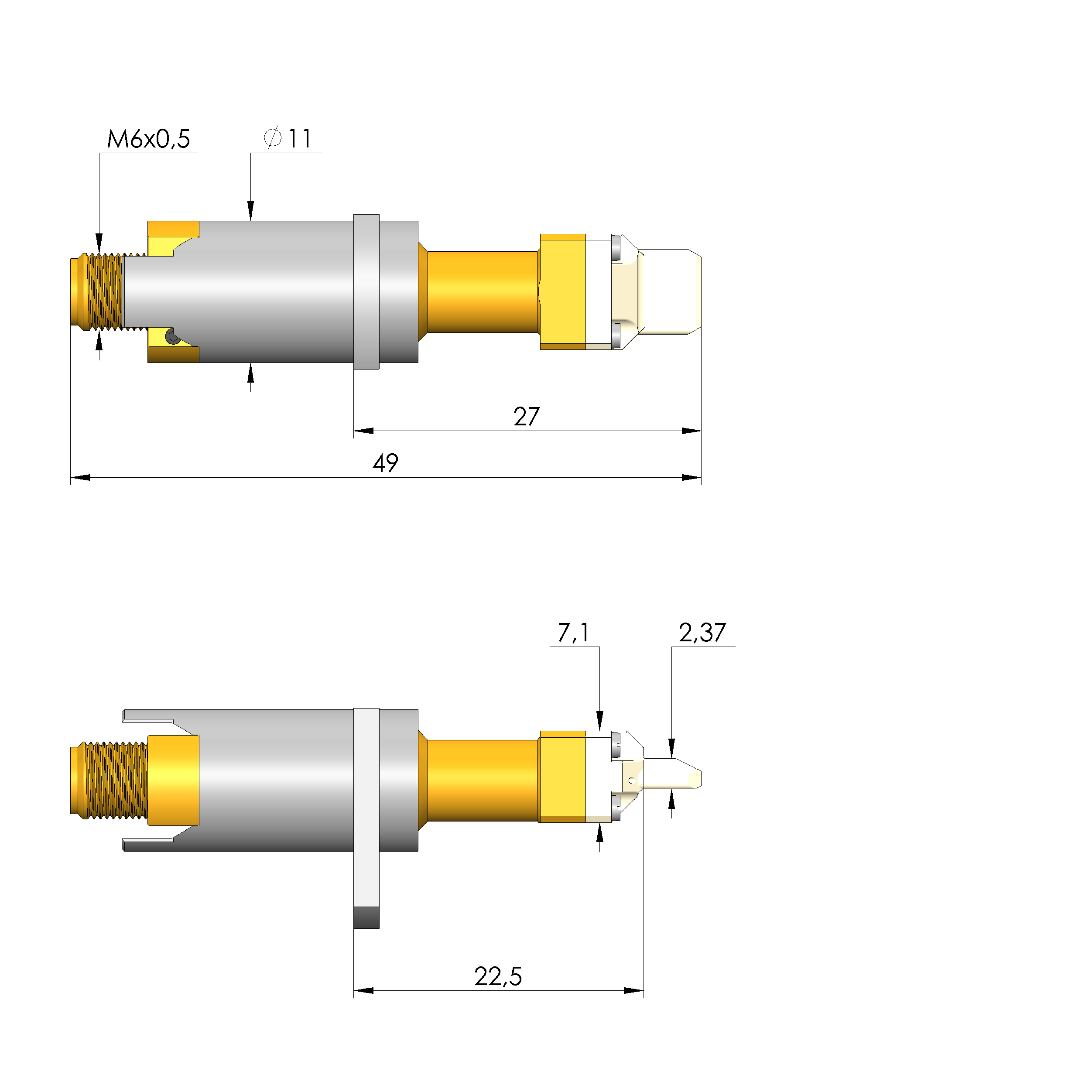

Radio frequency

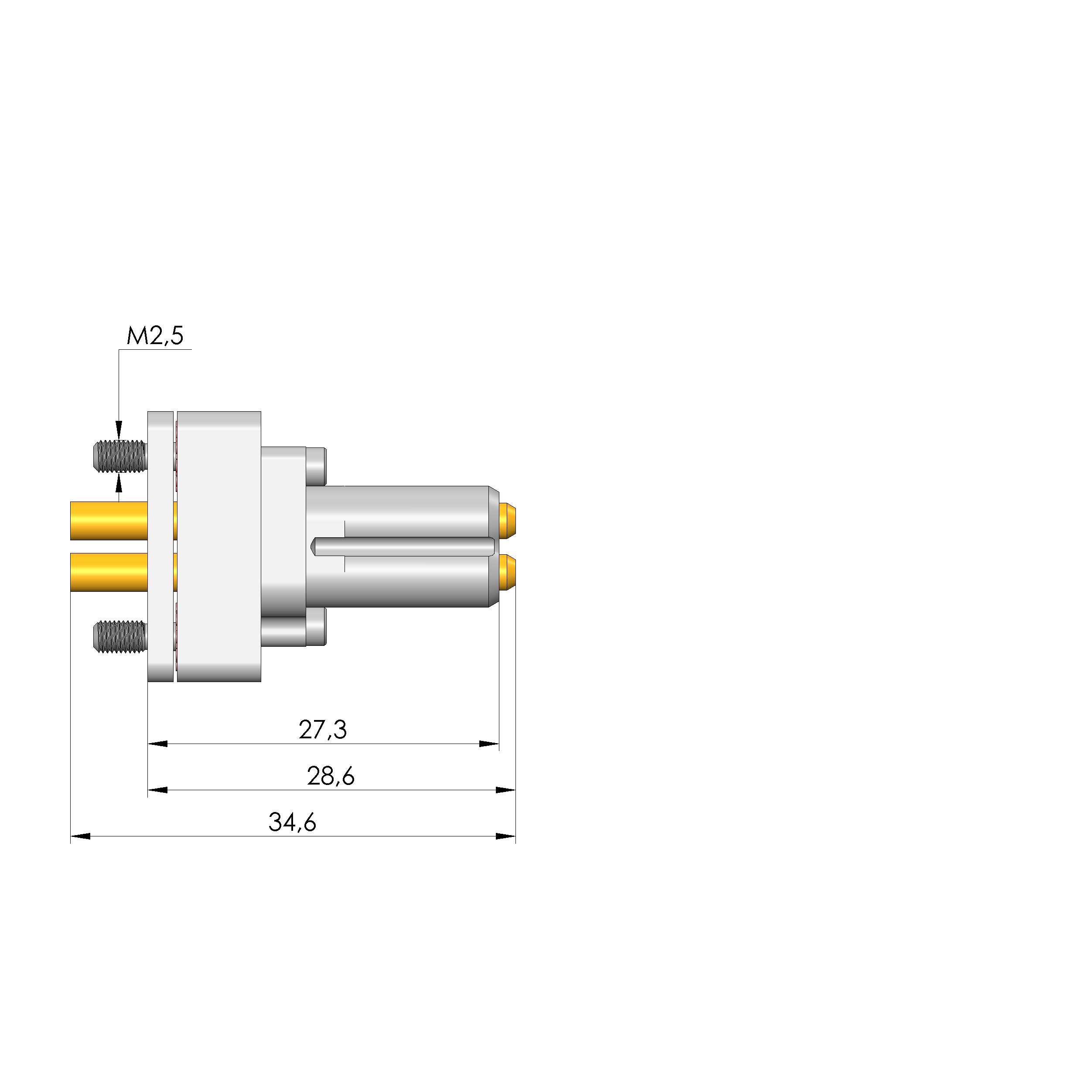

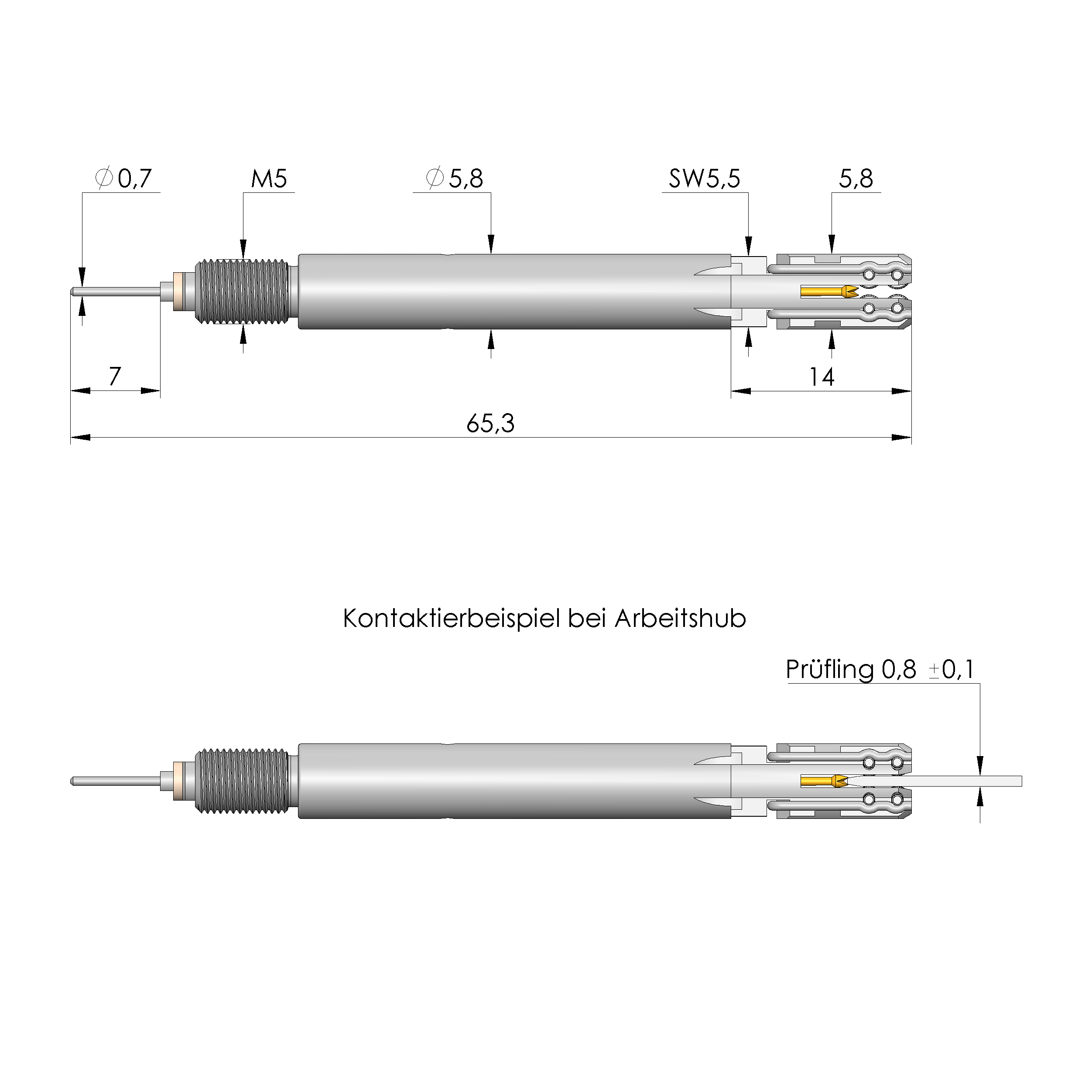

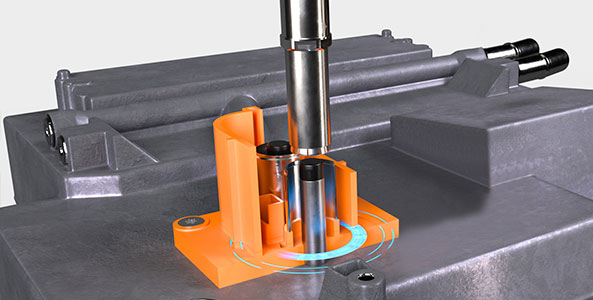

Using INGUN's radio frequency test solutions, precise, self-centring contacting of connectors is possible. Our customers can choose from a wide range of standardised test probes for the automotive sector such as FAKRA, mini-FAKRA, HSD, H-MTD, Mate-AX, Mate-Net or MX series. For data transmission, a basic distinction is made between two systems: coaxial connectors, which tend to be used for analogue signals, and differential connectors, which are used for digital signals. In the test plug product range, efficient contacting for connectors such as USB, RJ or HDMI are available.

