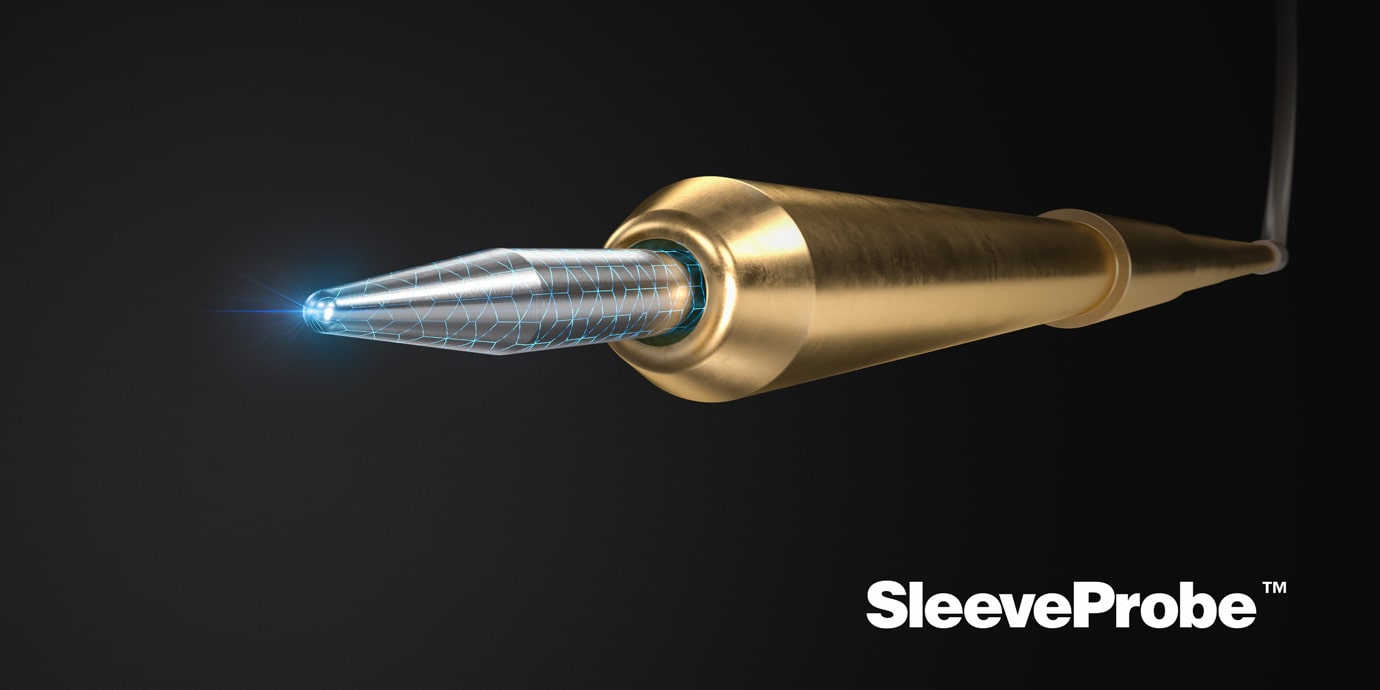

SleeveProbeTM

Innovation that makes a difference

High-performance contacting - even with residues and surface coatings

Conventional fine pitch test probes often reach their limits on hard, contaminated, or coated surfaces. SleeveProbe™, however, delivers the highest contact force on the market at 3 N in a 30-mil pitch.

