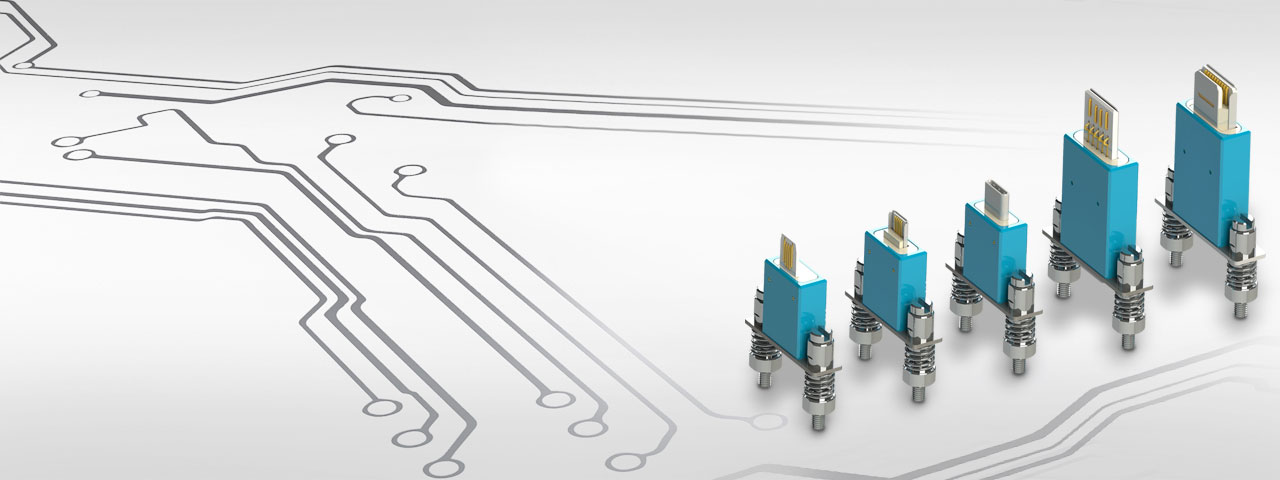

CONNECTOR CONTACTING

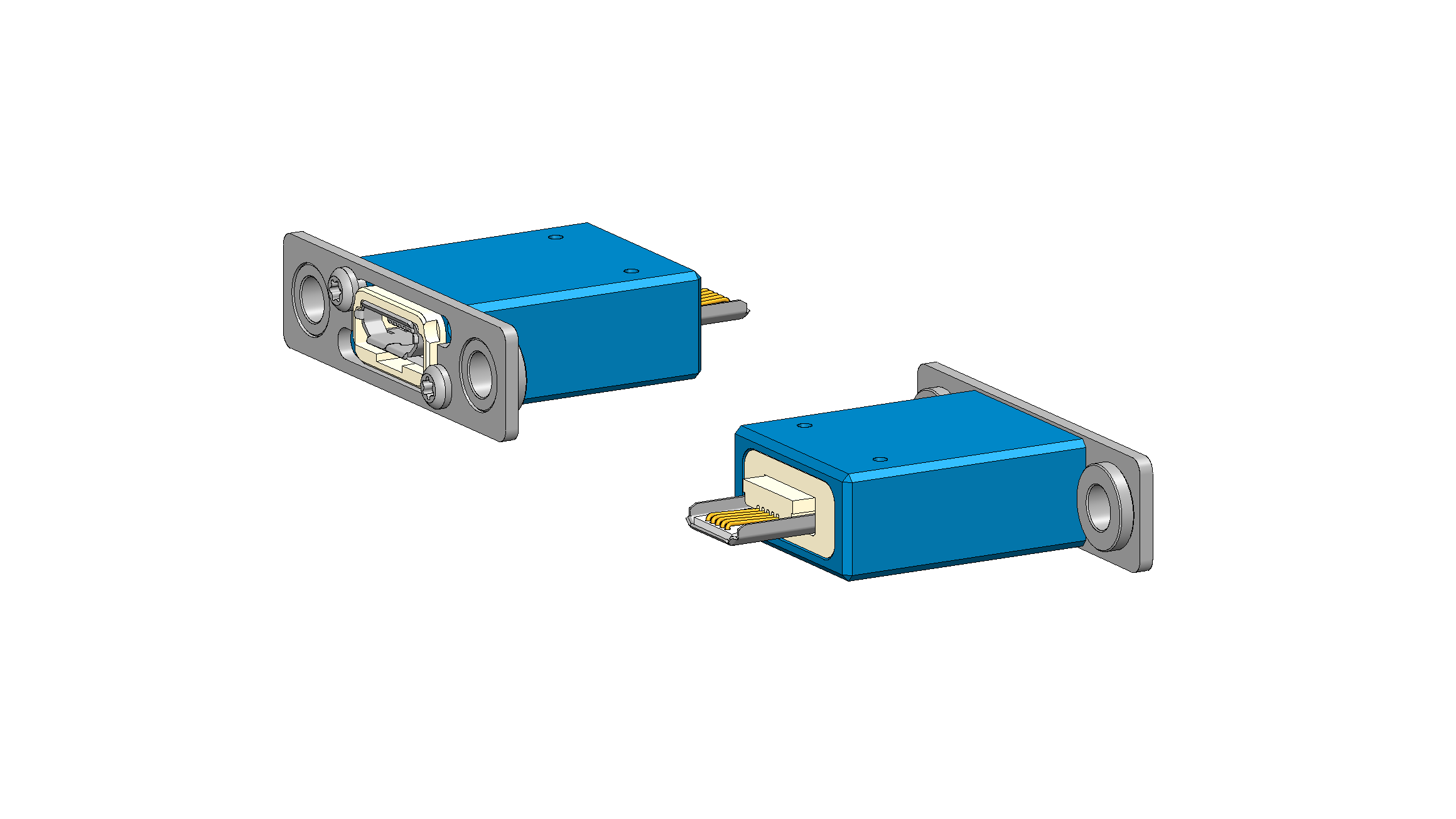

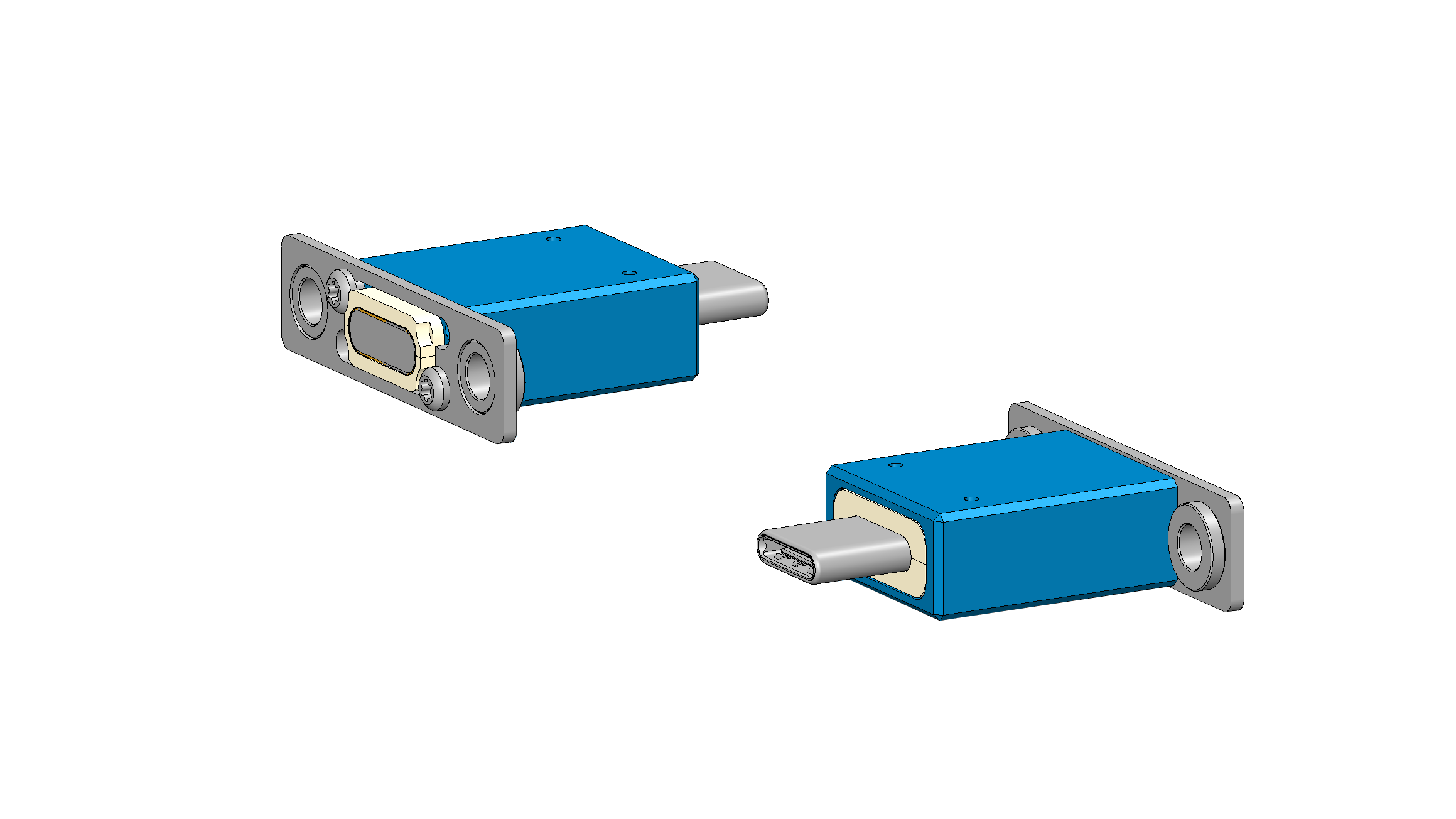