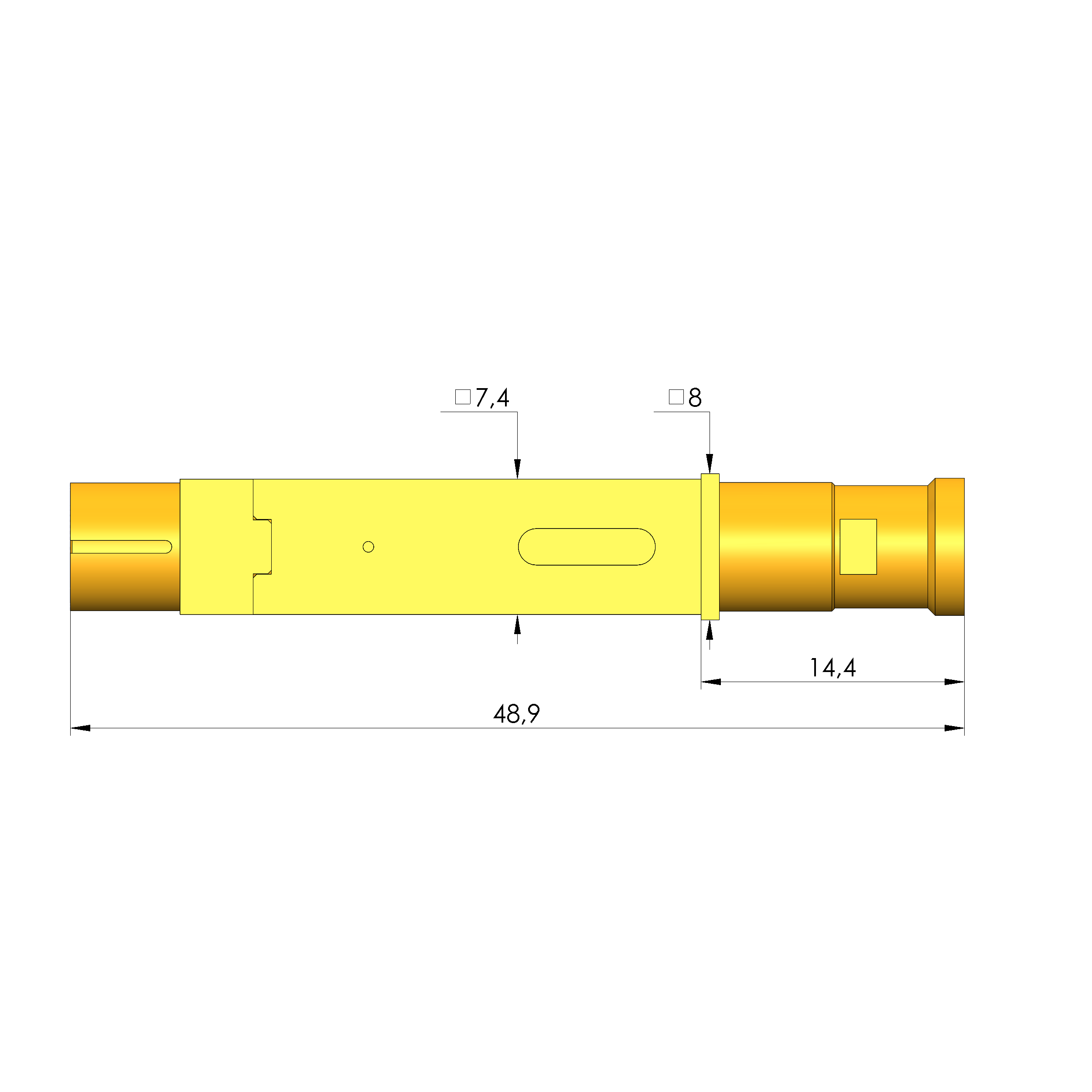

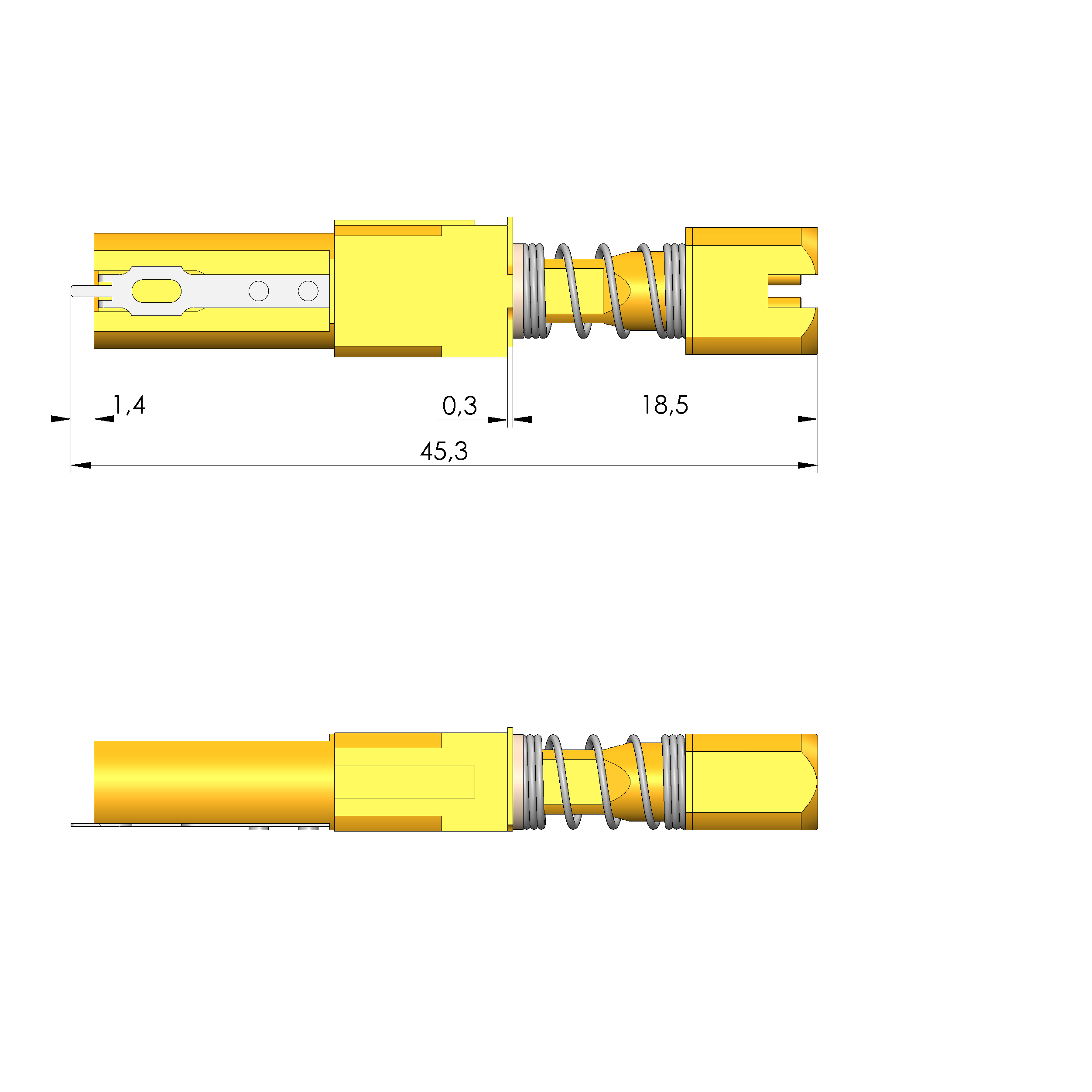

Flat contacts

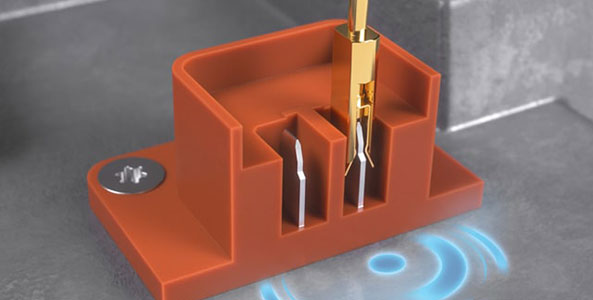

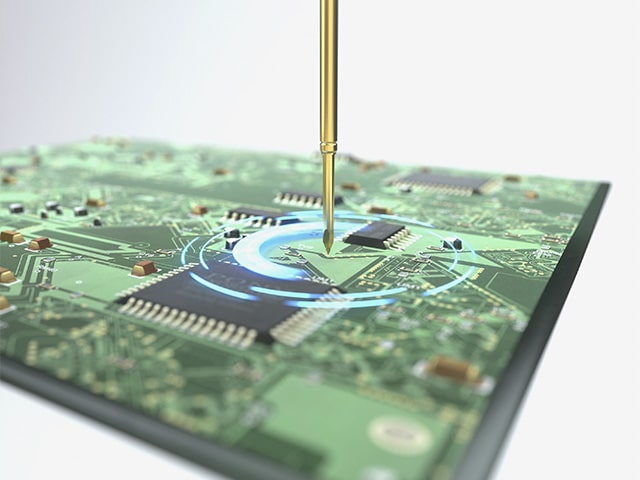

Flat contacts are frequently used in the connector sector. This geometry is extremely economical to produce and is therefore found in large quantities. The terminals can be placed directly on the PCB using automatic placement machines. Another possibility is to place the terminals directly in the connector using an injection moulding process. The flat contacts can be contacted using the INGUN test probes in a small grid size and with standard, as well as four-wire, measurements. INGUN’s patented HKF or VKF series has the advantage of scratch-free testing.

