AUTOMOTIVE / CONNECTOR CONTACTING

The automotive industry is undergoing a profound transformation thanks to innovative technologies such as driver assistance systems and autonomous driving. Single Pair Ethernet (SPE) plays a key role in this development. This technology offers an efficient and cost-effective solution for the growing demands of vehicle networking.

SPE – Efficiency thanks to fewer cables

SPE is a network technology that uses only a single pair of conductors for data transmission - in contrast to the four pairs of conductors used in traditional Ethernet. This reduces the need for copper, conserves resources, and saves costs as well as weight and space. These advantages are particularly relevant for the automotive industry, as the weight reduction saves fuel and energy and therefore increases the vehicles' mileage.

Powerful data transmission

SPE enables data transmission at speeds of up to 1 Gbps and can reach frequencies of up to 2.5 GHz. This high performance makes SPE particularly suitable for applications that require time-critical data transmission. In the automotive sector, these are primarily advanced driver assistance systems (ADAS) and autonomous driving. Low latency and reliable data transmission are crucial for these applications.

With SPE, an IP-based network can be set up within the vehicle to ensure efficient communication between various systems and sensors. This helps to improve response times and the overall performance of vehicle systems.

Robust, reliable connectors

Depending on the application, both shielded and unshielded connector systems are available for implementing the SPE in vehicles. In the automotive industry, mechanically robust connectors such as H-MTD, MTD and MATEnet are particularly suitable. These connectors have been specially developed for the demanding conditions in vehicles

