PRODUCTS

Batteries are the storage medium for electrical energy in stationary and mobile applications which provide an emission-free energy supply. However, the manufacturing process is complex and energy-intensive.

For this reason INGUN develops contacting solutions which boast low contact resistances, maximum reduced power losses, as well as stable, durable electrical connections in either single or multi-head contacting configurations.

Modular, scalable battery contacting solutions

Accumulators are available in various cell geometries and a variety of capacities for the most diverse test applications and requirements. Both capacities and voltages can be scaled modularly thanks to series and parallel connection. This means that electrical performance can be realised in line with requirements in terms of the power supply voltage and the capacities required. Important examples of this are applications in e-mobility, where a power supply which can deal with intermittent peaks in is necessary.

Versatile applications in battery manufacturing

The processes in battery manufacturing are diverse and characterised by a variety of challenges. For example, our products are used in the areas of formation, cell recycling, end-of-line (EoL) as well as the actual charging and discharging process, as well as OCV, SOC, and AC/DC-IR. Here, current flows of up to 800 Amps occur due to the partially high capacities of the accumulators. INGUN offers suitable solutions for a stable, loss-free contacting on cell, module, and pack level. The approach to scalability as well as modularity of test solutions is very much in focus. Various test probes with a selection of tip styles and technical features can be used and exchanged easily during the testing process.

Modularity and scalability in high current ranges for maximum customer benefit

The approach of modularity as well as scalability allows our customers maximum flexibility in terms of their test set-up. Our multi-head solutions are suitable for high current ranges with various graduation options. Similarly, other parameters relevant for the testing process can optionally be tapped or controlled via the built-in sense contact, temperature sensor, and active cooling inside the probe and at the plunger tip.