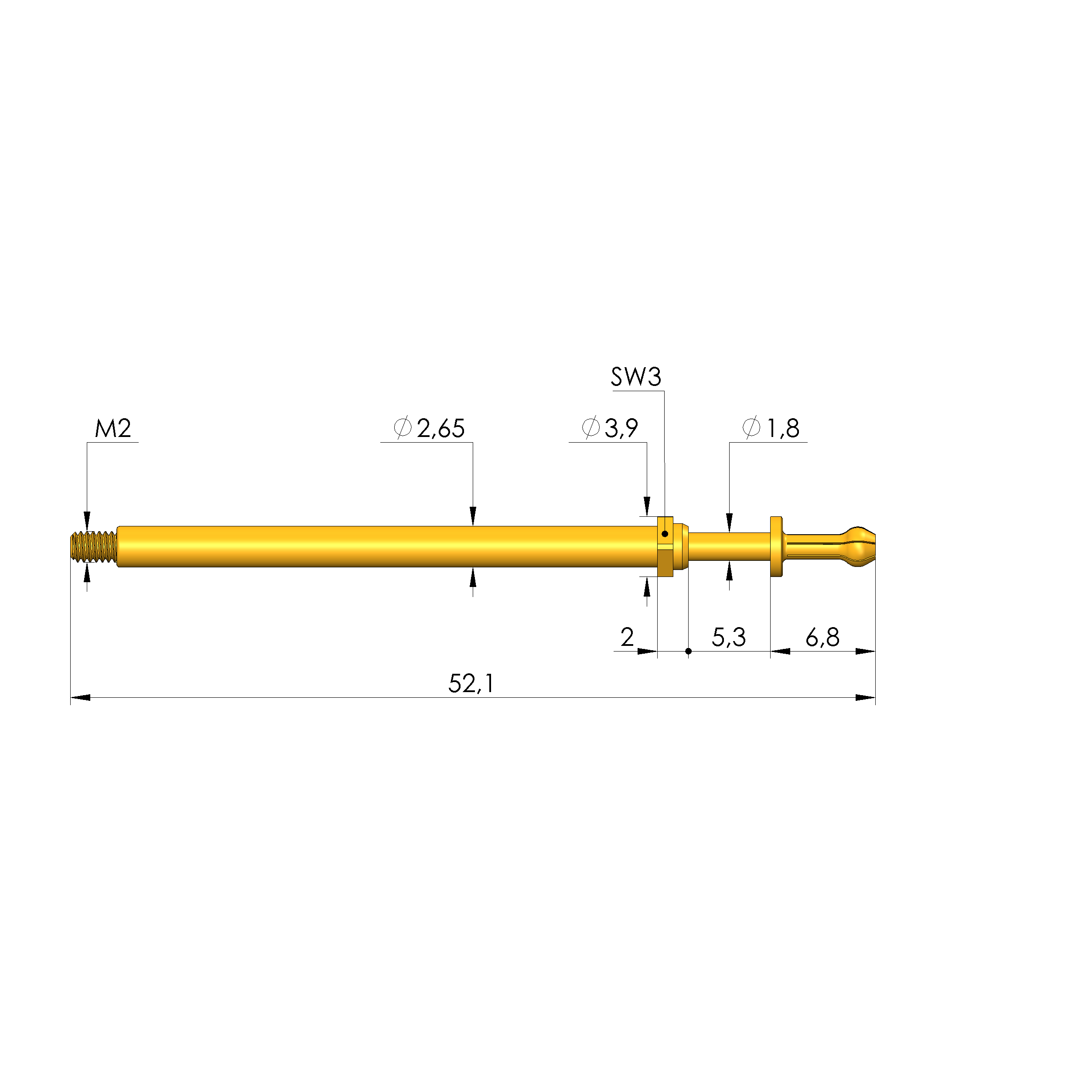

Round contacts

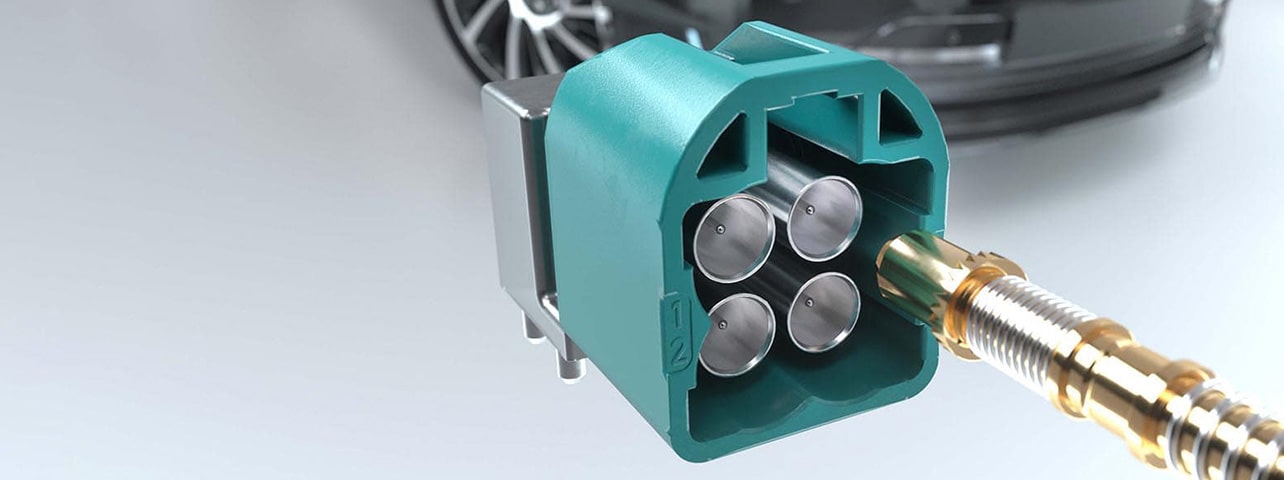

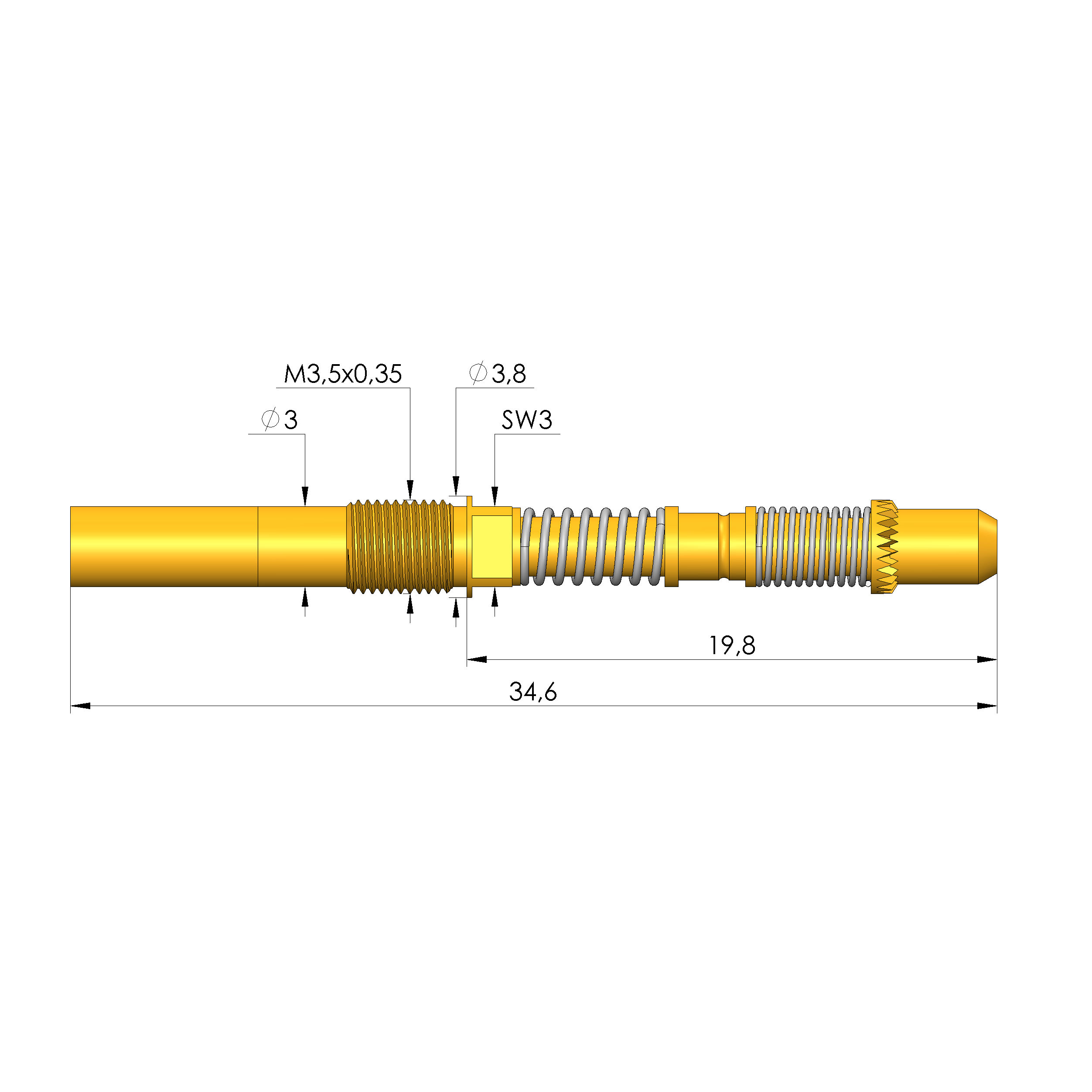

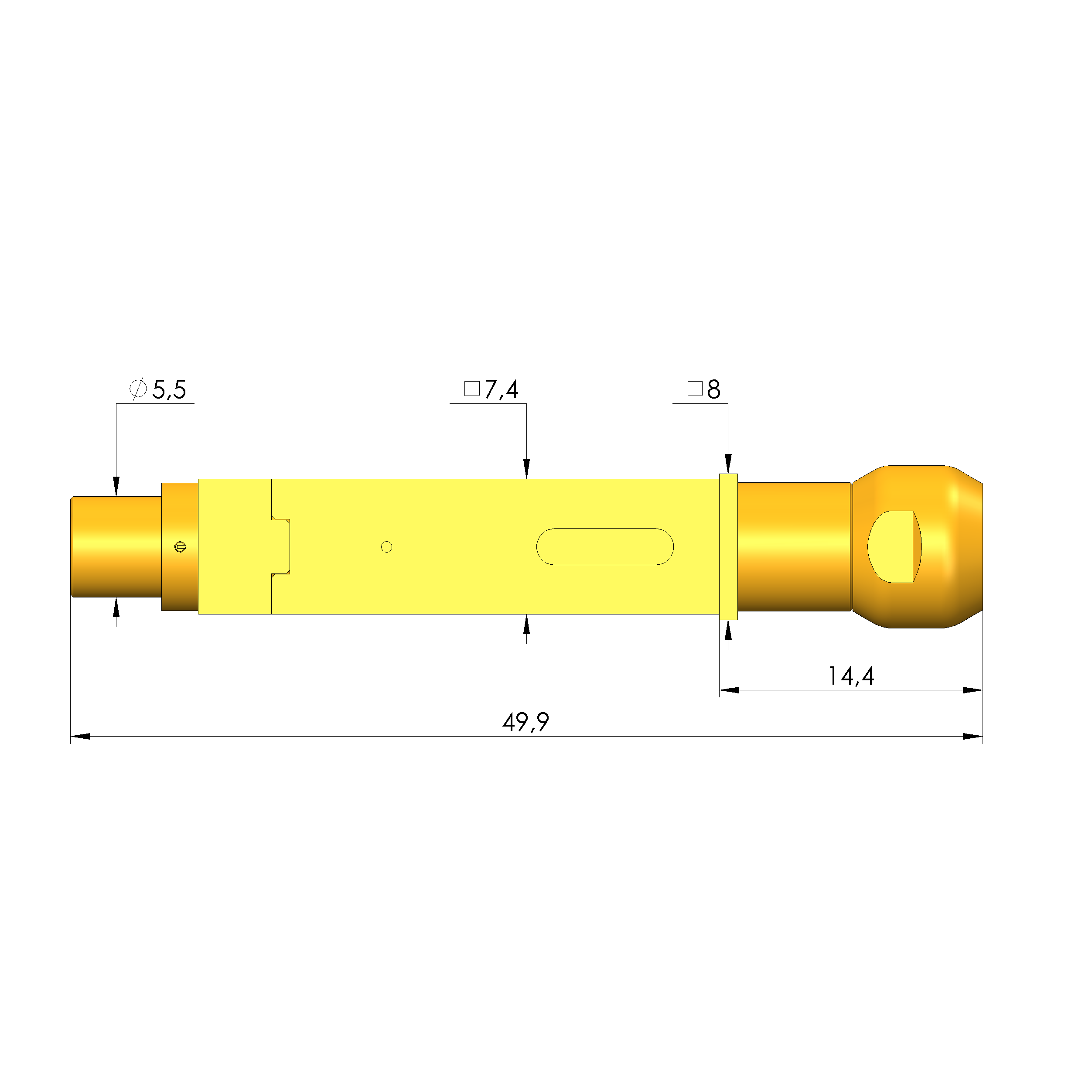

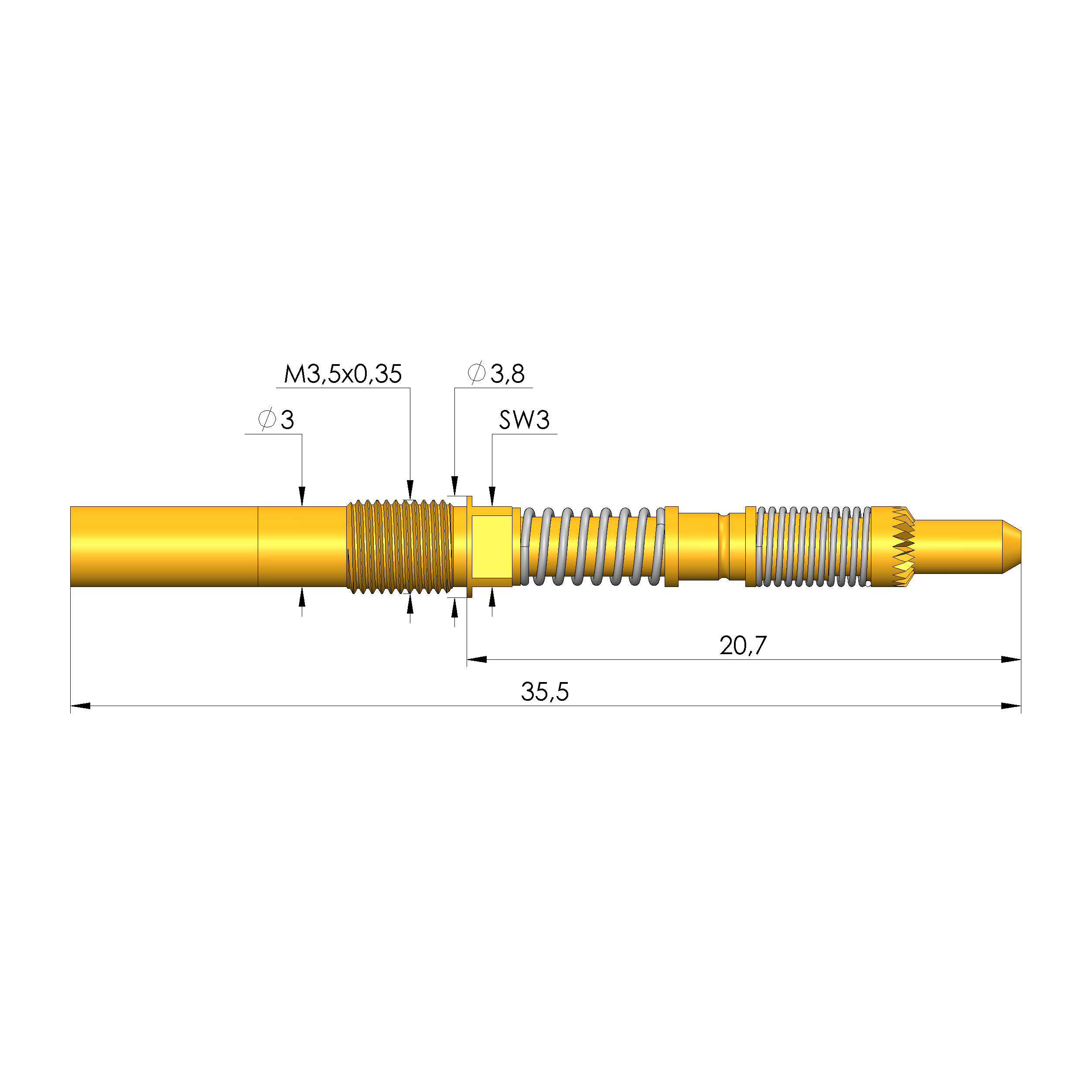

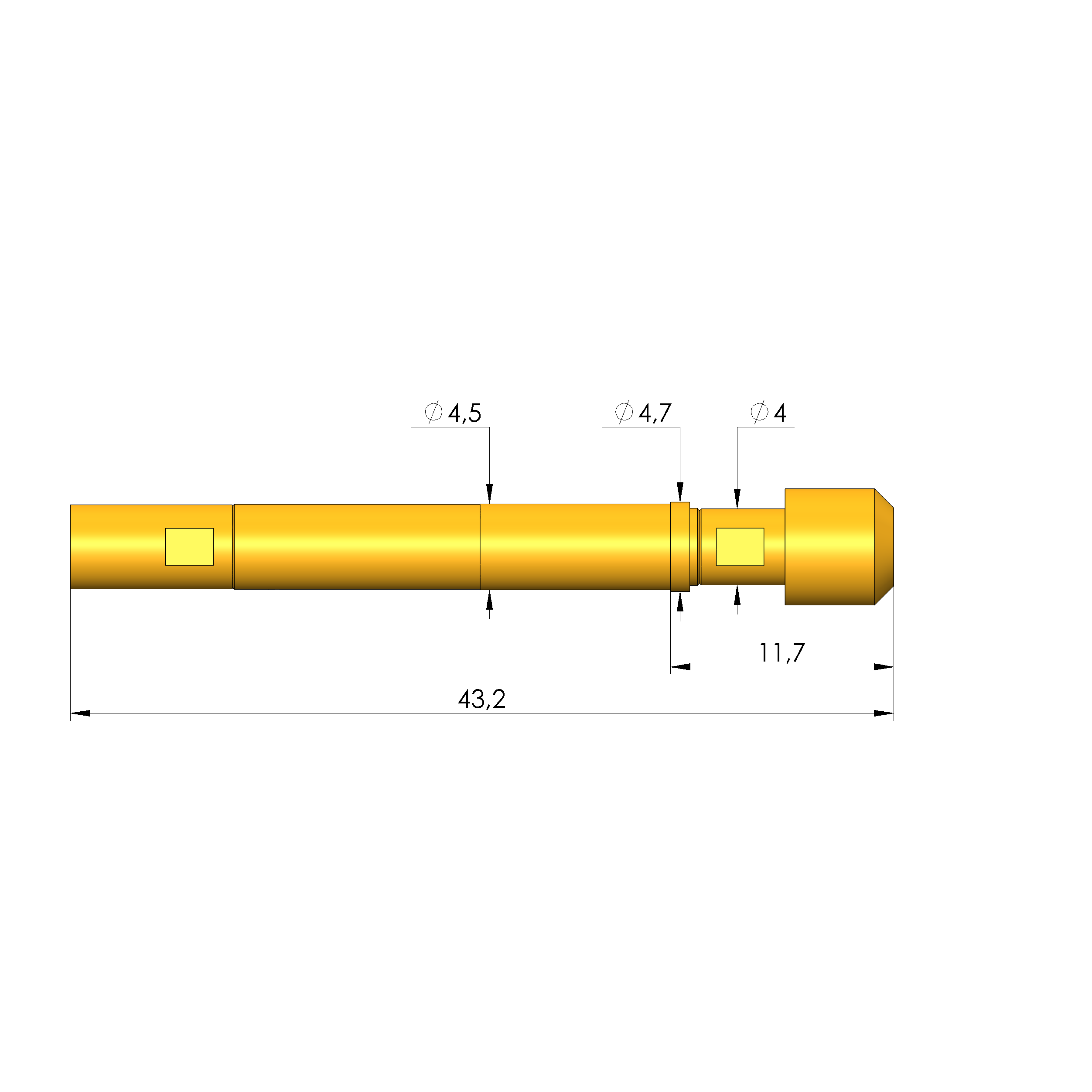

