Pneumatic test probes (PKS) are used in many industries and a multitude of applications. These include individual contacting of single test points, activation of switches, contacting of difficult-to-access test points, or creation of interface blocks.

A big advantage is that individual contact points can be contacted without the need for a complete test fixture.

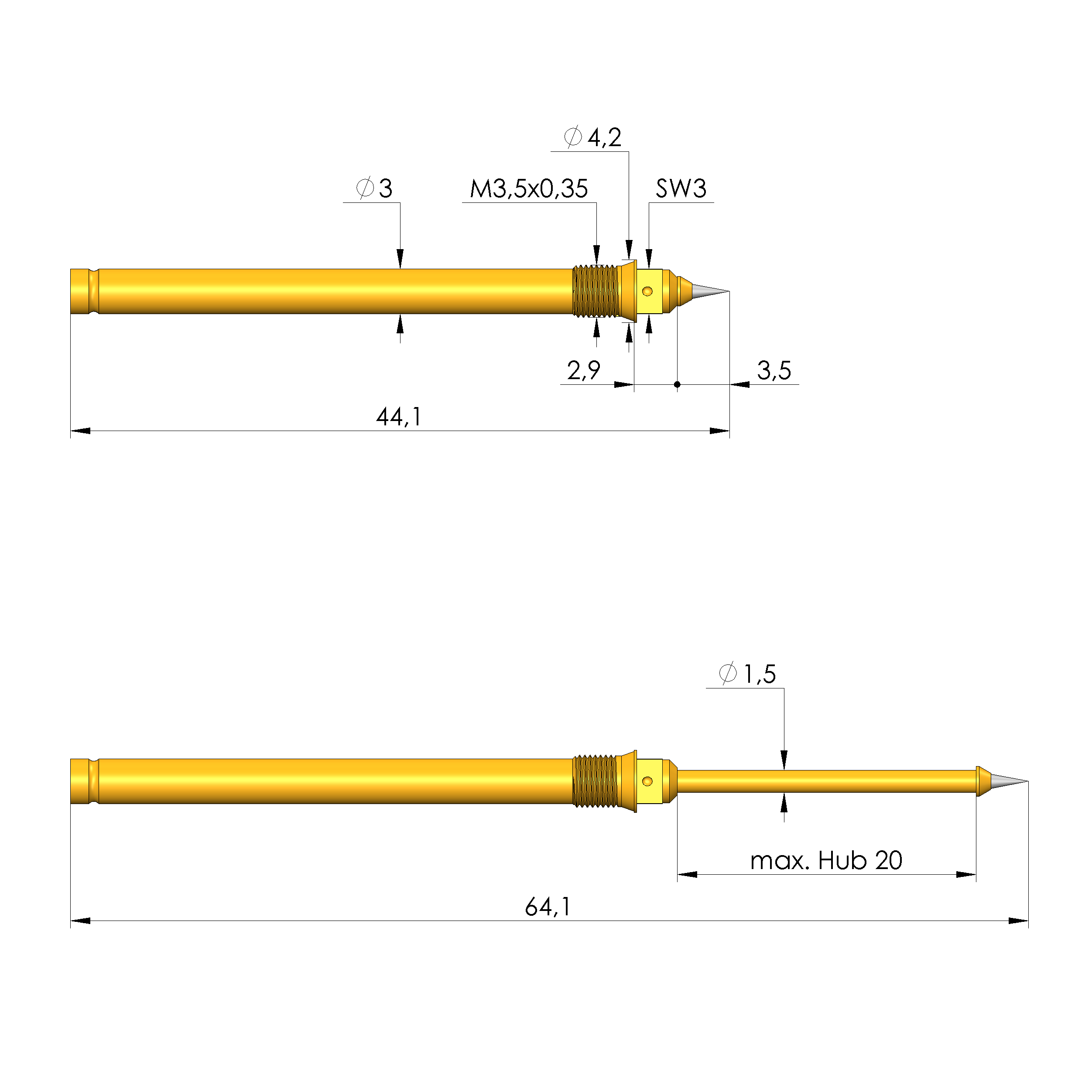

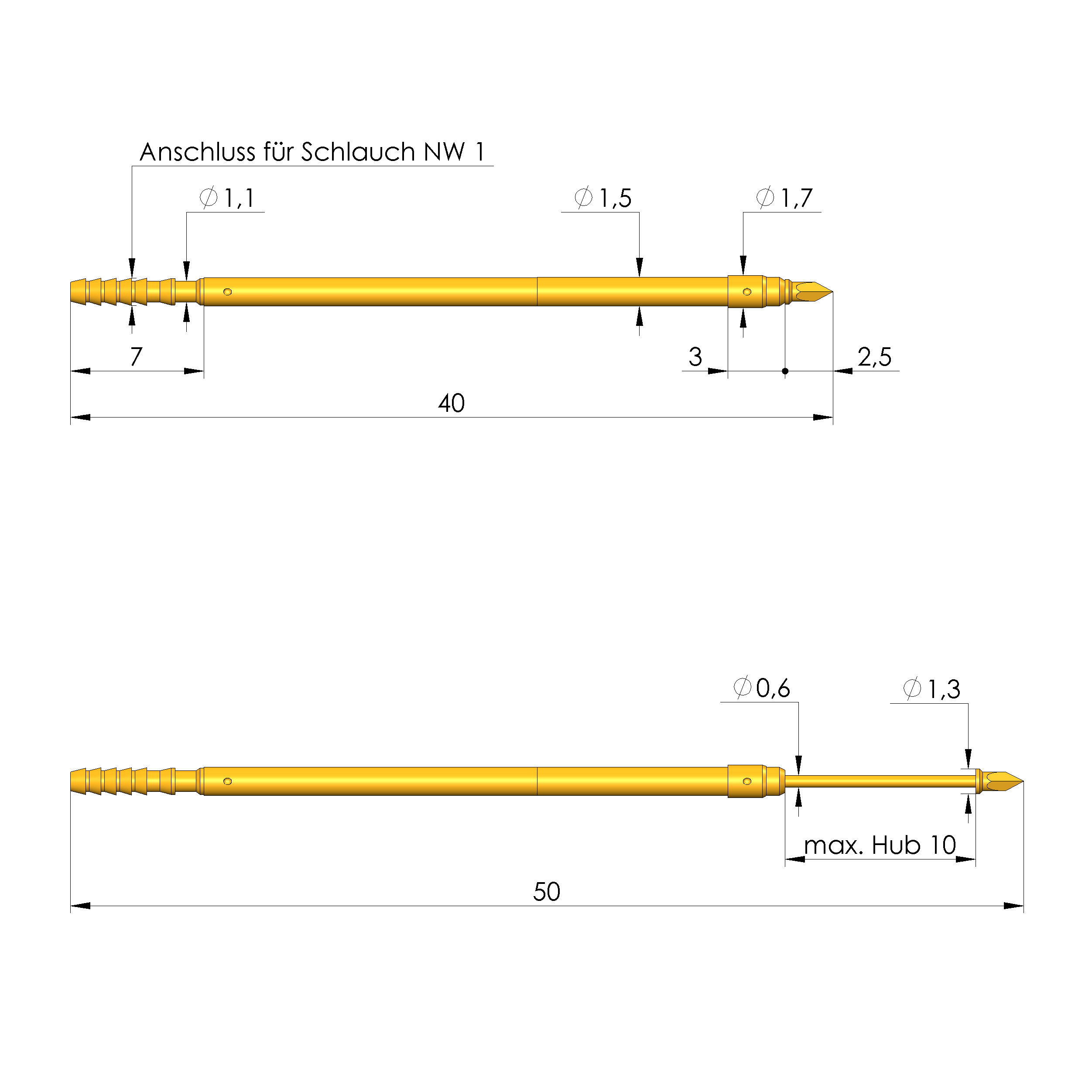

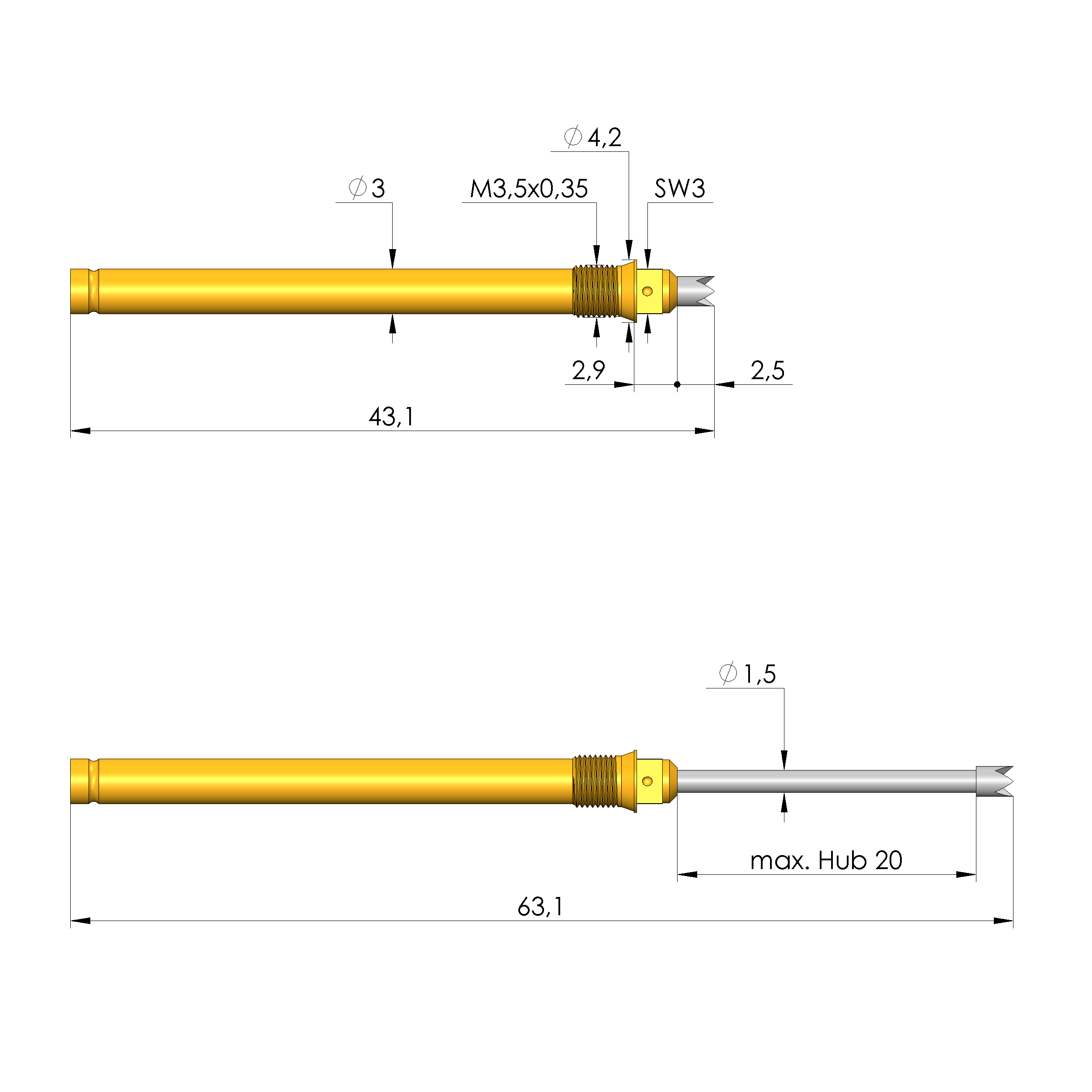

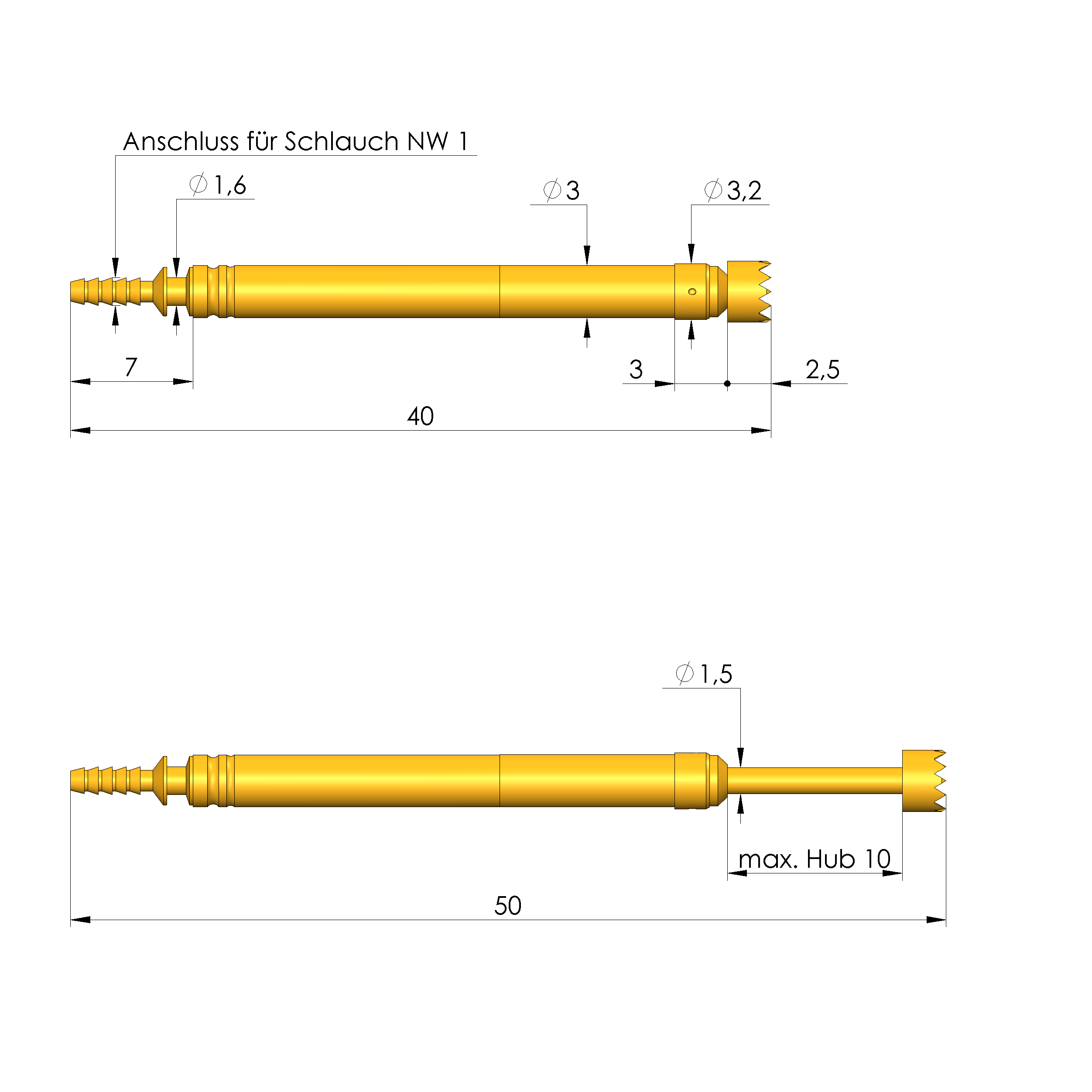