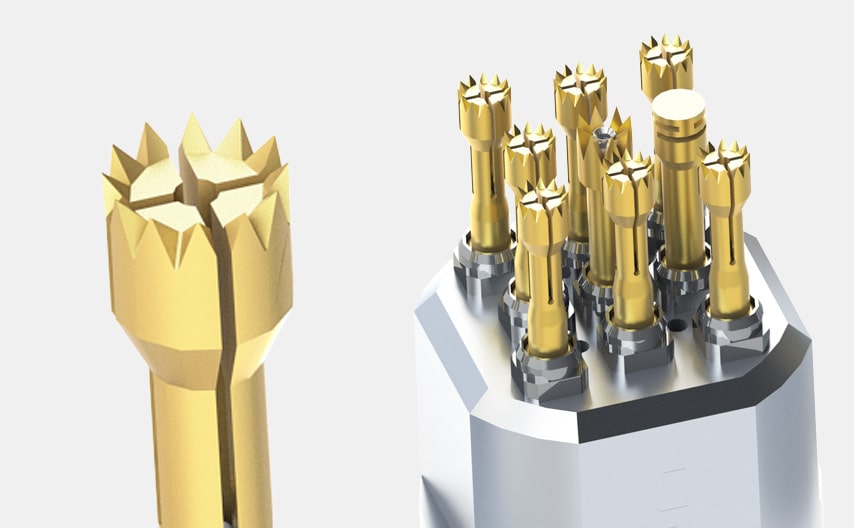

Multi-head configuration

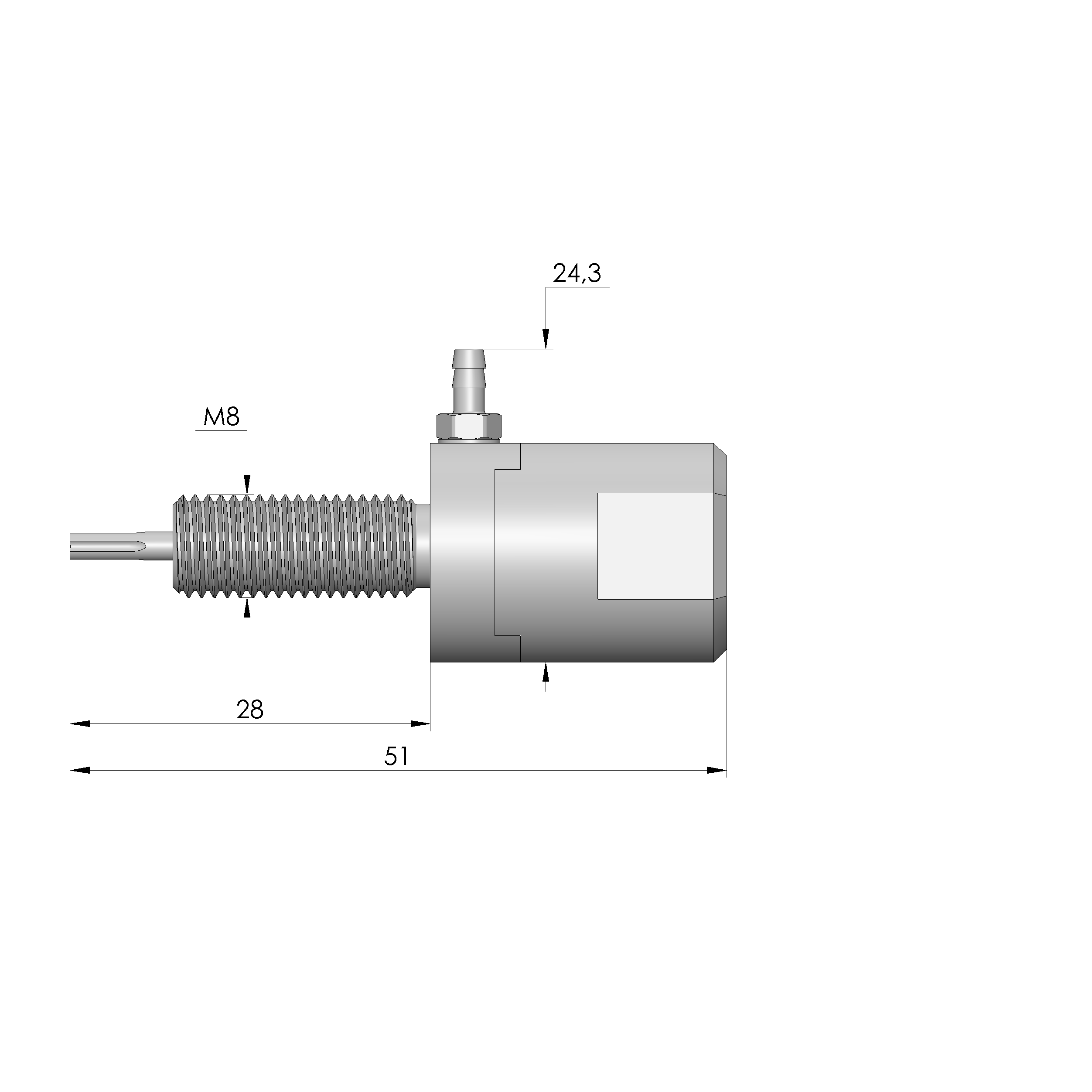

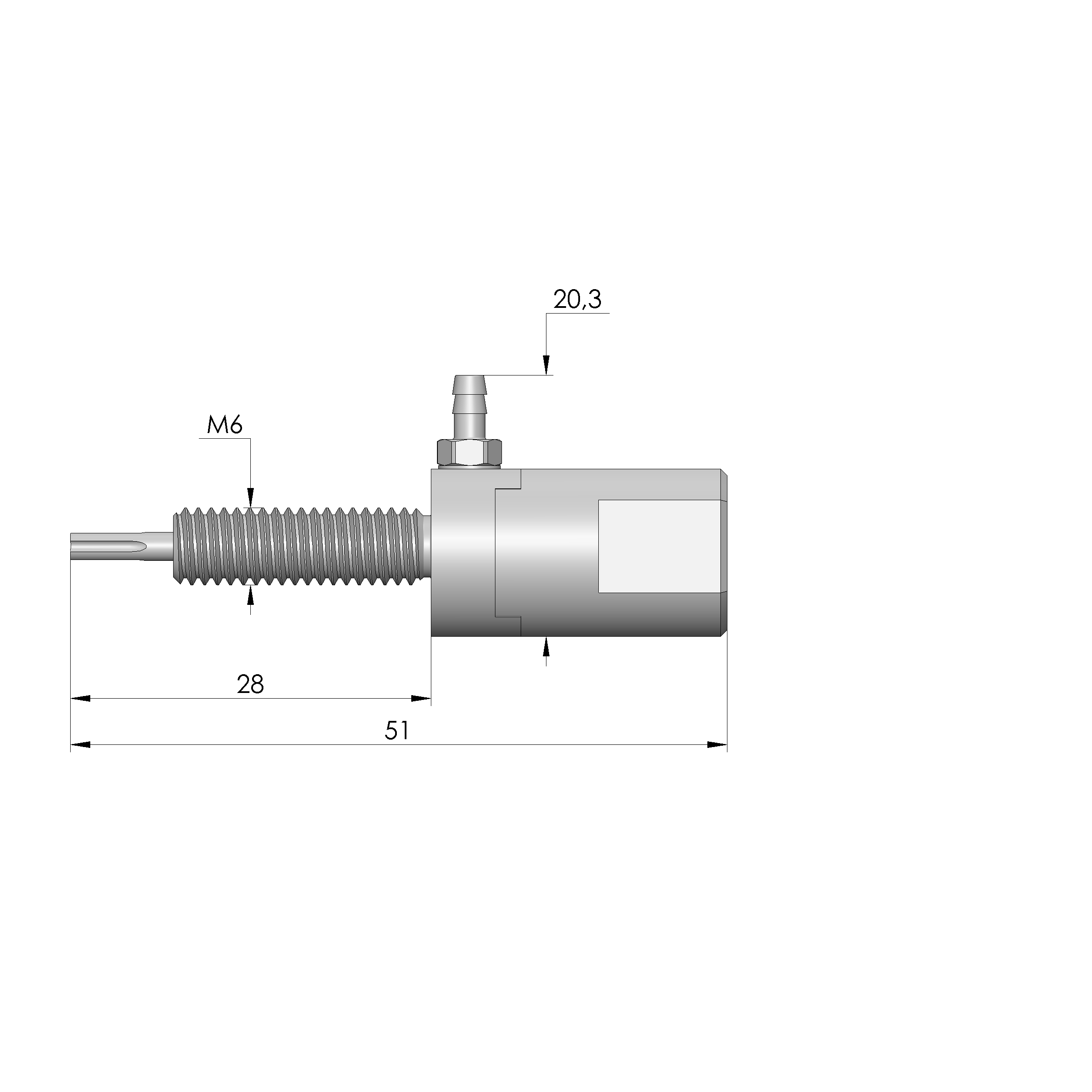

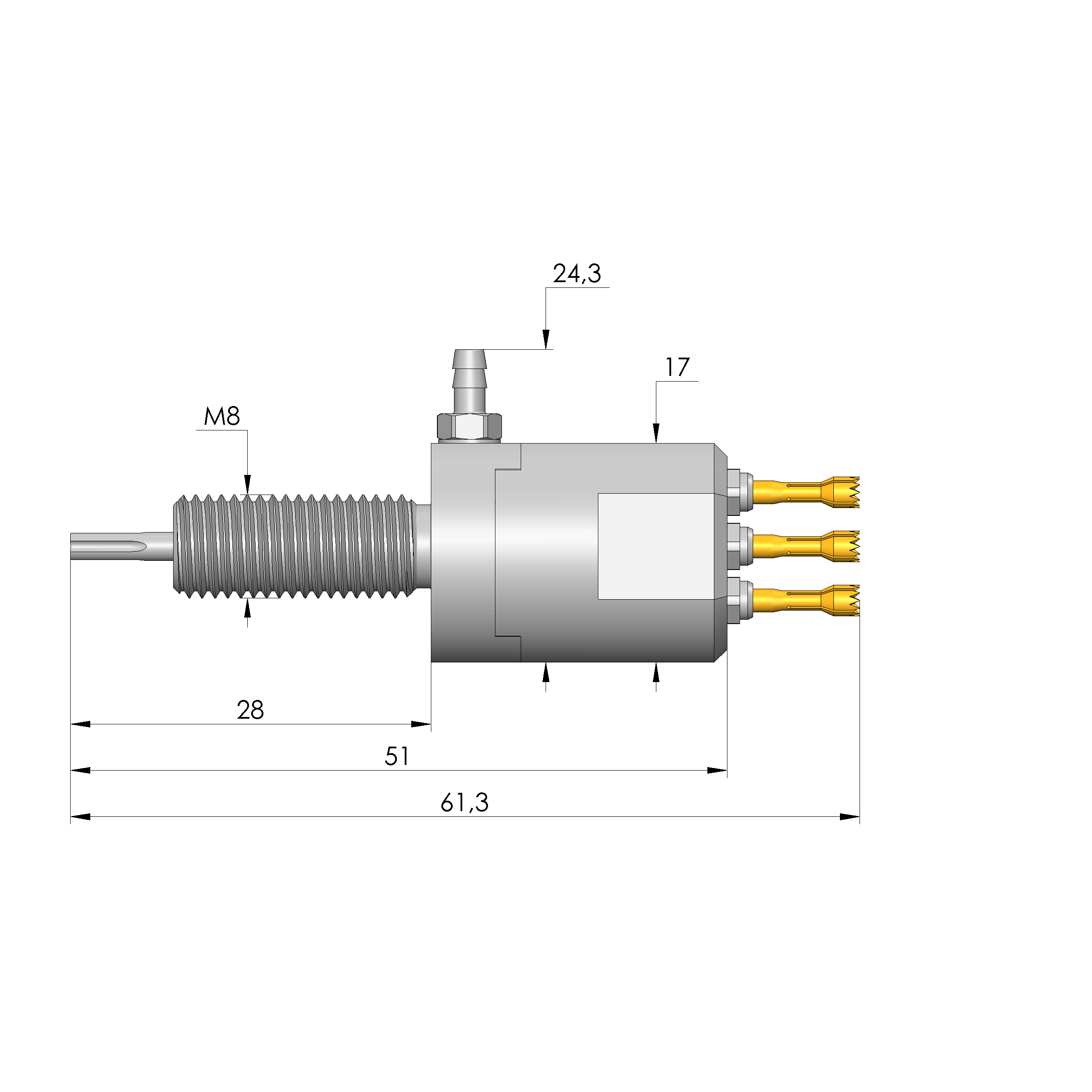

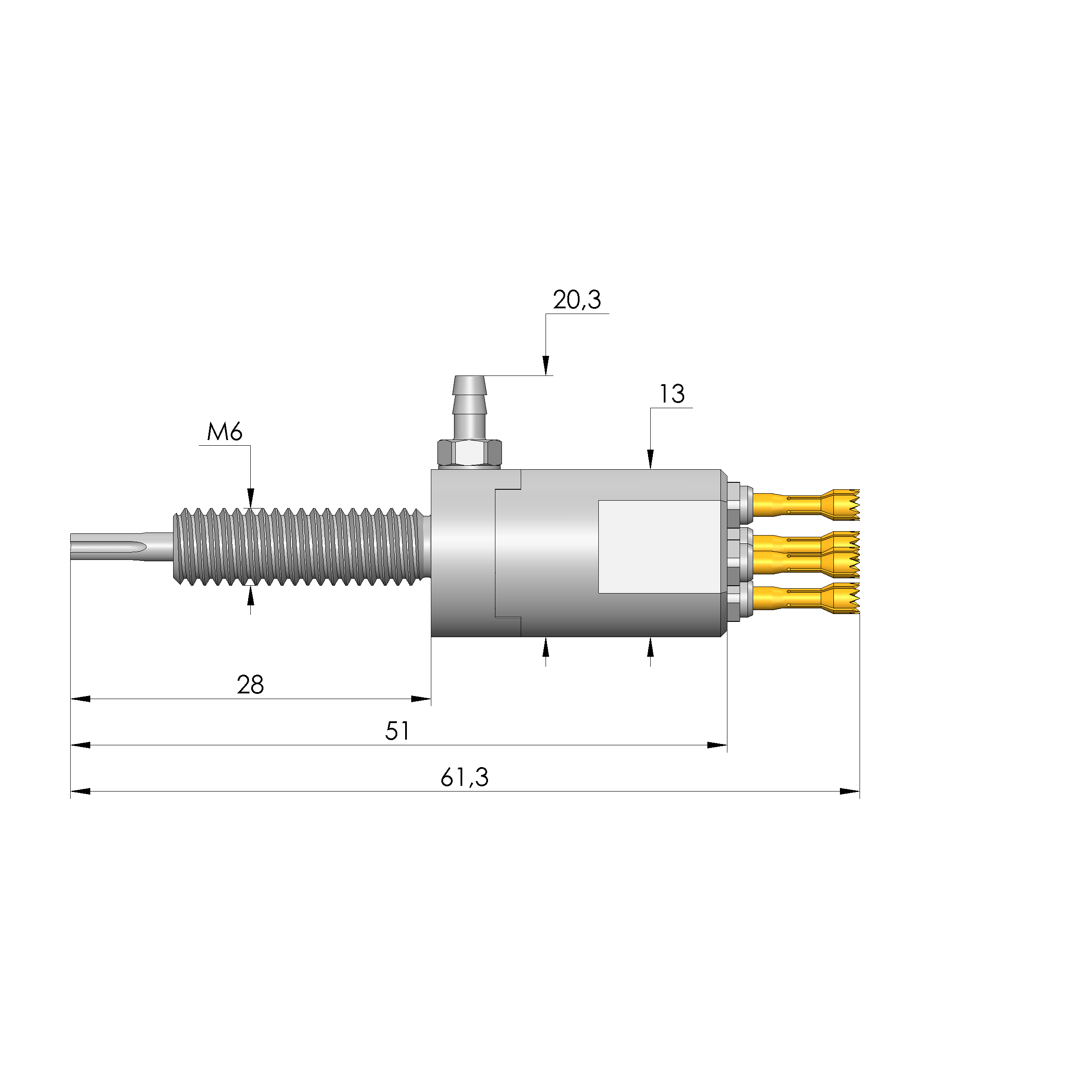

Configuring the best base body version

Customers can choose between two base body versions for the contacting solution, to hold either five or eight probes. The selection depends primarily on the test point or area to be contacted. Then, the number of probes and the most suitable plunger tip-styles can be selected. The flexibility lies in the lack of restrictions in terms of number of probes and their placement position in the base body. The threaded connection point allows the contacting solution to installed using a