Manual test fixtures from INGUN are available in several series and models which differ in terms of use, maximum permissible contact force, parallel stroke, size, and service life.

Depending on the assembly, quantity and variety of versions, customers receive solutions optimally matched to their needs.

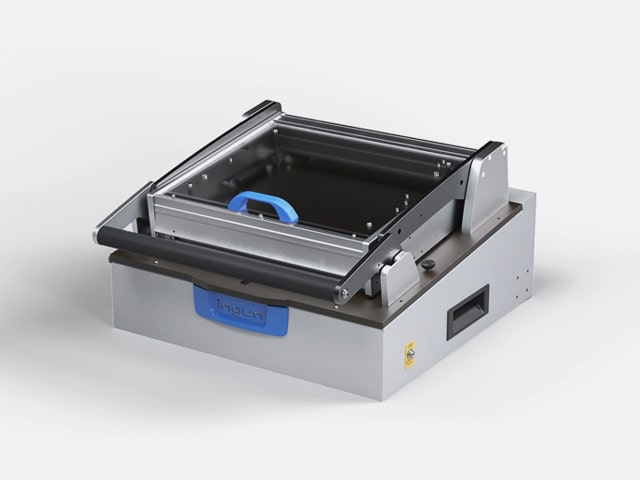

MA xxx series:

Manual test fixtures for batch testing

Test fixtures in the MA xxx series are suitable for contacting or flash programming of electronic units with small quantities (batch testing) and a high number of versions. The test fixtures are designed as an interchangeable kit system, are connected to an existing test system, and are operated with exchangeable kits that are specially designed for the electronic functional unit to be tested. They boast the following features:

- Interchangeable kit system

- Pressure frame with open sides

- Stackable, open bottom, fully removable housing

- Freely definable internal interface

- Exchangeable kits available as standard and ESD versions, can be set up quickly without tools and can be used without readjustment

- Pressure frame unit and probe plate unit can be screwed together to form a unit with protected probe field (for storage/transport)

- Service life: 300,000 load cycles (under laboratory conditions)

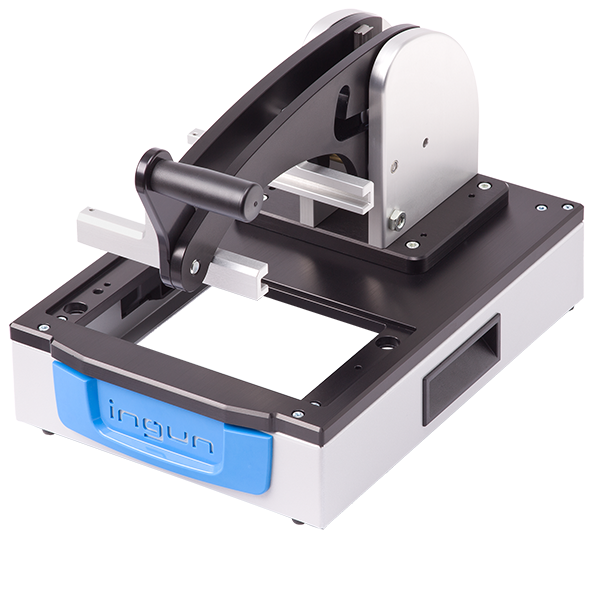

MA 20xx series:

Manual stand-alone test fixtures for series testing

Test fixtures in the MA 20xx series are suitable for contacting electronic units such as printed circuit boards (PCBs) with medium quantities (series testing) and a small number of versions. The test fixtures are designed as a single system without an internal interface, are connected to an existing test system, and are operated with permanently installed exchangeable kits that are specially designed to for the electronic assembly to be tested. They have the following performance features:

- Single system without internal interface

- High contact force of up to 2,000 N

- Energy-saving, shock-absorbing opening mechanism

- Permanently mounted exchangeable kit

- Available with and without test system interface

- Service life: 500,000 load cycles (under laboratory conditions)