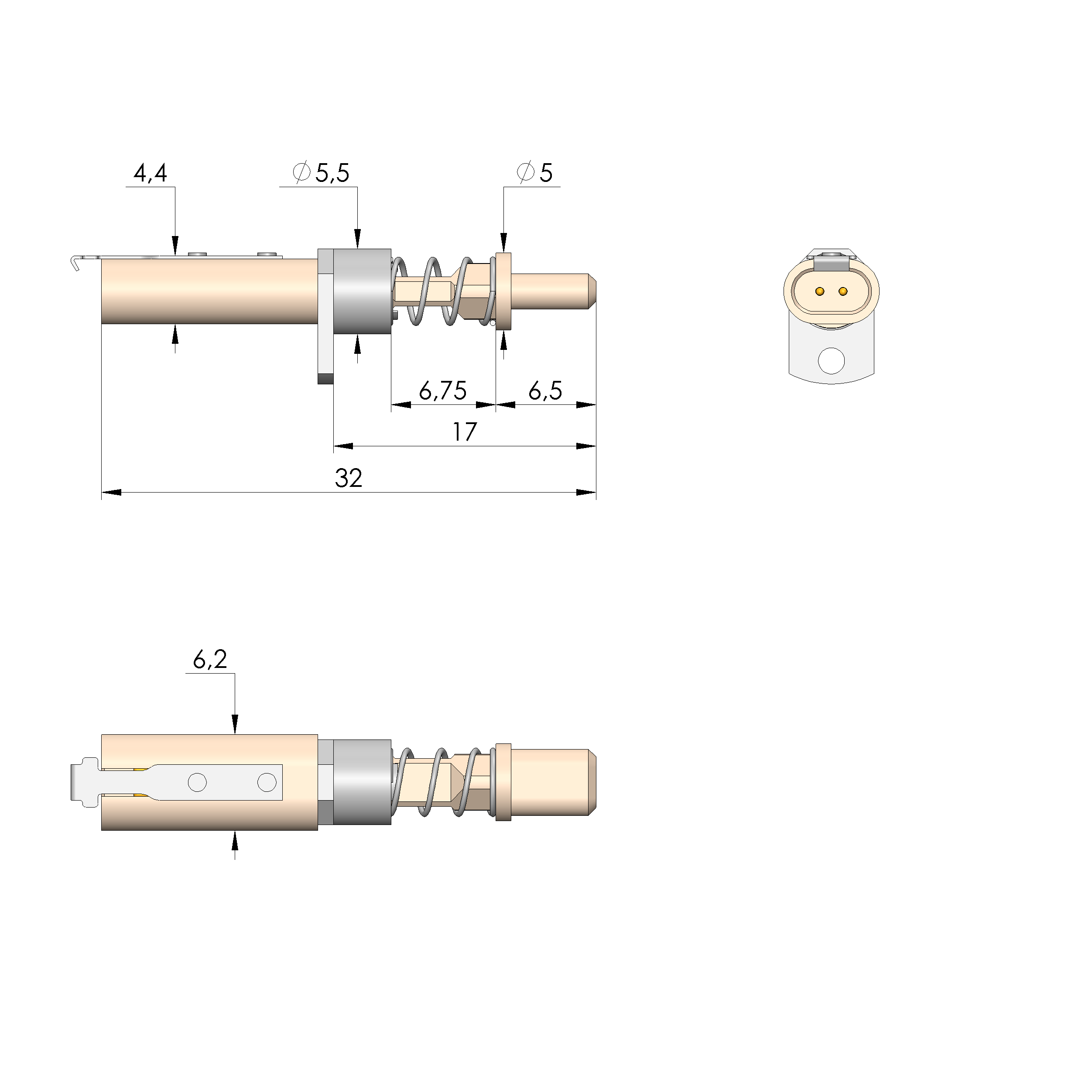

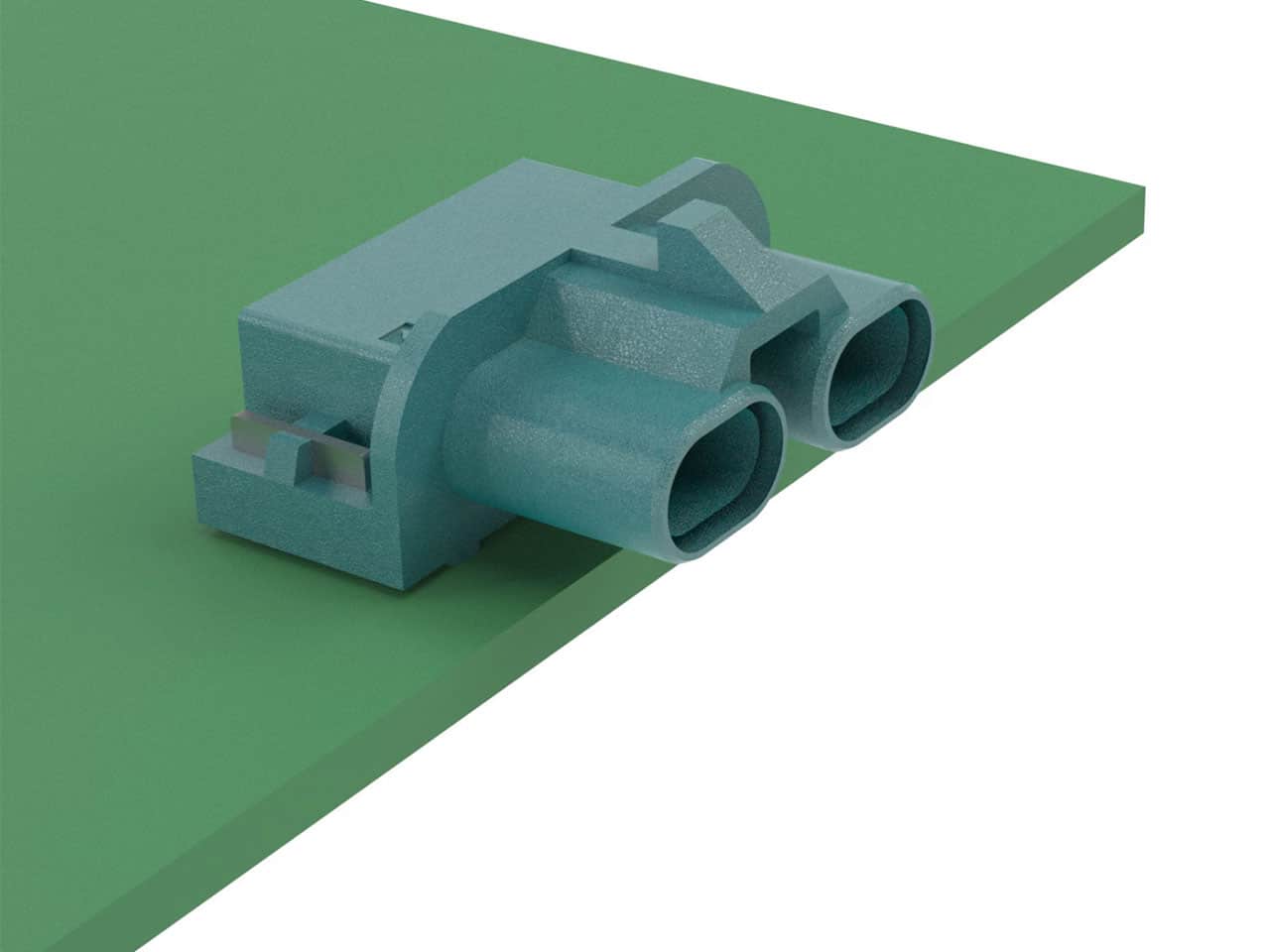

MTD: Single Pair Ethernet connector for automotive applications

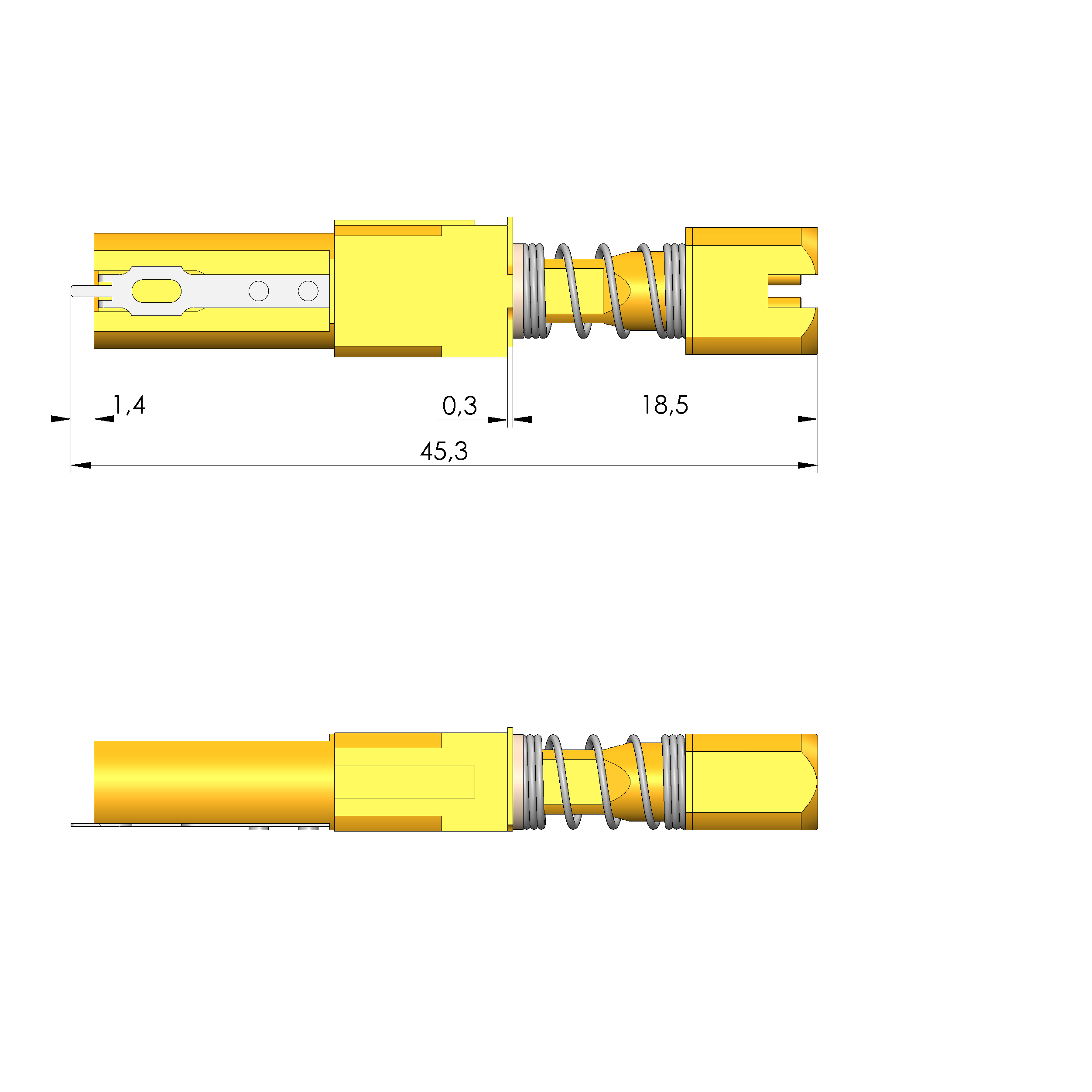

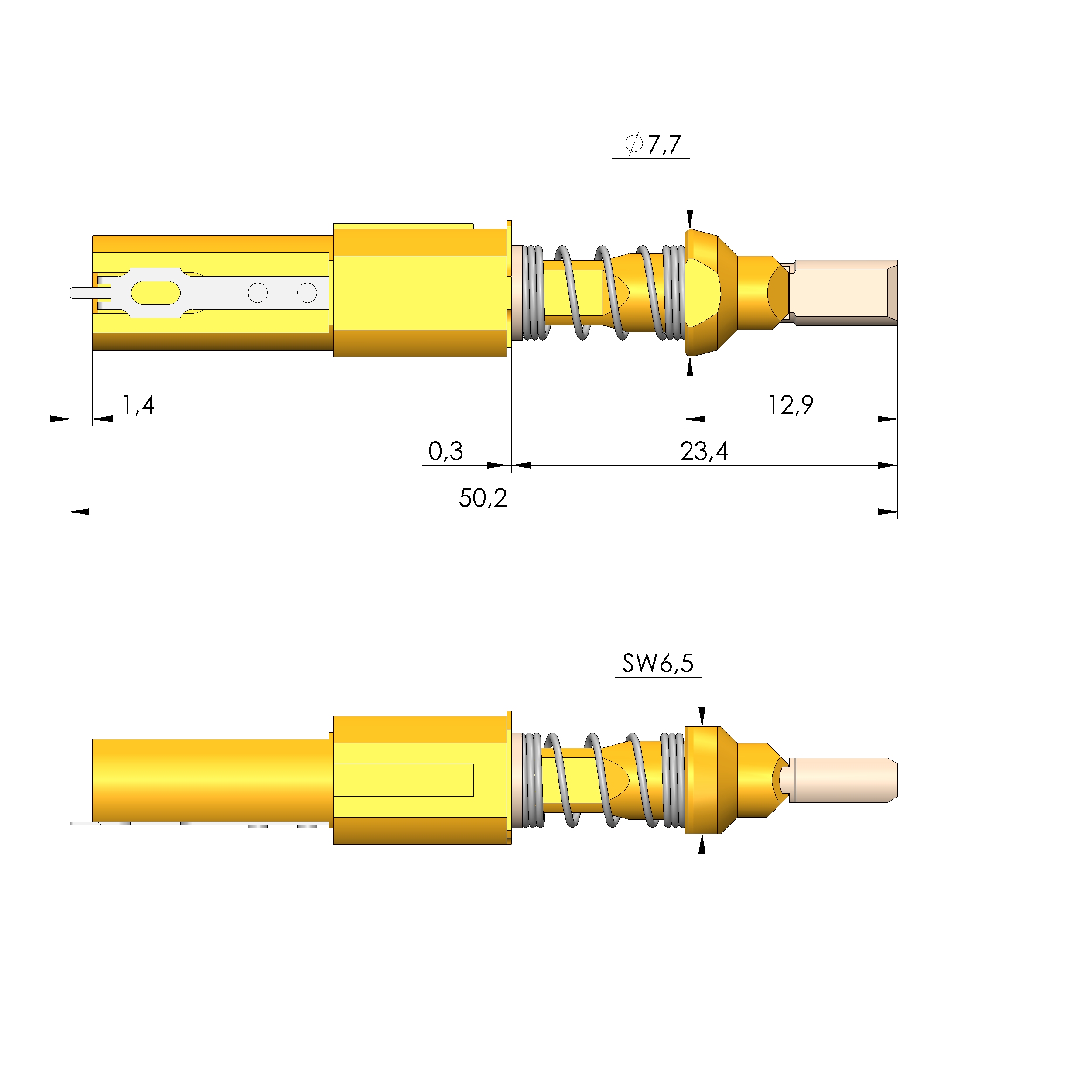

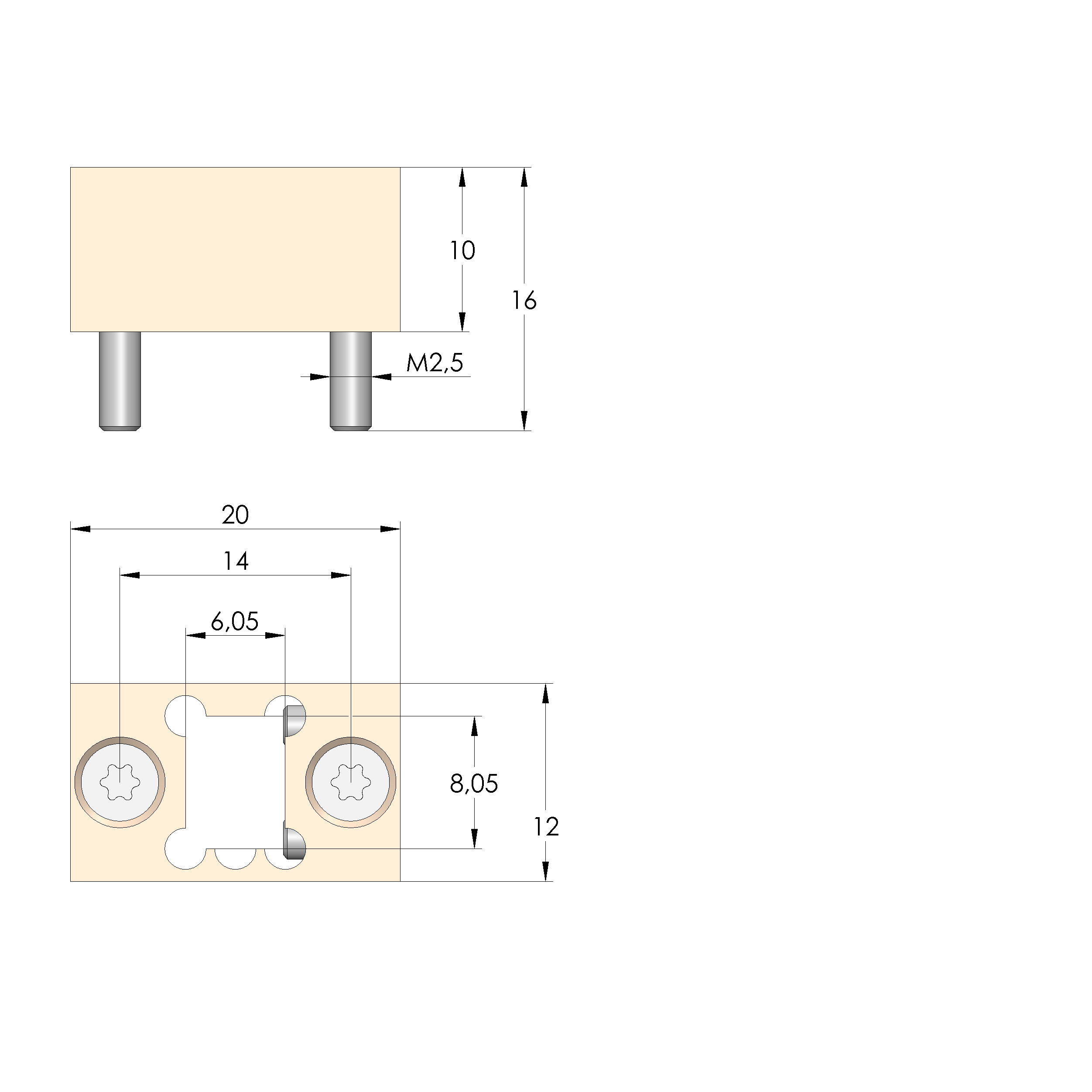

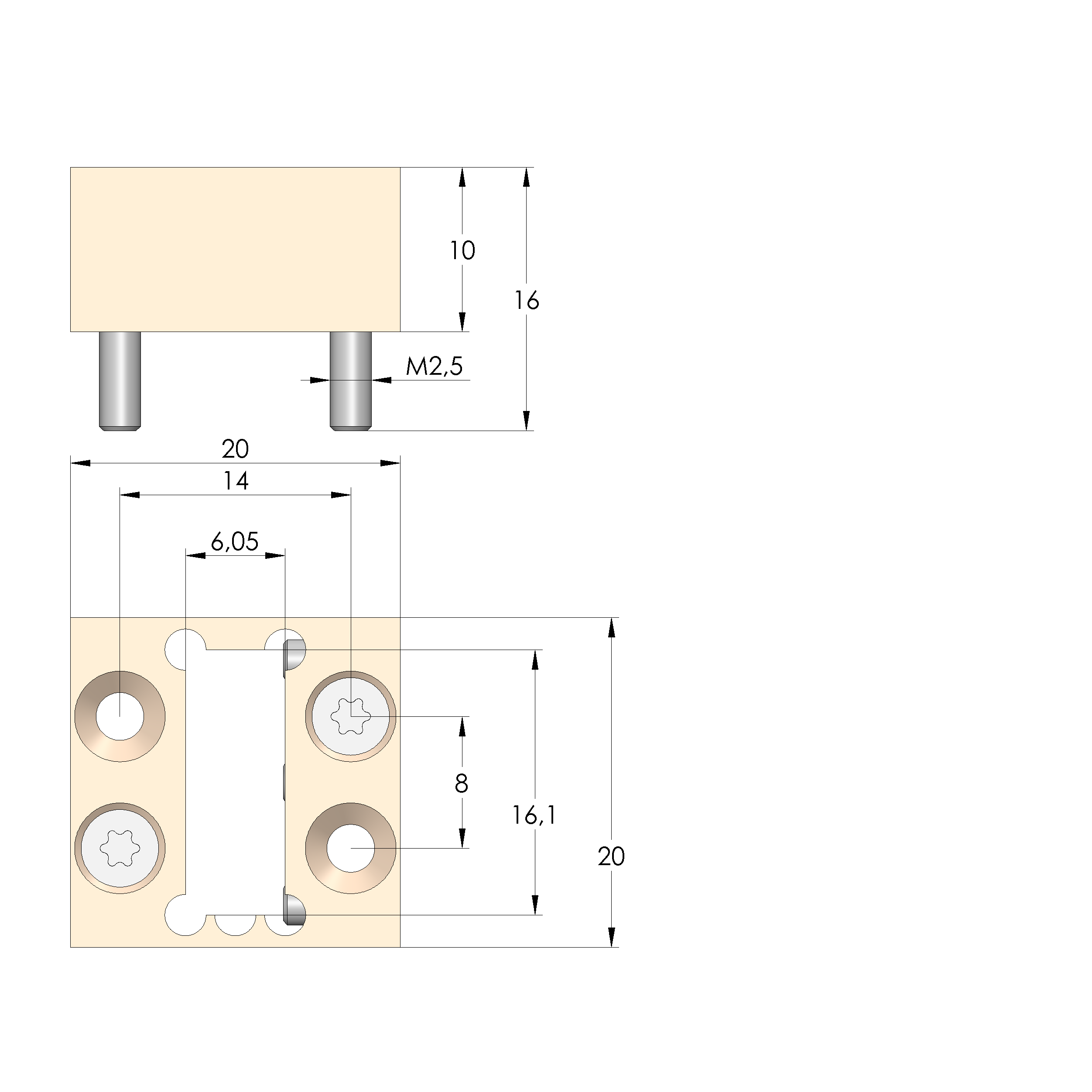

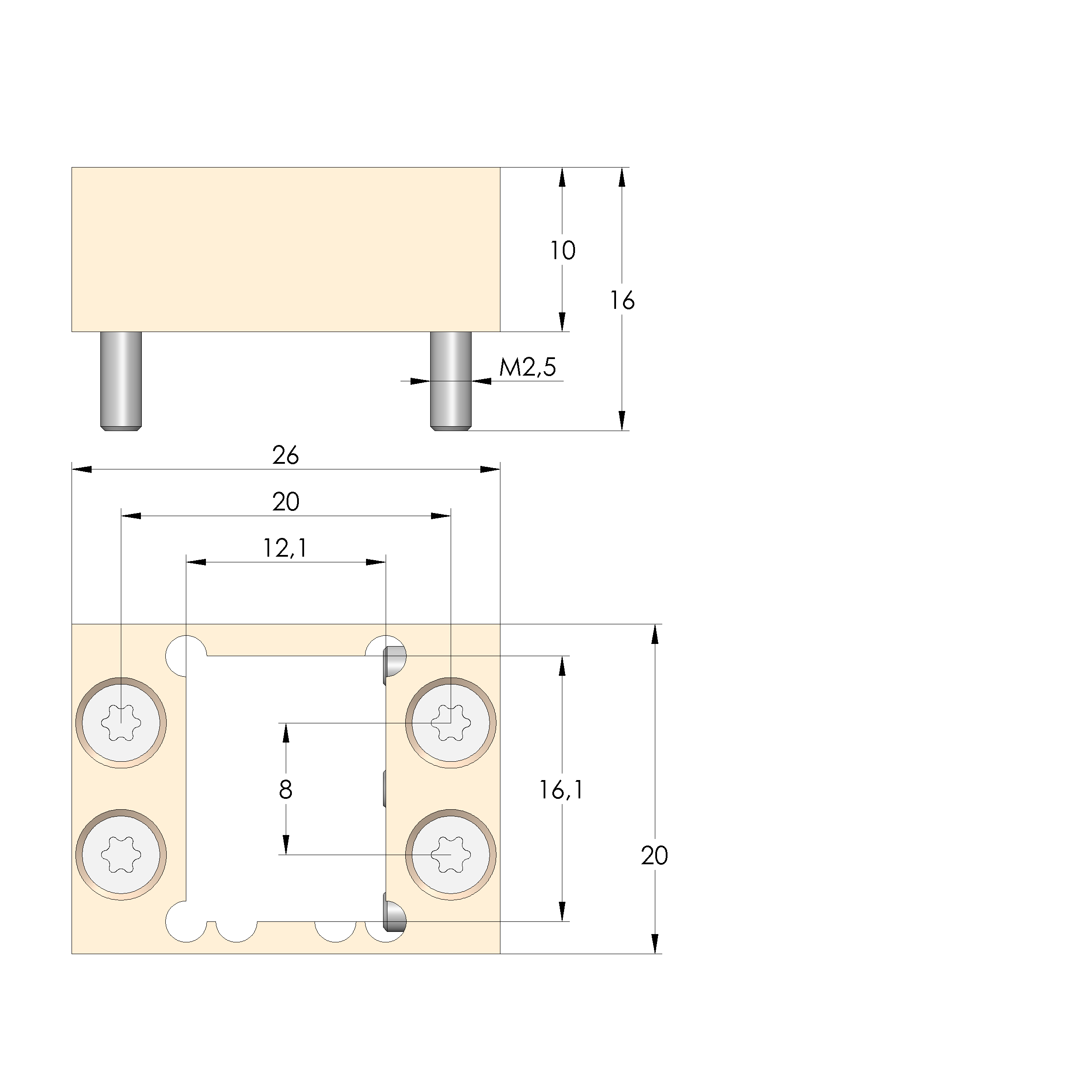

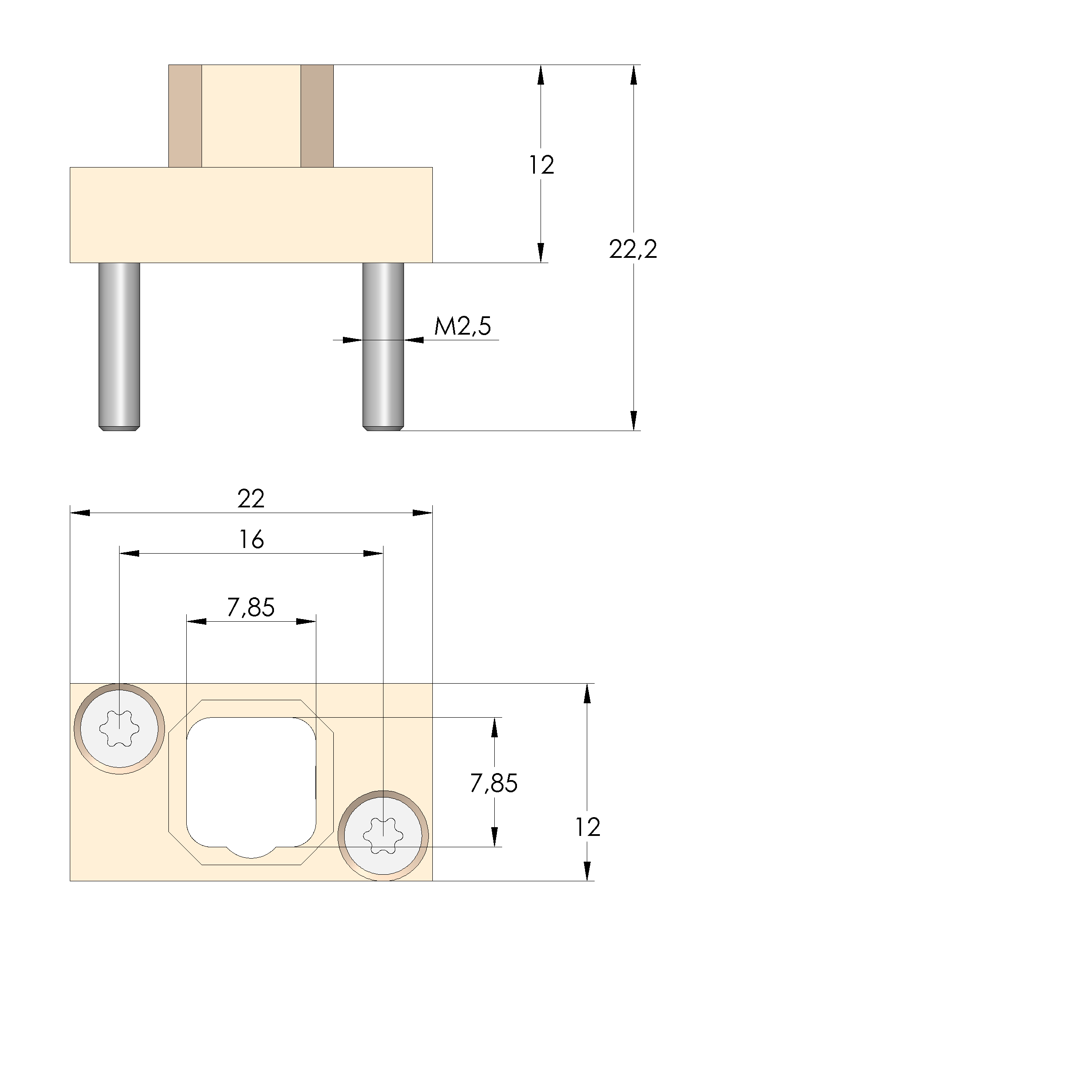