cable lug or directly in a busbar. The sense contact and the temperature sensor are connected centrally. The air cooling is connected via the lateral air supply, ensuring the easiest accessibility.

HSS-120 series inspires

Due to the modularity and scalability provided by the contacting solutions, thanks to the possibility of using probe with various tip styles and spring forces from the HSS-120 and HSS-667 series (which share the same outer dimensions), a wide variety of customer requirements can be satisfied. Likewise, increasing current requirements can be met by using multiple test probes. The parallel connection of probes also reduces the total resistance and thus the resulting power loss. Silver rivet caps and tip styles with protective caps can also be used to insulate the test probes from each other.

Energy-saving contacting of oxidised surfaces

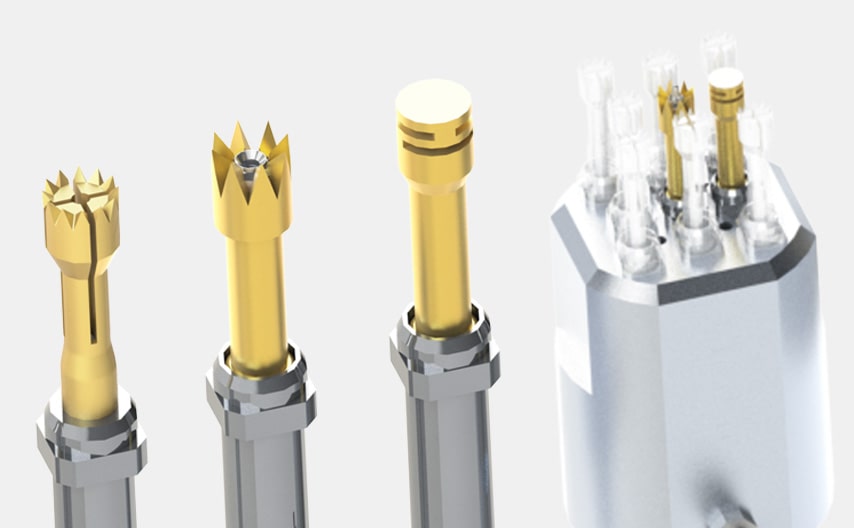

Reduction of power losses using HSS-667 probes

The HSS-667 series was specially developed for battery contacts with oxide layers. These products make it possible to penetrate the hard oxide layer within the contact stroke by actively spreading the tip style. Due to the electrically non-conductive properties of the oxide layer, penetration of this layer is absolutely necessary. This is where conventional aggressive plunger tip-styles reach their limits in terms of being able to reduce contact resistance. These conventional solutions simply cannot reduce the resistance any further. The HSS-667 series now makes it possible to achieve lower levels of resistance, meaning that the power losses can be significantly reduced and the system-critical temperatures in the battery environment can also be minimised.

Measure voltage and temperature at the battery terminal while actively cooling

Optionally, the multi-head solutions can be equipped with a sense contact, a temperature sensor as well as air-cooling features. The sense contact is insulated and can be manufactured with the same geometries as the selected tip-style. If the sense contact including the temperature sensor is selected, a hybrid probe is used. The air cooling is always carried out via the housing and can be reinforced by using an air-cooling probe, which ensures an air flow at the contact points.