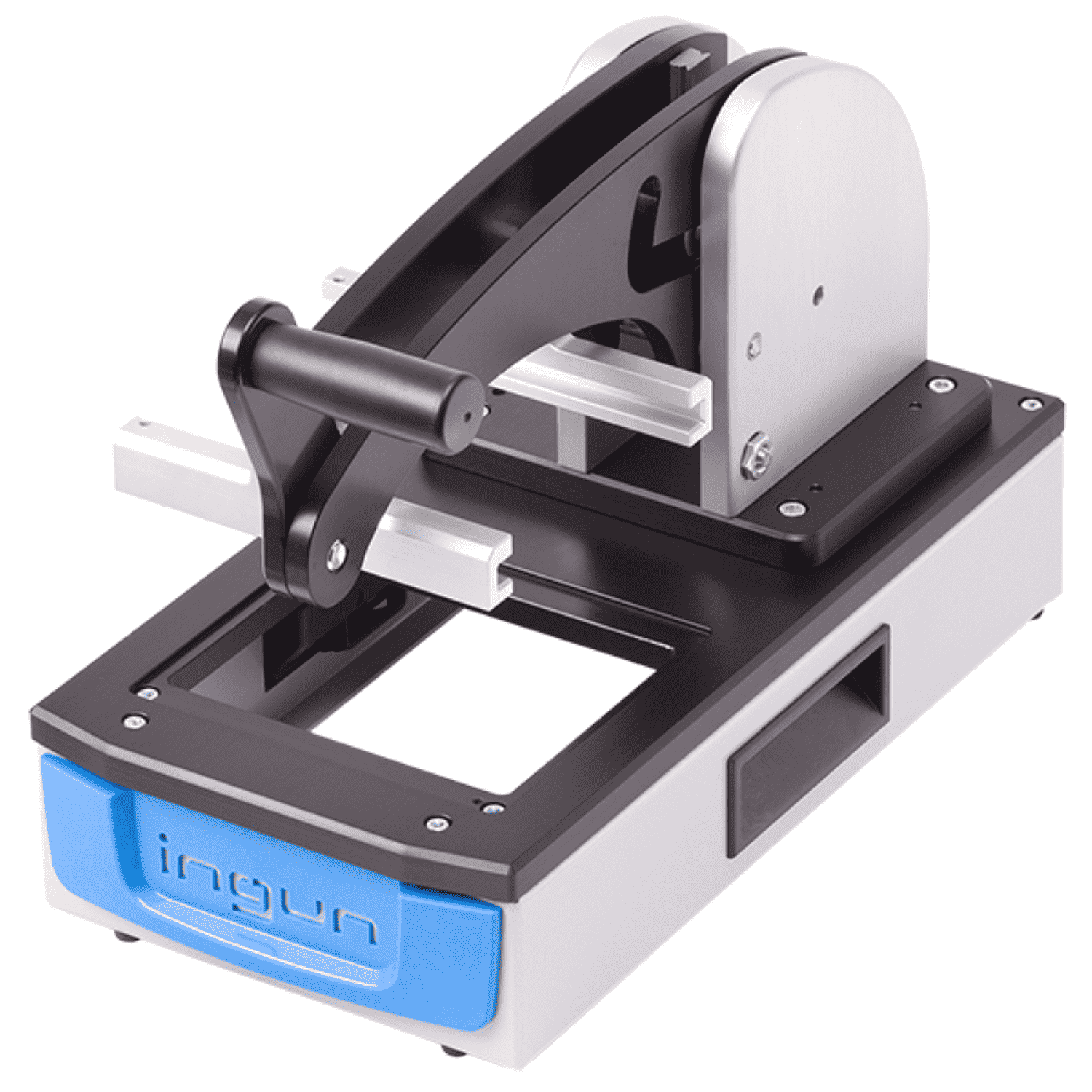

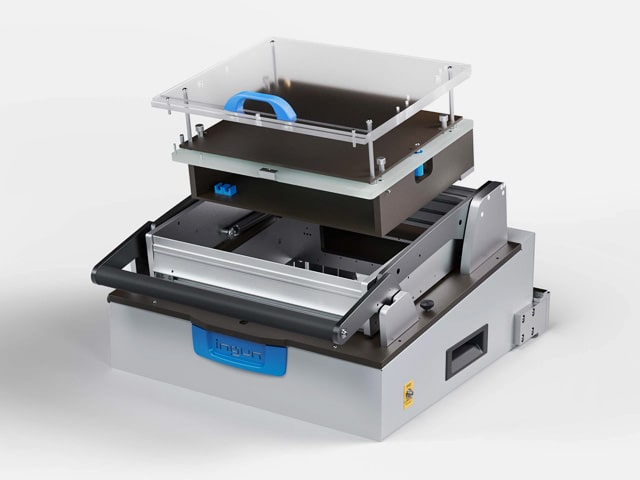

MA 21xx series:

Manual interchangeable test fixture for series testing

Test fixtures in the MA 21xx series are suitable for contacting electronic modules with medium quantities and a high number of versions. The test fixtures are designed as an interchangeable kit system, are connected to an existing test system, and are operated with interchangeable kits that are specially designed for the electronics assembly to be tested. They boast the following features:

- Interchangeable kit system

- High contact force of up to 2,000 N

- Energy-saving, shock-absorbing opening mechanism

- Modularly configurable internal interface

- Exchangeable kits can be used without readjustment

- Available with and without test system interface

- Pressure frame unit and probe plate can be screwed together, to form a unit with protected probe field (for storage/transport)

- Service life: 500,000 load cycles (under laboratory conditions)

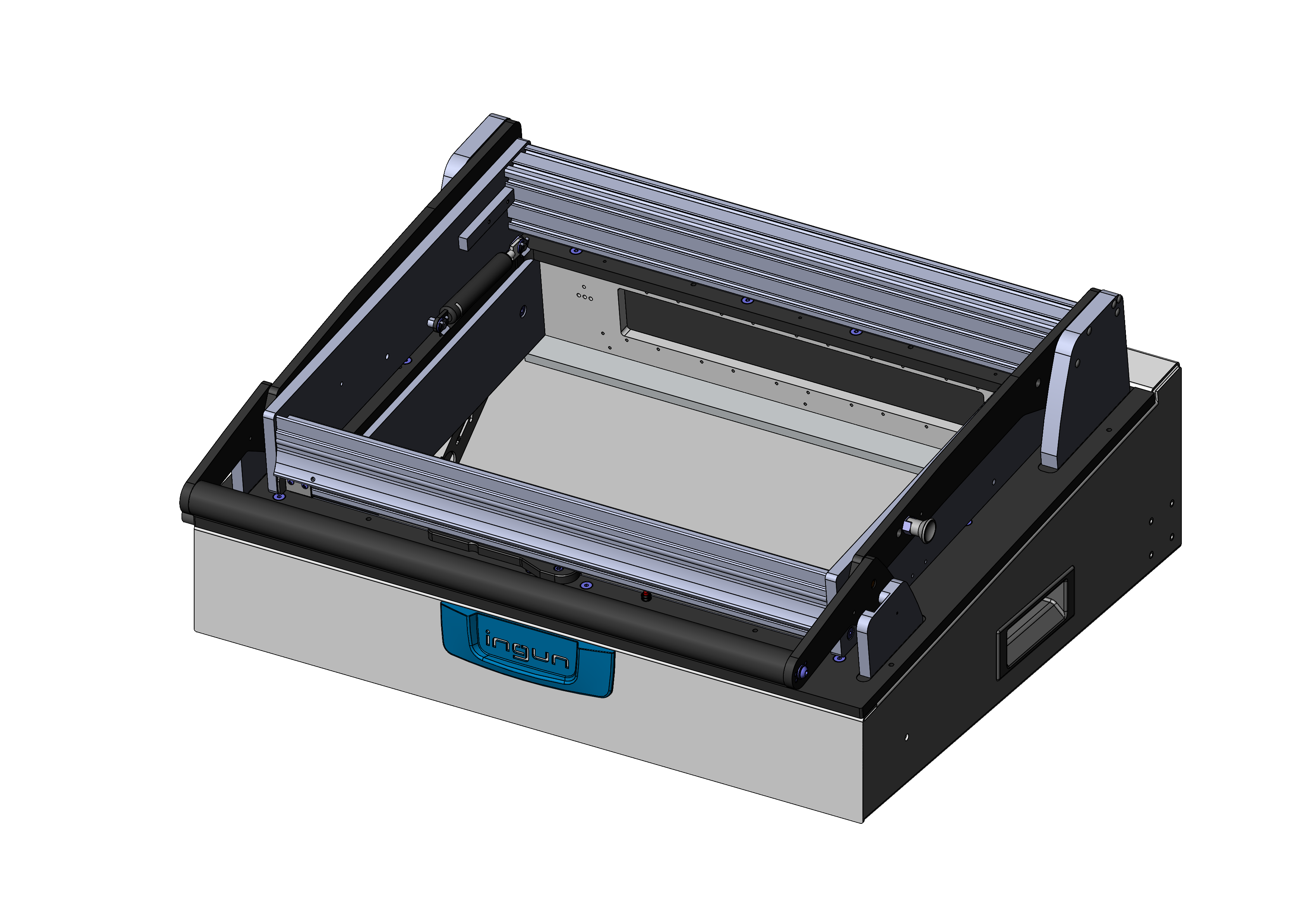

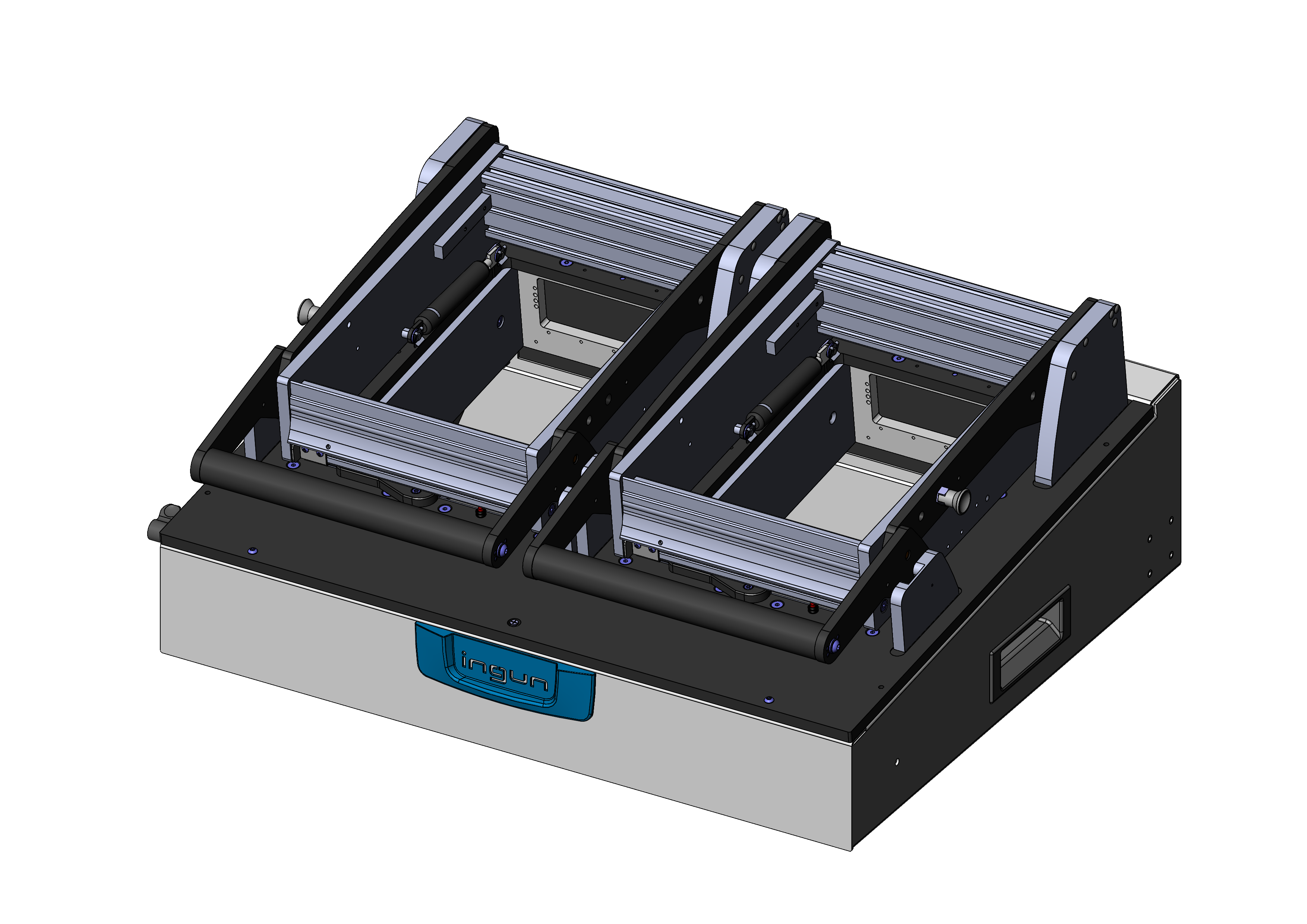

MA 32xx series:

Manual interchangeable kit test fixtures for mass testing

Test fixtures of MA 32xx series are suitable for contacting electronic units such as printed circuit boards (PCBs) with high quantities (mass testing) and a large number of versions. The test fixtures are designed as interchangeable kit systems, are connected to an existing test system, and operated with exchangeable kits that are specially designed for the electronic assembly to be tested. They boast the following features:

- Robust drive unit optimised for use in harsh test fields

- Interchangeable kit system

- High contact force of up to 2,000 N

- High parallel stroke of 22 mm

- Energy-saving, shock-absorbing opening mechanism

- Modularly configurable internal interface

- Exchangeable kits, can be installed quickly without tools or readjustment

- Pressure frame unit and probe plate can be screwed together to form a unit with protected probe field (storage/transport)

- Service life: 2,000,000 load cycles (under laboratory conditions)