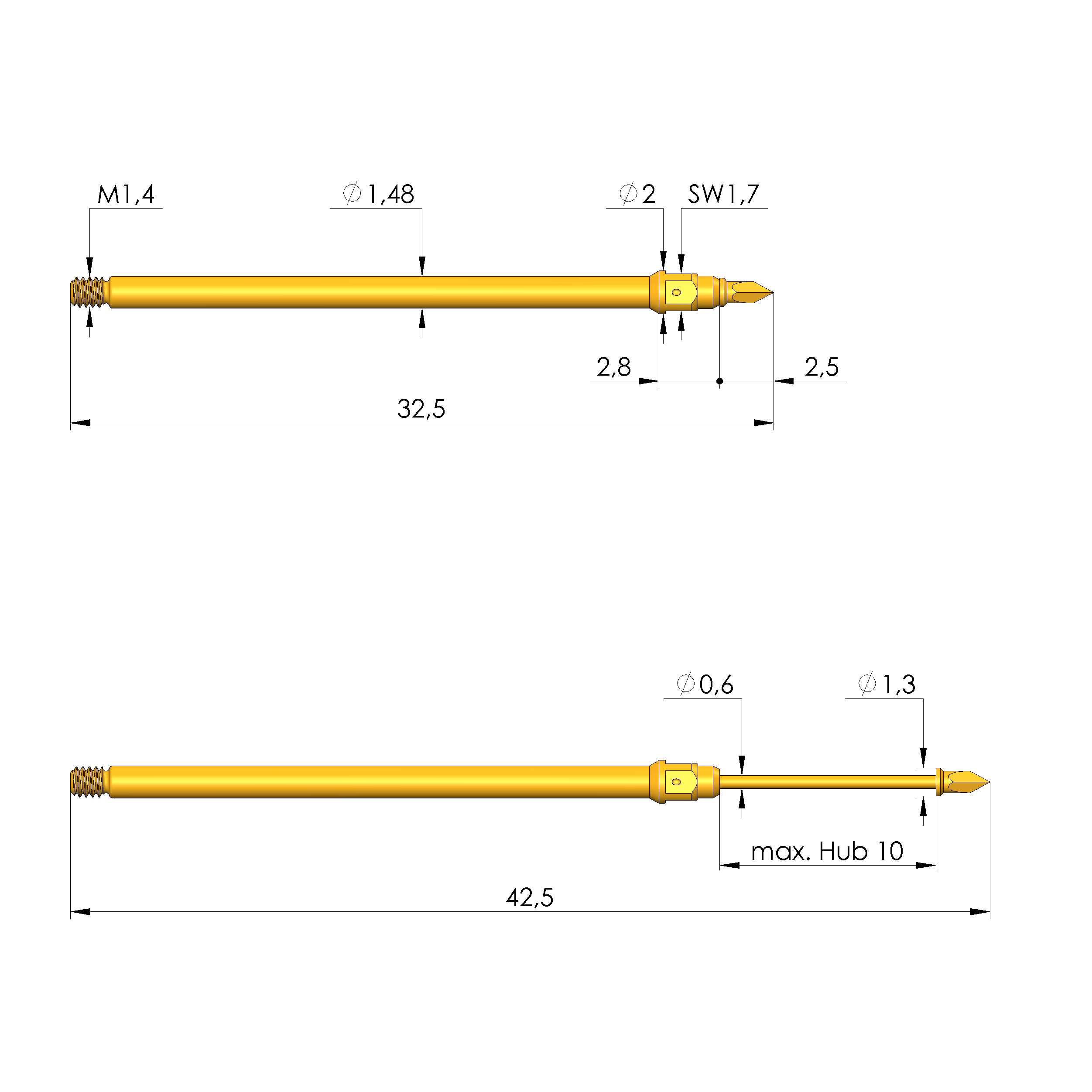

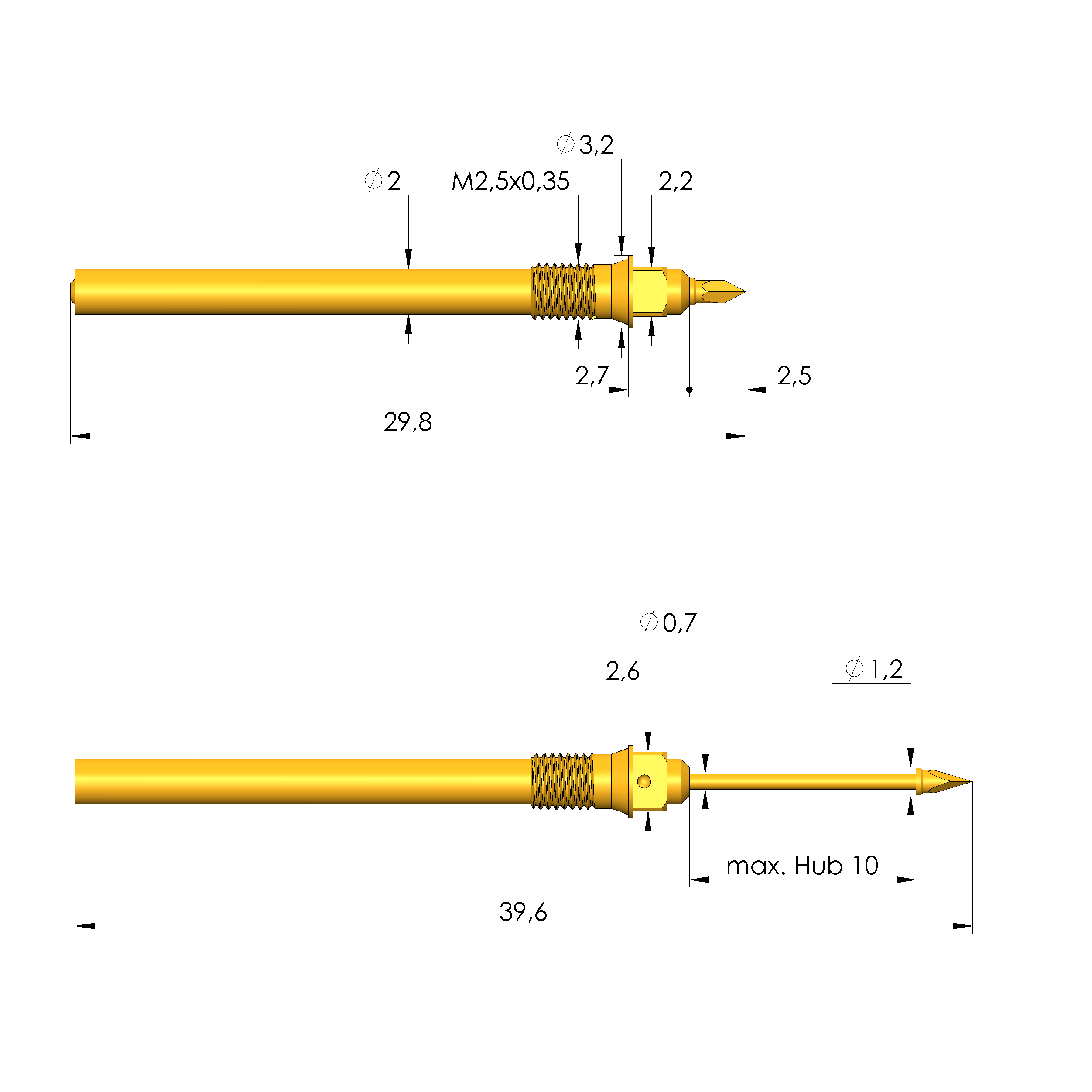

Pneumatic test probes are operated by pressurised air. In the home position the plunger is inside the barrel and is moved outwards when pressurised air is applied. The spring inside returns the plunger back to the home position after the pressurised air is removed.

In contrast to standard test probes (GKS), the further the plunger is extended, the lower the contact force on the probe is - the spring force of the recoil spring works against this.

