SUCCESS-STORY

CRS uses identical needle bed for automated and manual contacting

CRS has developed an inline test station for PCBs that can be operated using the same exchangeable kits (ATS) used for manual test fixtures. This multiple use of a standard kits from INGUN offers end customers significant efficiency and cost advantages.

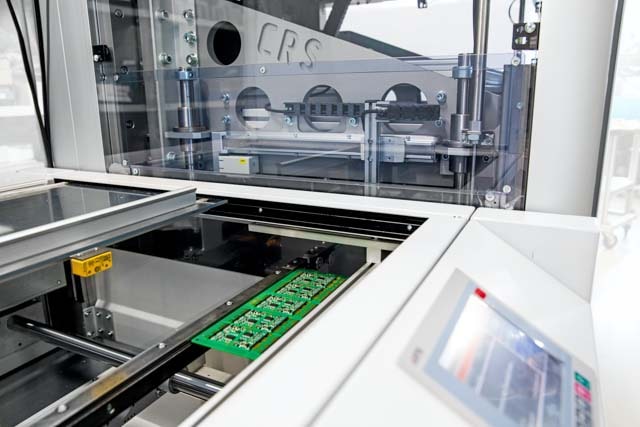

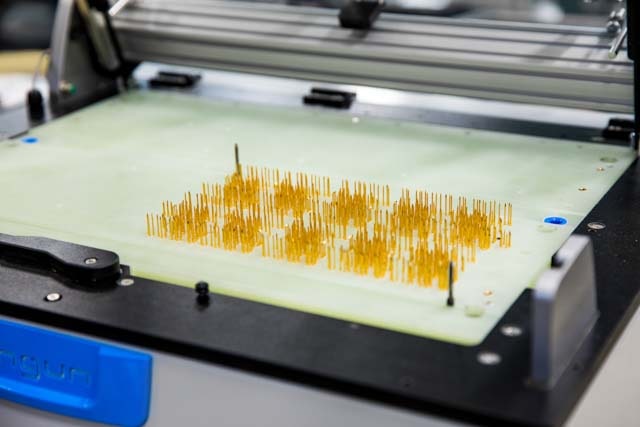

The company CRS Prüftechnik GmbH from Meersburg on the banks of Lake Constance has made a name for itself worldwide with test systems for automatic electrical circuit board testing: Test stations, specialised machinery, and marking systems in the areas of circuit board and power semiconductor testing are in use in many countries and industries – ranging from automotive to medical and energy technology to consumer electronics. Following feedback from customers, CRS has established a new system for PCB testing in recent years, which enables a particularly efficient use of standard test fixtures and exchangeable kits. The CRS system uses the ATS MA12, ATS MA13, and ATS MA14 kits from INGUN for the two test stations IPS19 and Smart-Inline, which are also used in manual test fixtures in the MA21xx series.

With the new concept, CRS and INGUN cover the complete life cycle of a PCB with only one ex-changeable kit: Customers can test pre-series products with the same ATS which is later used in mass production in the inline system. After the end of the saturation phase, the exchangeable kit can be used again in the manual test fixture - a product change is carried out with a few simple steps. The customisation using suitable test probes and accessories from INGUN can be carried out inde-pendently by the end customer. Thanks to the cooperation between CRS and INGUN, customers receive an attractive comprehensive package from one source which combines the advantages of the manual test fixture with those of fully automatic testing. Due to the efficiency achieved and cost ad-vantages, the automation of the test fixture also becomes interesting for customers who have so far refrained from using it due to small production batches or a high number of PCB versions.