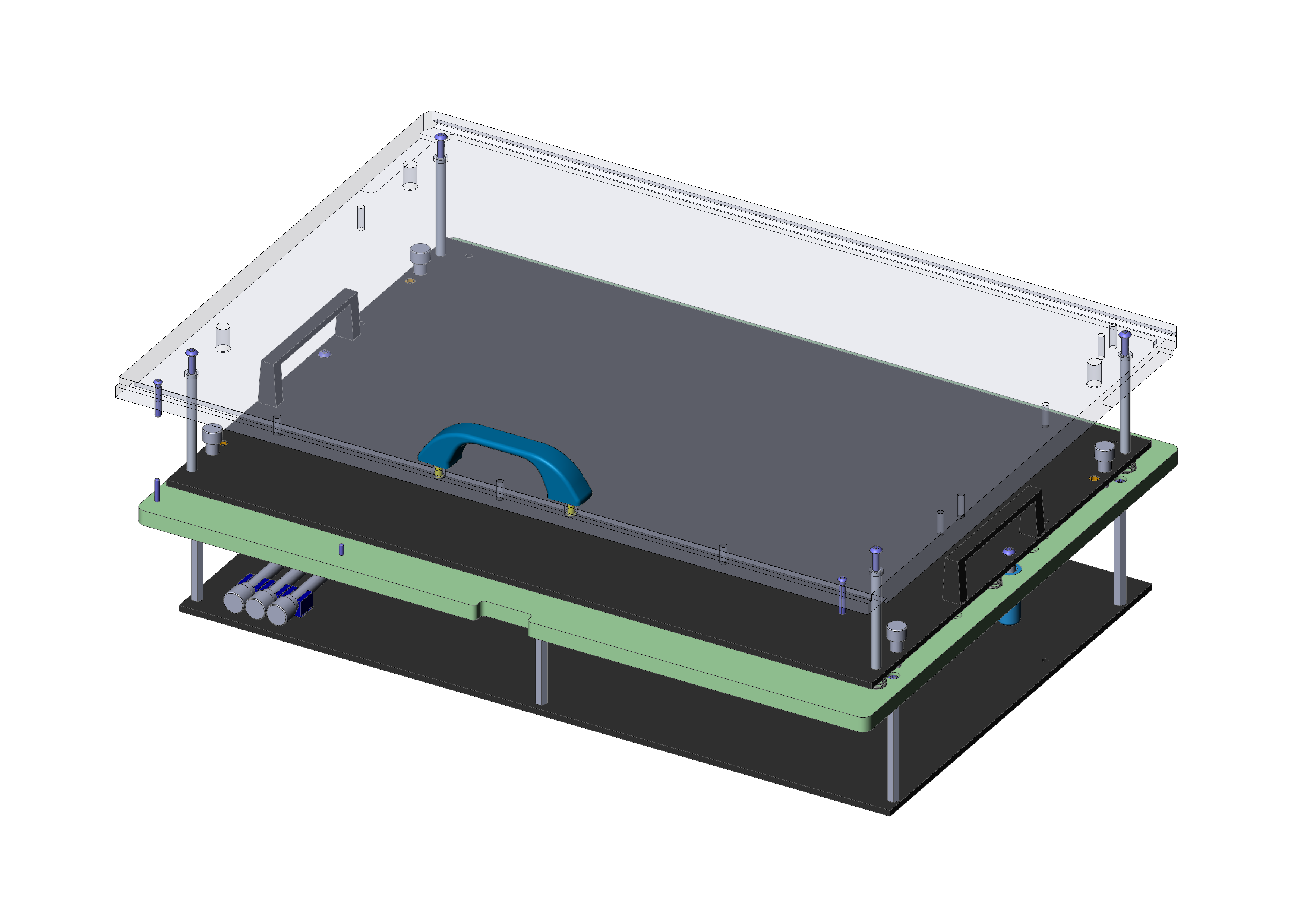

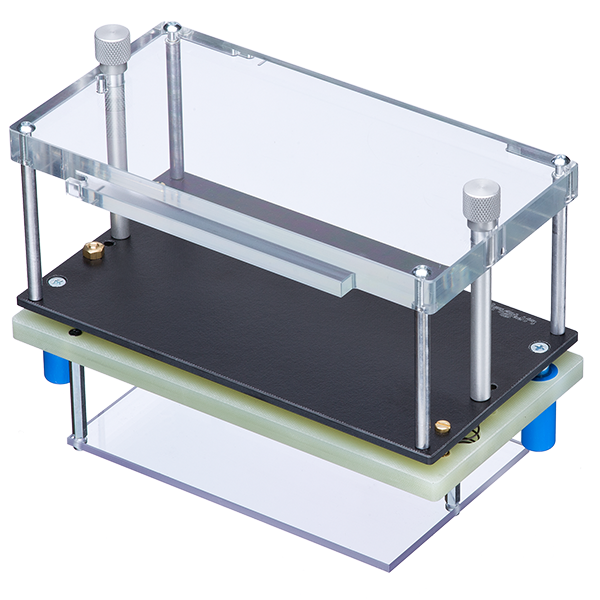

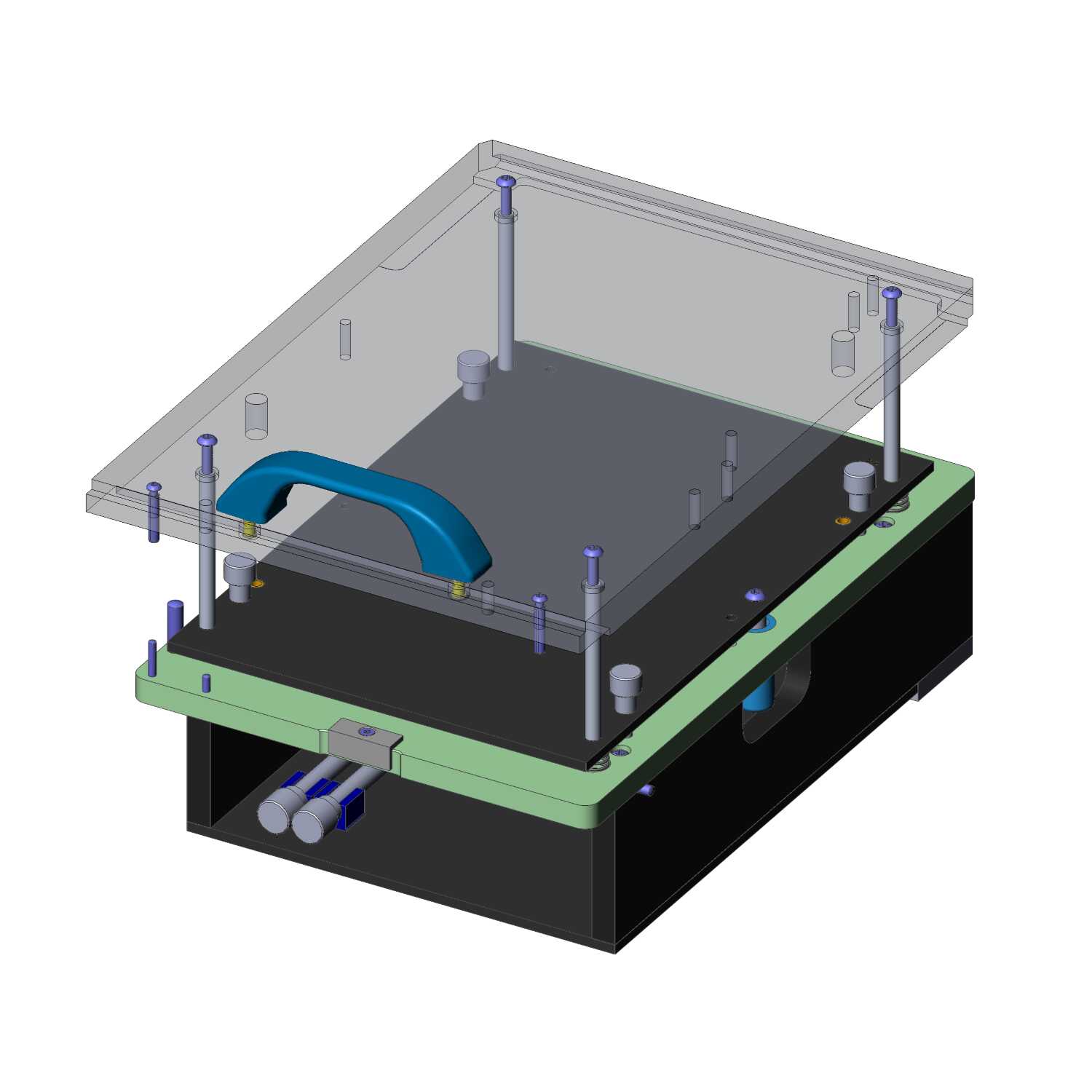

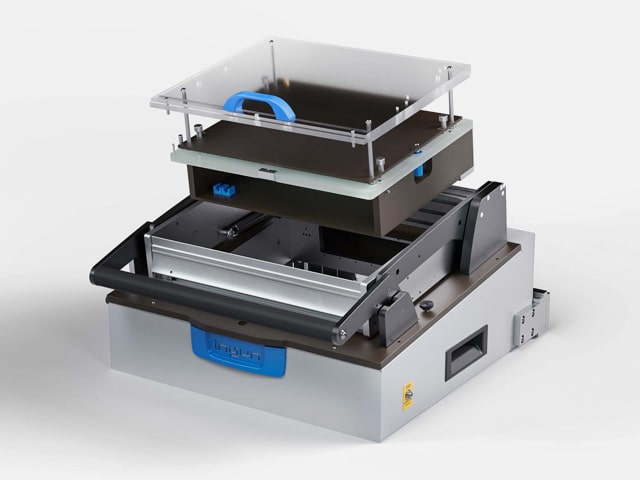

Maximum flexibility in fixture construction

Exchangeable kits (ATS) are available for the manual test fixtures in standard, ESD, high-frequency versions, which can be exchanged in interchangeable test fixtures quickly, without tools and without readjustment. The exchangeable kits consist of the probe plate unit and the pressure frame unit.

The probe plate unit contains the moving plate, the probe plate, the wiring protection plate and, depending on the version, an internal interface which can be configured with interface blocks to meet the specific needs of the application.

The pressure frame unit consists of the pressure frame plate and pushrods.

Thanks to the modular design, it is possible to individually customise the functionality, test safety, and ease of use of the test fixtures and exchangeable kits with functional units.