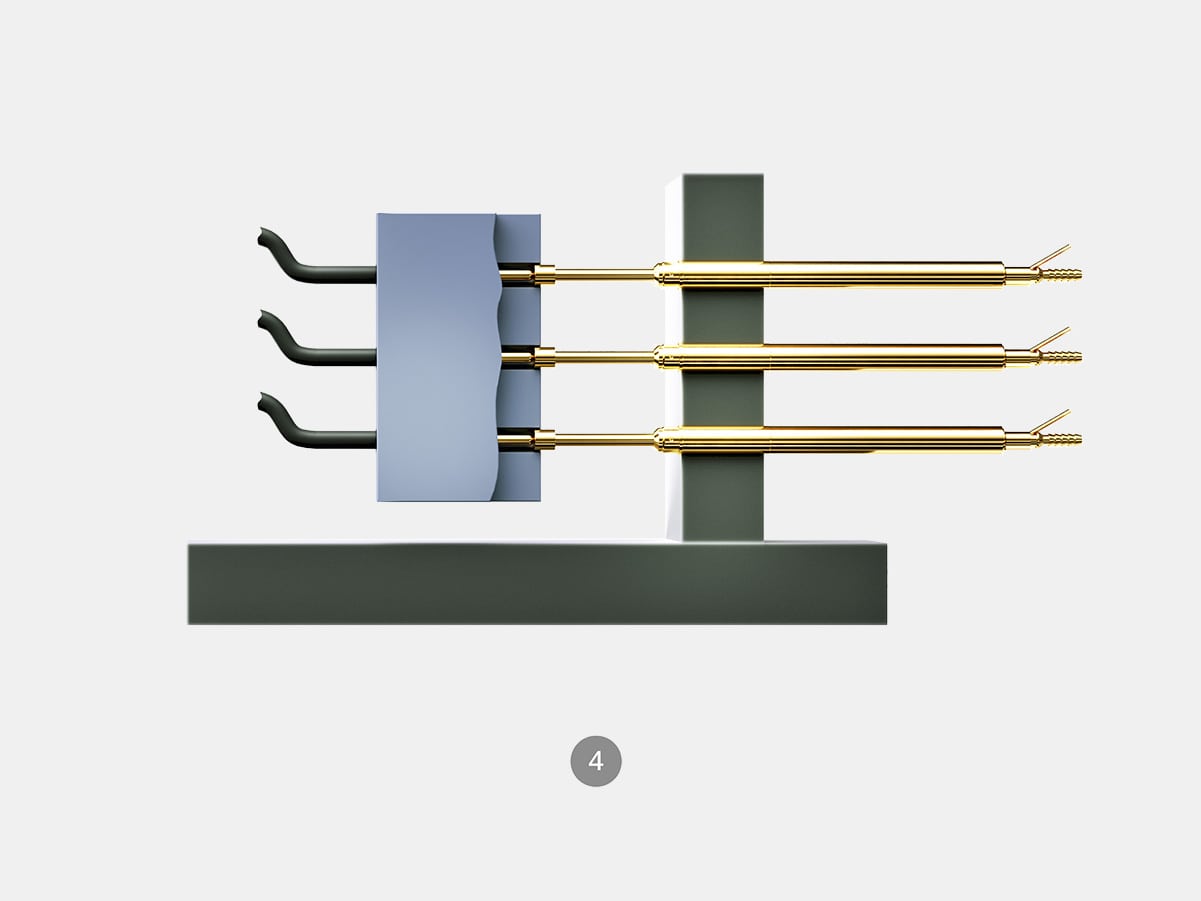

Mounting options and accessories

The installation and electrical connection of PKS are achieved using either a standard receptacle, or a quick-exchange receptacle. When using a quick-exchange receptacle, the cable is either soldered or clipped directly onto the receptacle, and the pressurised air hose is connected to the tail end of the receptacle. This is a real advantage in terms of maintenance, as probes can be exchanged without the need for rewiring, or replacing the hose connection.

Pneumatic test probes from INGUN are designed as partly completed machinery and therefore comply with the applicable requirements of the Machinery Directive 2006/42/EC. Furthermore, PKS can be controlled individually or in groups, which allows the creation of individual test sequences. For this purpose INGUN offers a wide range of accessories.