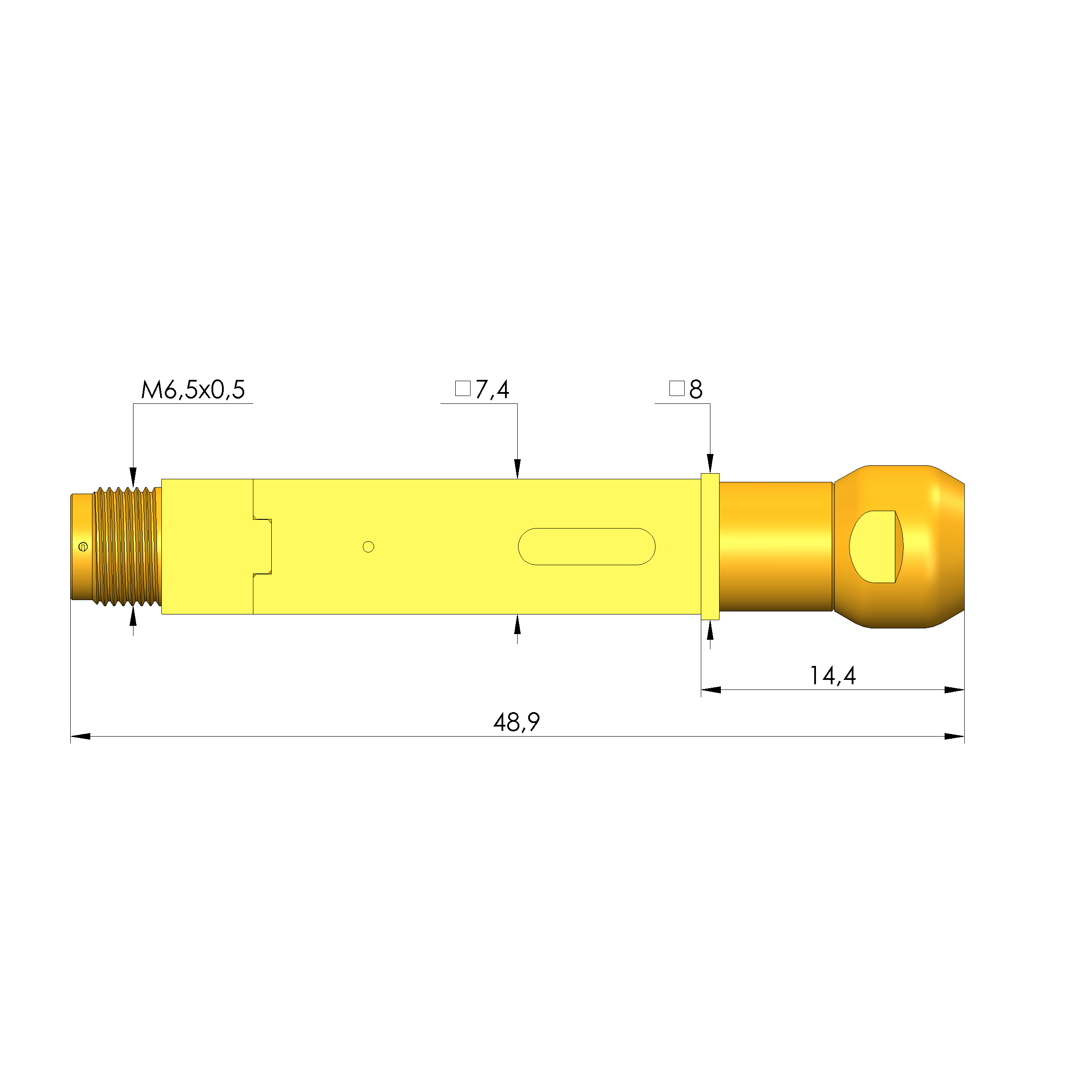

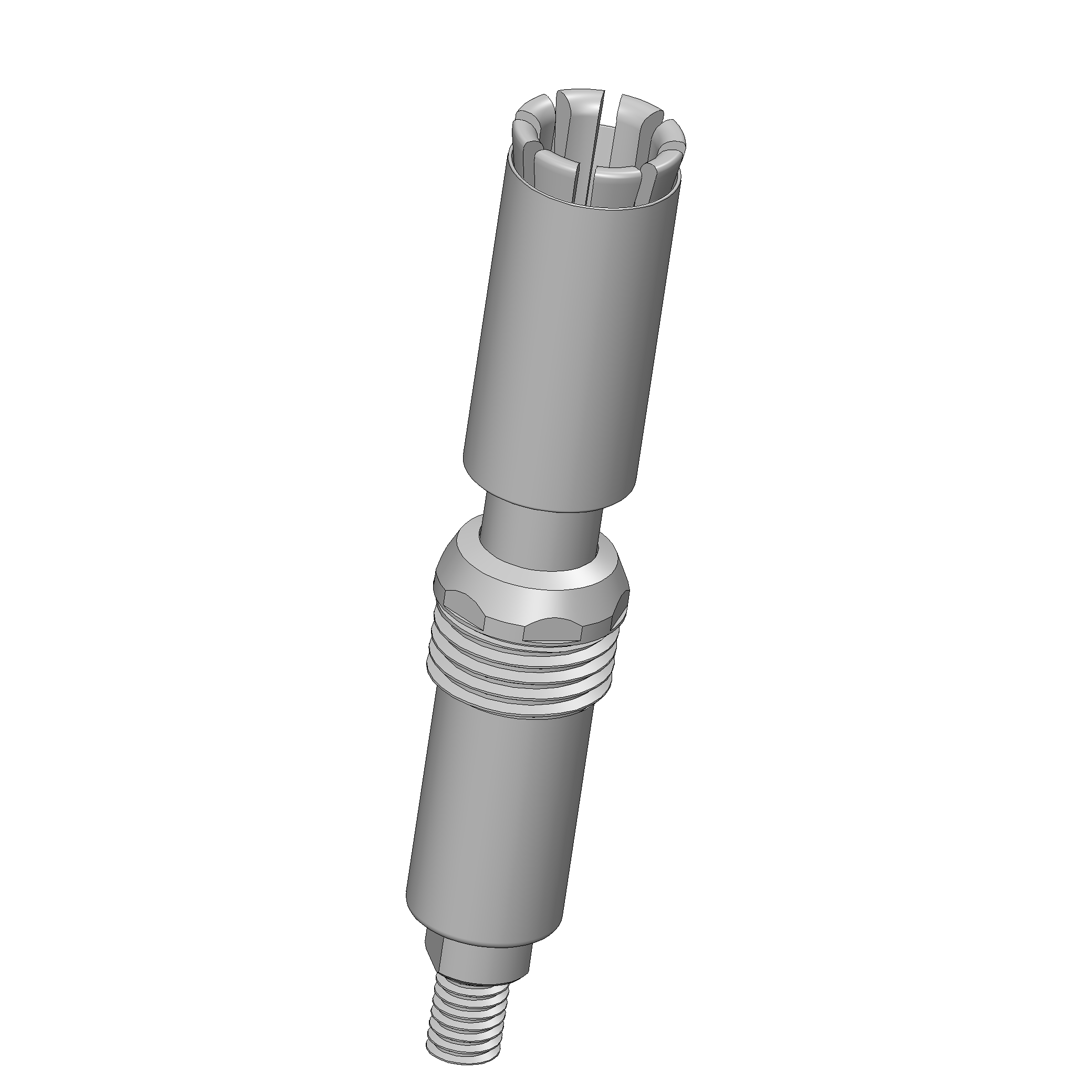

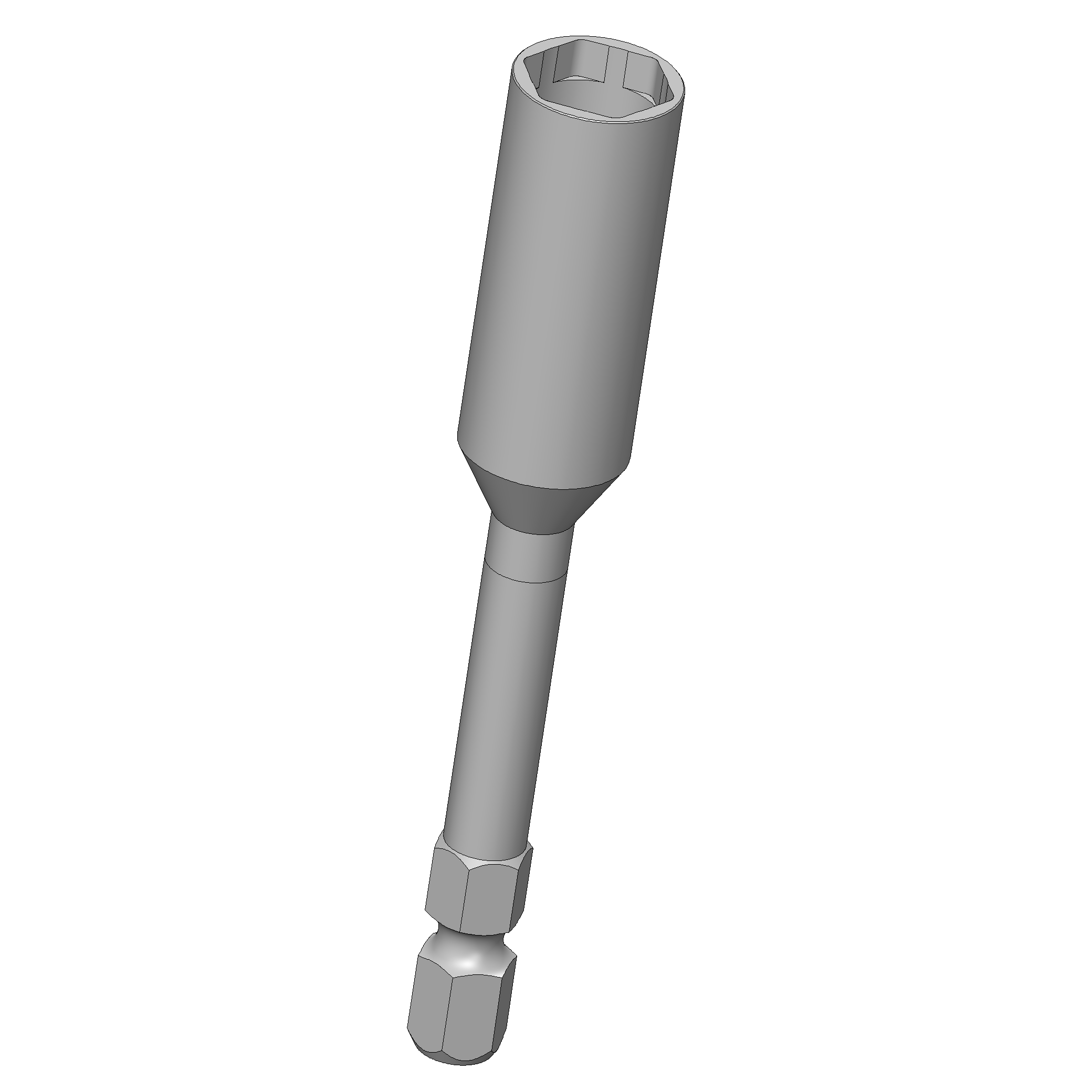

The round contacts in the connectors can withstand high voltages and currents, especially in the field of e-mobility. There are a wide variety of diameters and probe lengths for round contacts. A special feature is the finger guard, which often has to be subjected to a detection test. The round contacts can be contacted using the INGUN test probes in small grid size and with standard as well as four-wire measurements. The patented scratch-free HKR and VKR versions are particularly worthy of mention. Other probes for shielding and integrated thermocouples are also available.

Sockets/terminals

High-current cables are the links between connectors and power consumption units. The cable assemblies are tested for quality by means of a high-current and/or high-voltage test. The accessibility of the terminals is usually difficult for safety reasons, which can complicate the test process. However, INGUN has developed solutions to contact these terminals safely and without scratch.