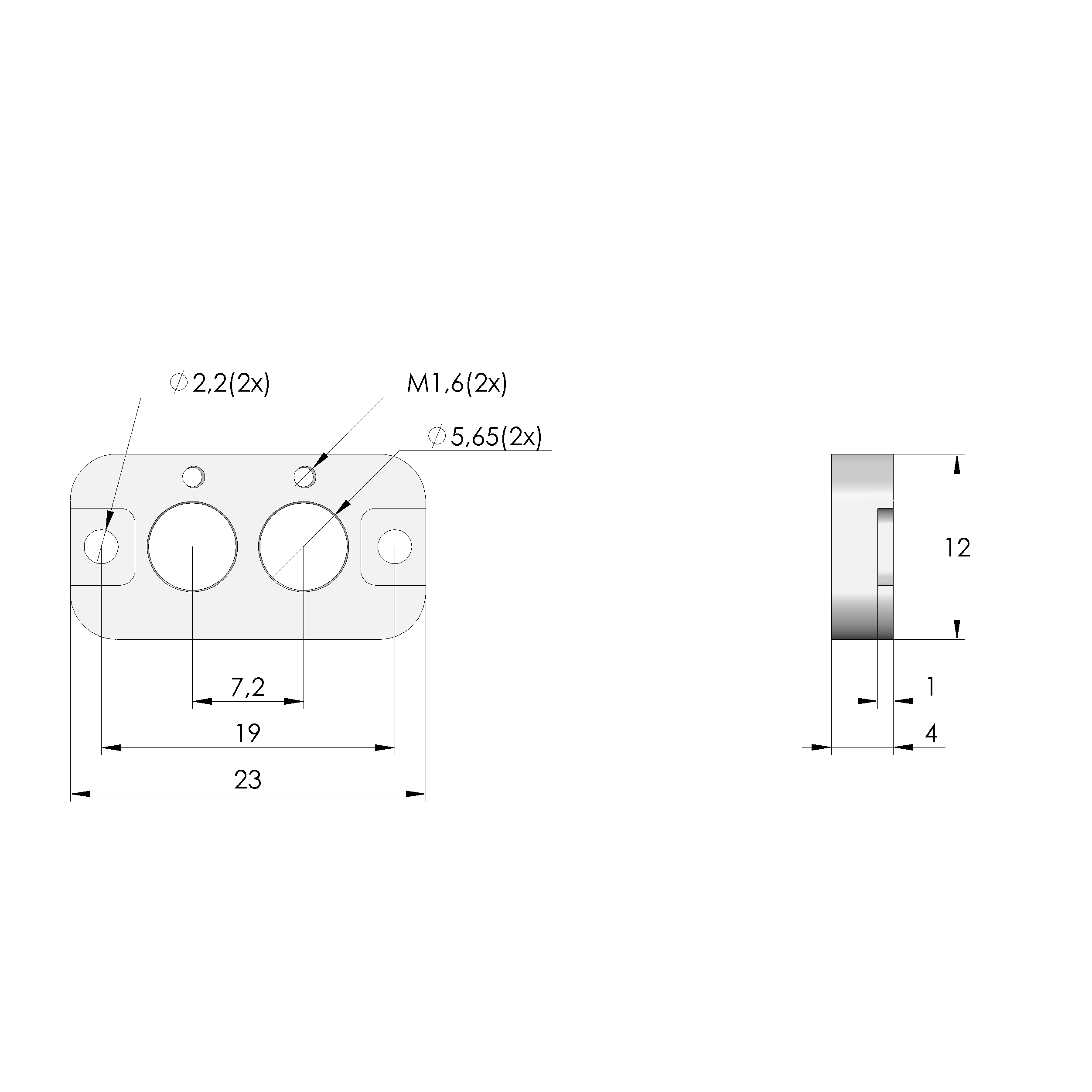

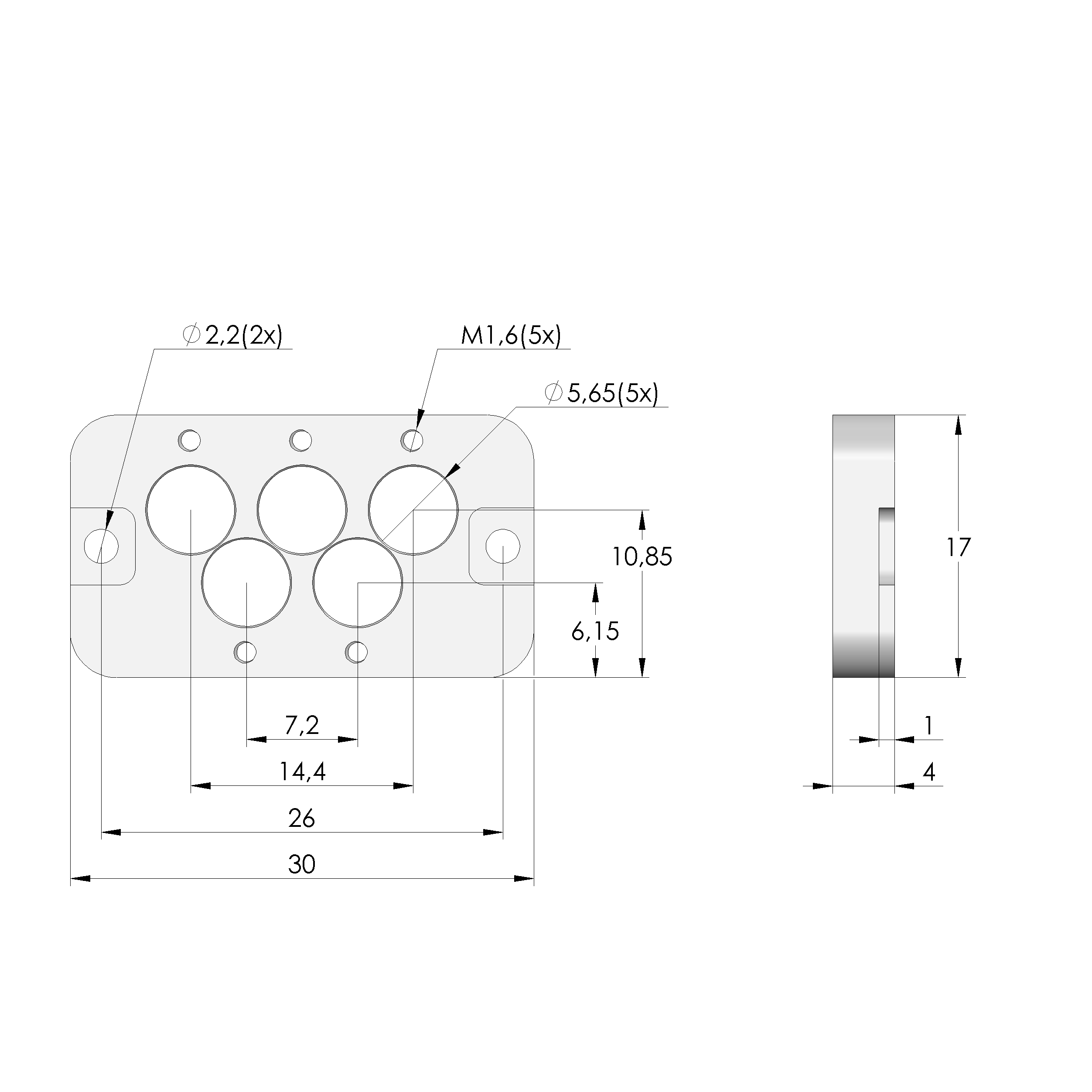

INGUN’s HFS-804 306 090 A 5442 MTD, contacting solution for MTD connectors

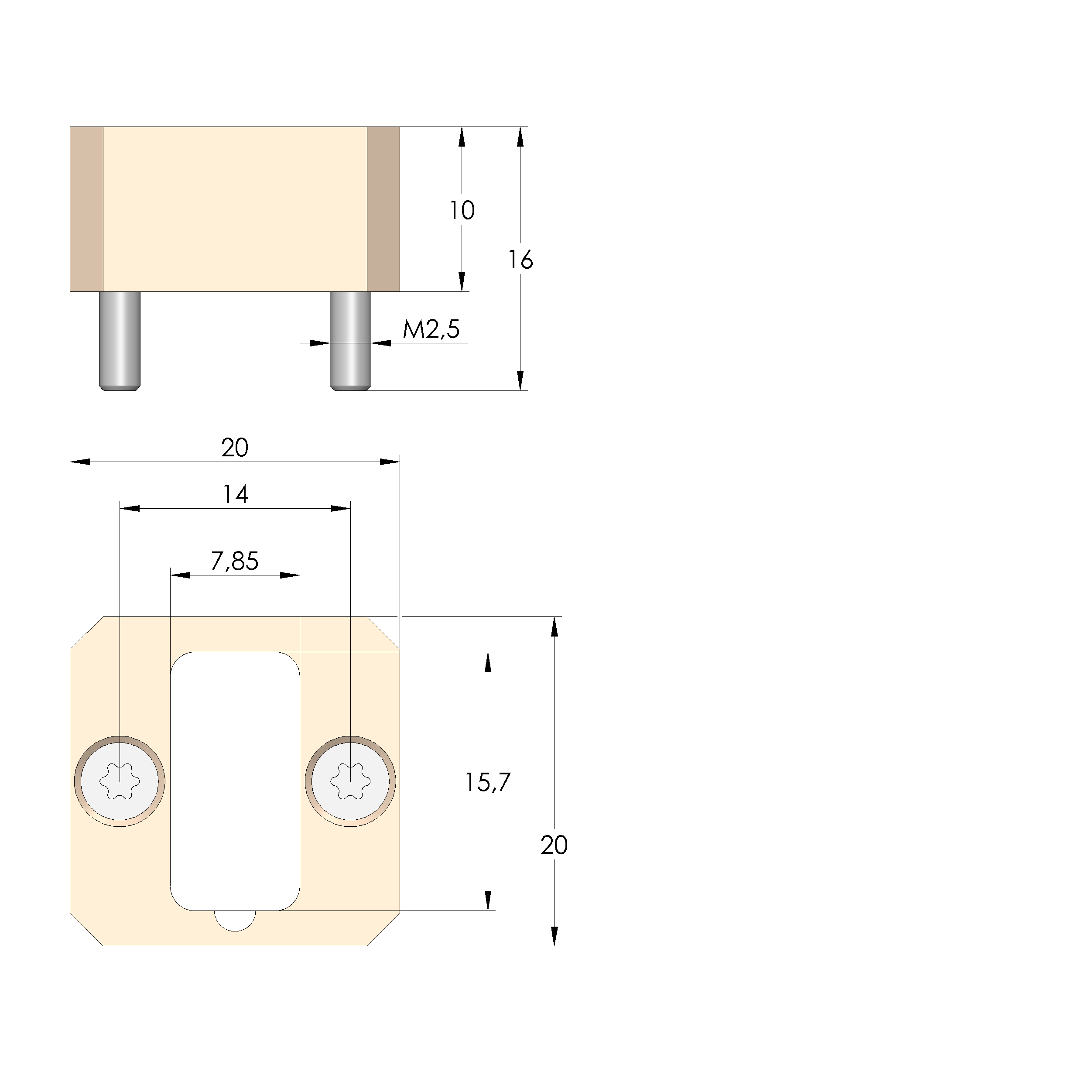

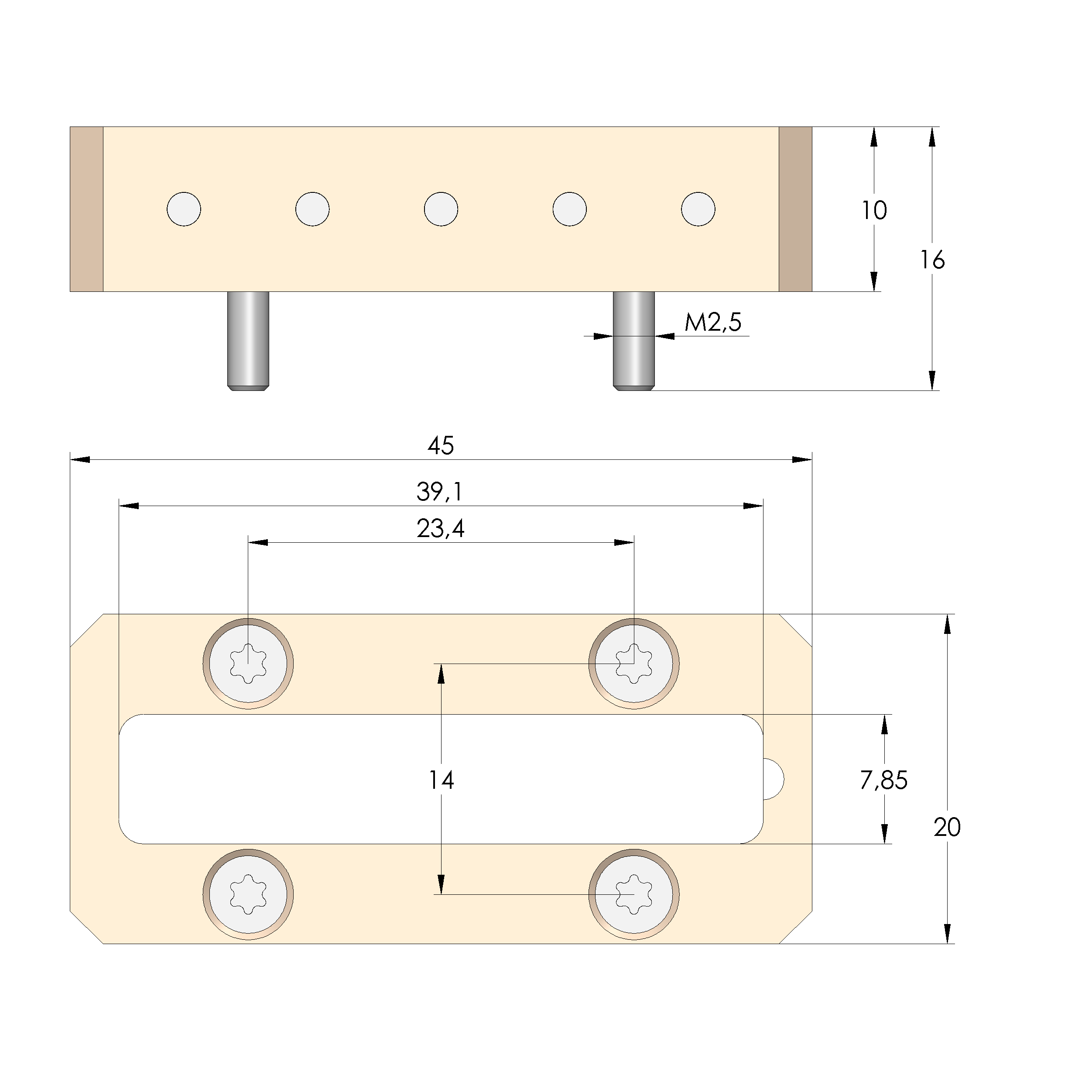

Our HFS-802 and HFS-804 series are specially designed for SPE connectors. These contacting solutions are characterised by