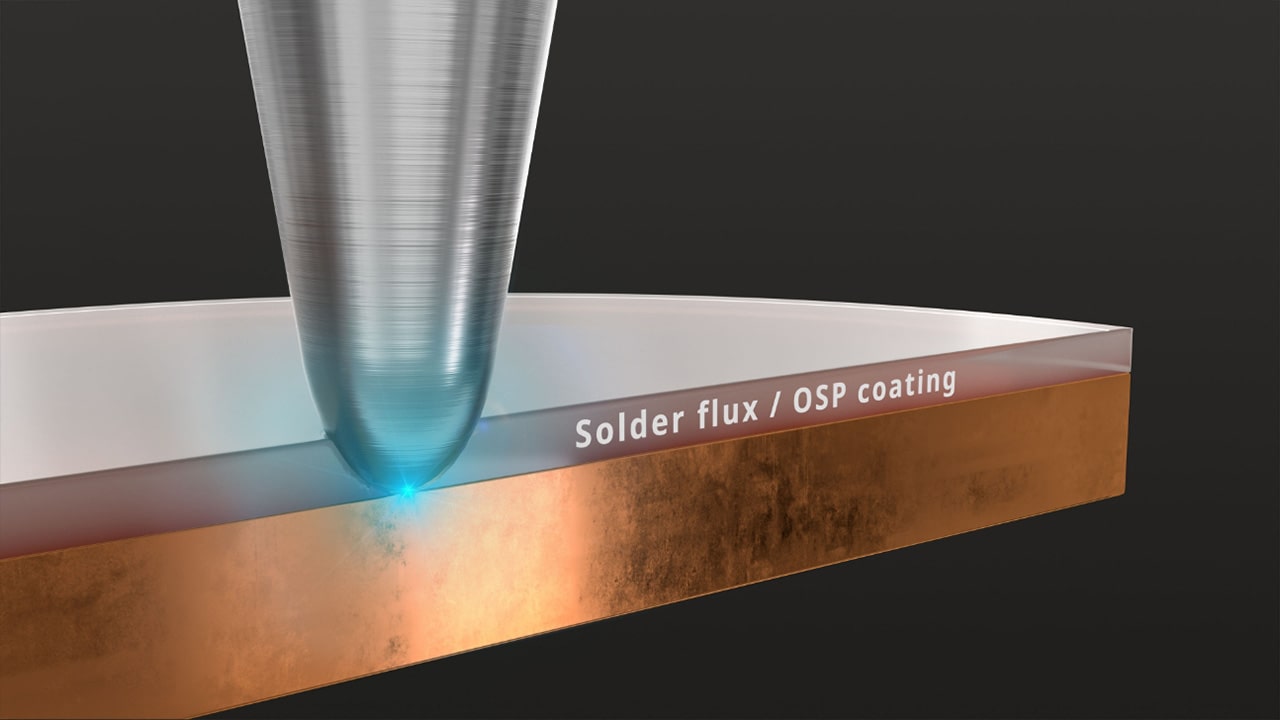

- Penetrates solder flux and OSP coatings effortlessly

- Variable force generation with the same stroke - significantly reduces probe exchanges

- Higher efficiency with lower maintenance and operating costs

Outstanding service life - as robust as a standard test probe

While conventional fine pitch probes are often susceptible to wear, SleeveProbe™ features a robust design and the use of components from our standard test probes on the actuating side.

- Service life comparable to robust 100-mil standard probes

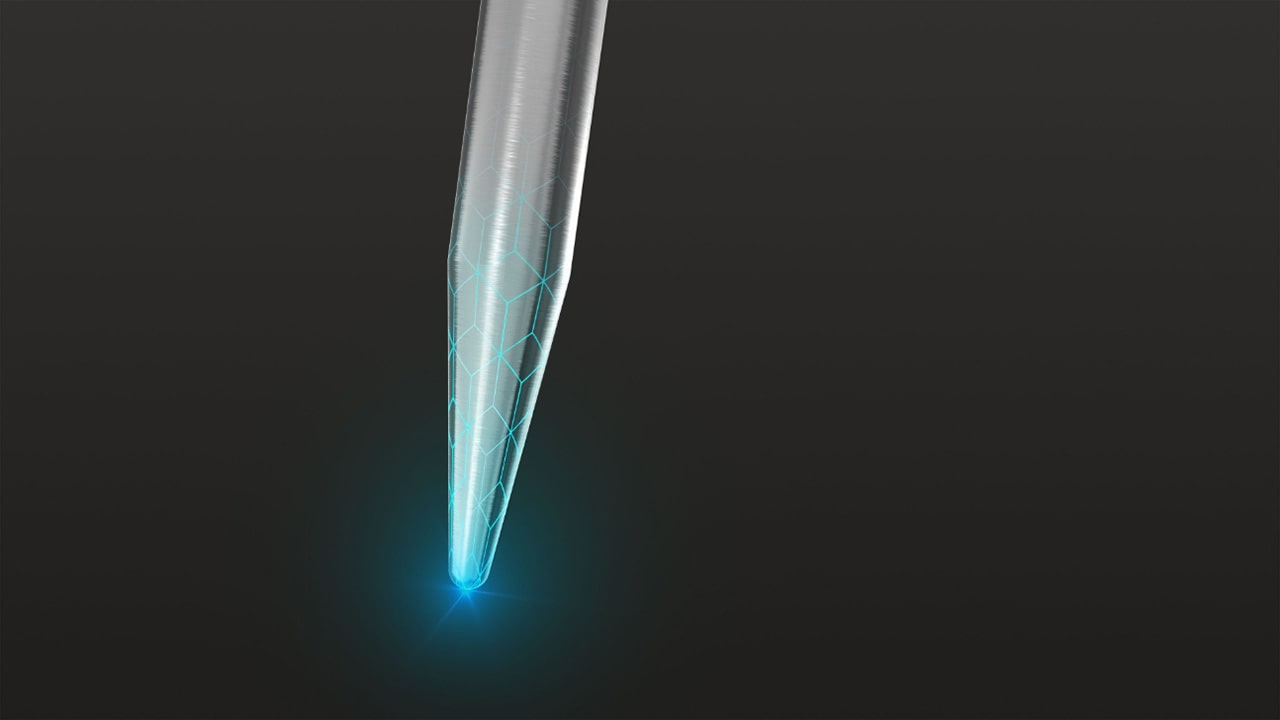

- Durable design thanks to guide sleeve with increased wall thickness

- Low-wear tip made of durable tungsten

Special feature: Thanks to the flexible plunger, tolerances such as angled bores are reliably compensated for in fixture configurations, which has a positive effect on service life.

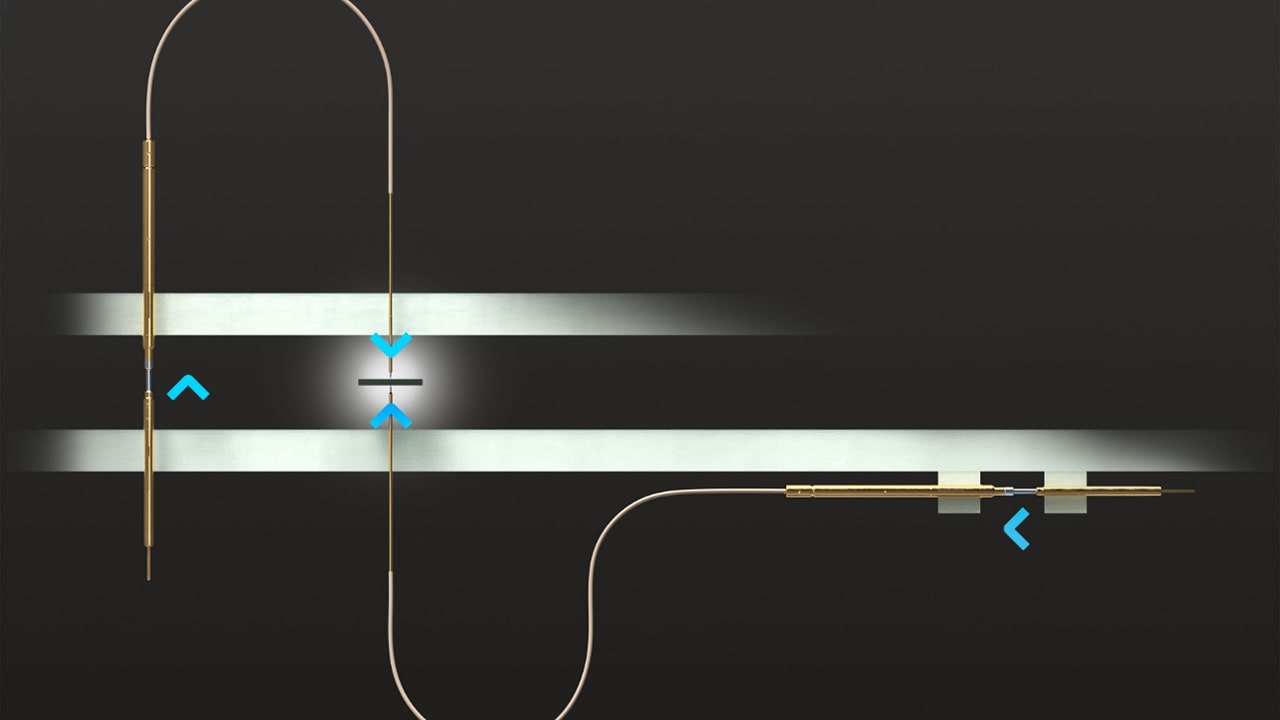

Maximum flexibility in the smallest of spaces - thanks to 360° contacting

Electronic devices are becoming increasingly compact and complex – which not only require smaller components, but also flexible PCB moulds. SleeveProbe™ masters these challenges with ease:

- World’s first test solution for true 360° contacting

- Maximum design freedom thanks to flexible positioning of the test probes

- Independent selection of contacting and actuation direction

SleeveProbeTM

developed for demanding applications

- Ideal for contacting contaminated surfaces (solder flux) or coated surfaces (e.g. OSP coating)

- Perfect for finepitch applications in inline fixtures with the service life of robust 100 mil standard probes

- Enables angled contacting of test points for flexibility in fixture design

- Precise contacting of the smallest test points and realisation of minimal installation heights

- Easy to combine with standard test probes, ideal for multi-stage contacting without additional fixture stroke (e.g. ICT/FCT)