their mechanical durability and can withstand even the harshest production environments. The integrated floating mechanism compensates for connector position tolerances, which increases reliability during testing.

In addition, we offer optional mounting brackets - KS-802 and KA-804 - which enable contacting for single connectors or configurations with multiple electrical contacts. This combination of integrated floating mechanism and mounting frame means these are much easier to use in test fixtures and automated test systems.

An impedance-controlled, fully-shielded design ensures interference-free data transmission even at high data rates, further increasing the reliability and performance of networks.

SPE – The future of networking

In addition to the automotive sector, SPE also has a wide range of applications in industry. It enables the seamless integration of sensors, actuators, and control devices into a homogeneous network, which is crucial for the implementation of Industry 4.0. The reduced wiring requirements reduce installation and maintenance costs, as well as improving reliability in harsh industrial environments.

SPE is a pioneering technology: it not only enables the development of advanced driver assistance systems and autonomous vehicles, but also supports the networking of smart factories. SPE provides a solution that combines cost efficiency, performance, and resource conservation – meaning it plays a key role in shaping the future of networking. In the mid-term, SPE could replace traditional field bus systems in the automation of buildings, processes and factories to become the standard solution for a wide range of applications.

Want to find out more about technologies, applications, and contacting solutions in the automotive industry? Then our free on-demand webinar is just right for you.

"Automotive 5G: Experience the board net data highway without speed limits".