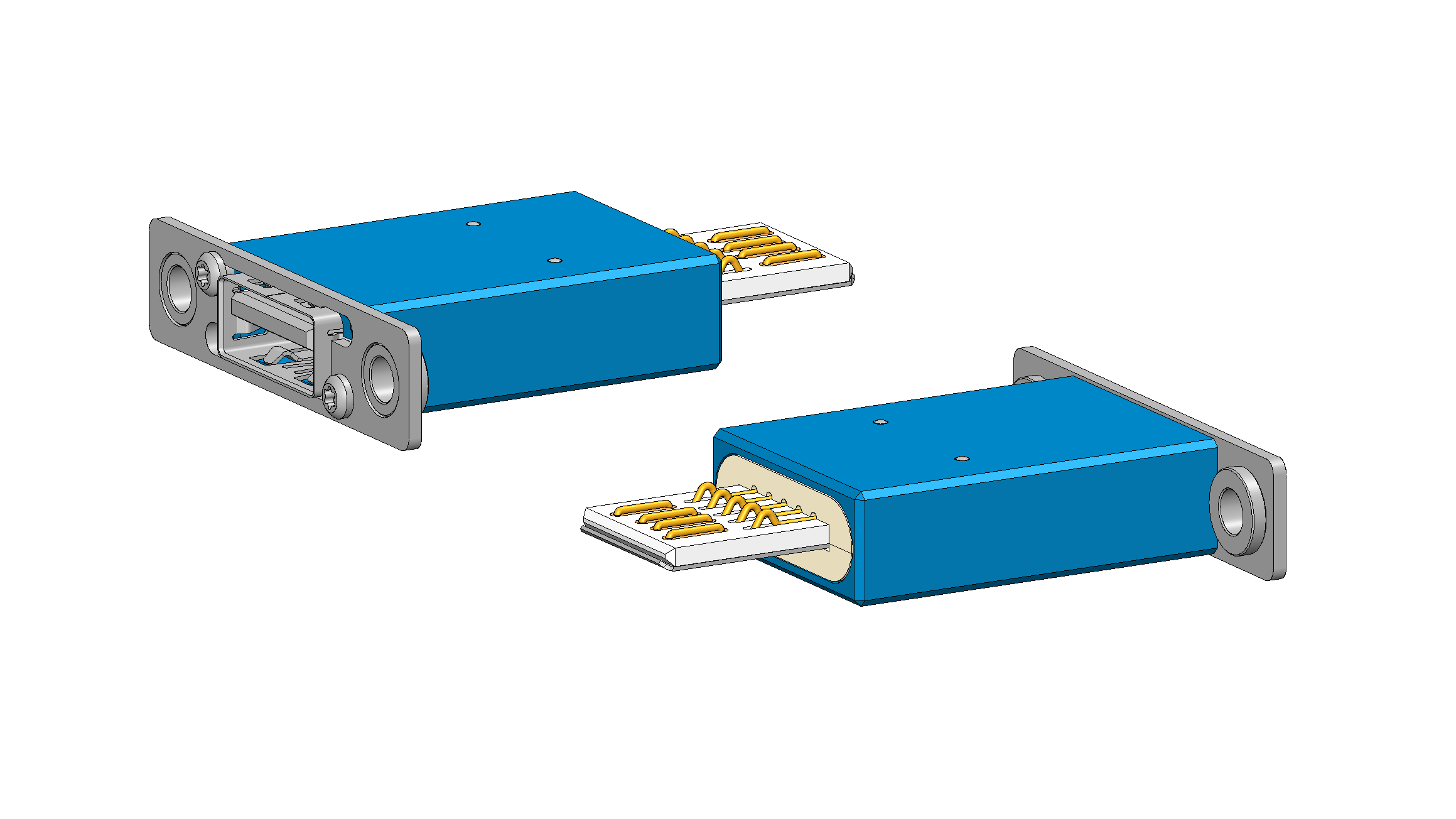

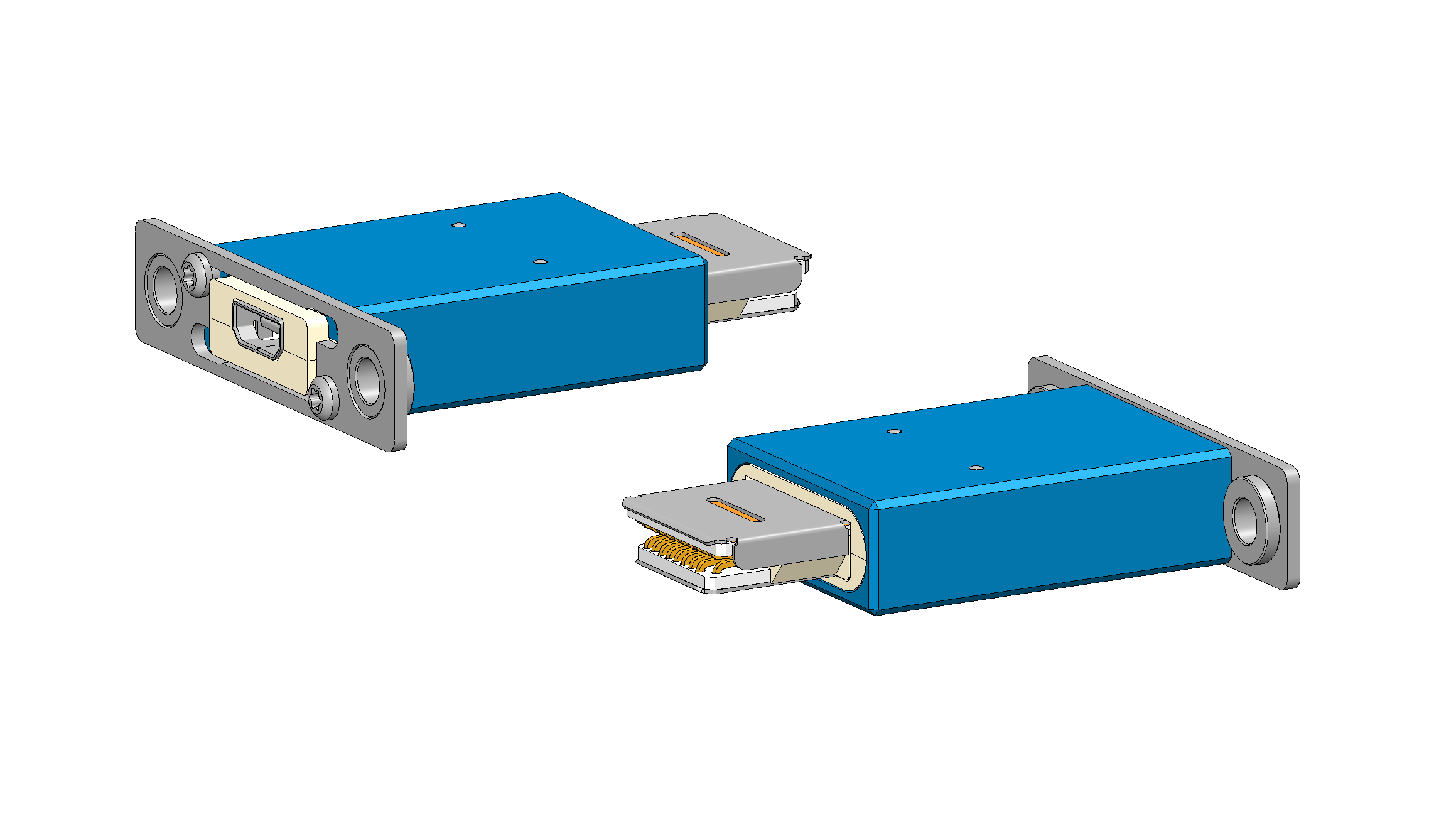

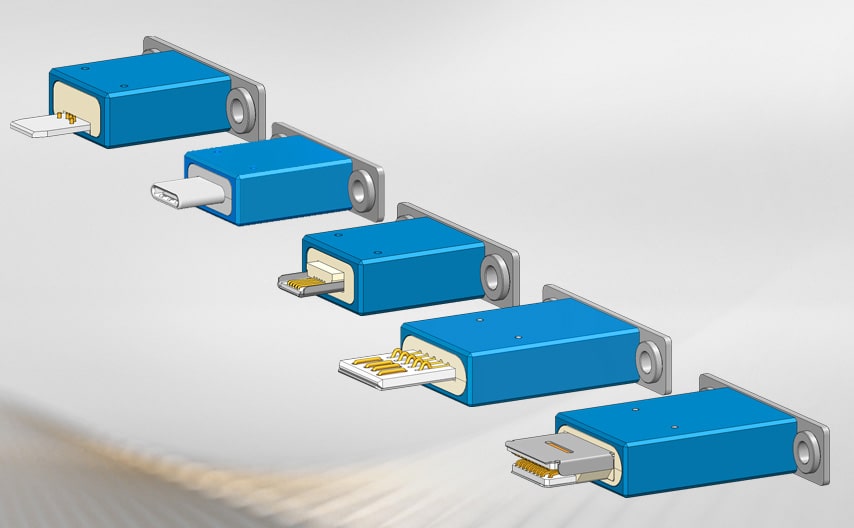

USB and HDMI connectors are used in various sectors such as electronics, telecommunications, and lately also increasingly in the automotive sector. USB3.0A and USB3.1C in particular are used for these applications.

Using the INGUN high-speed test plugs, data rates and flash speeds corresponding to the original connectors are possible. Original cables from the product family can be used as an interface to the test system.

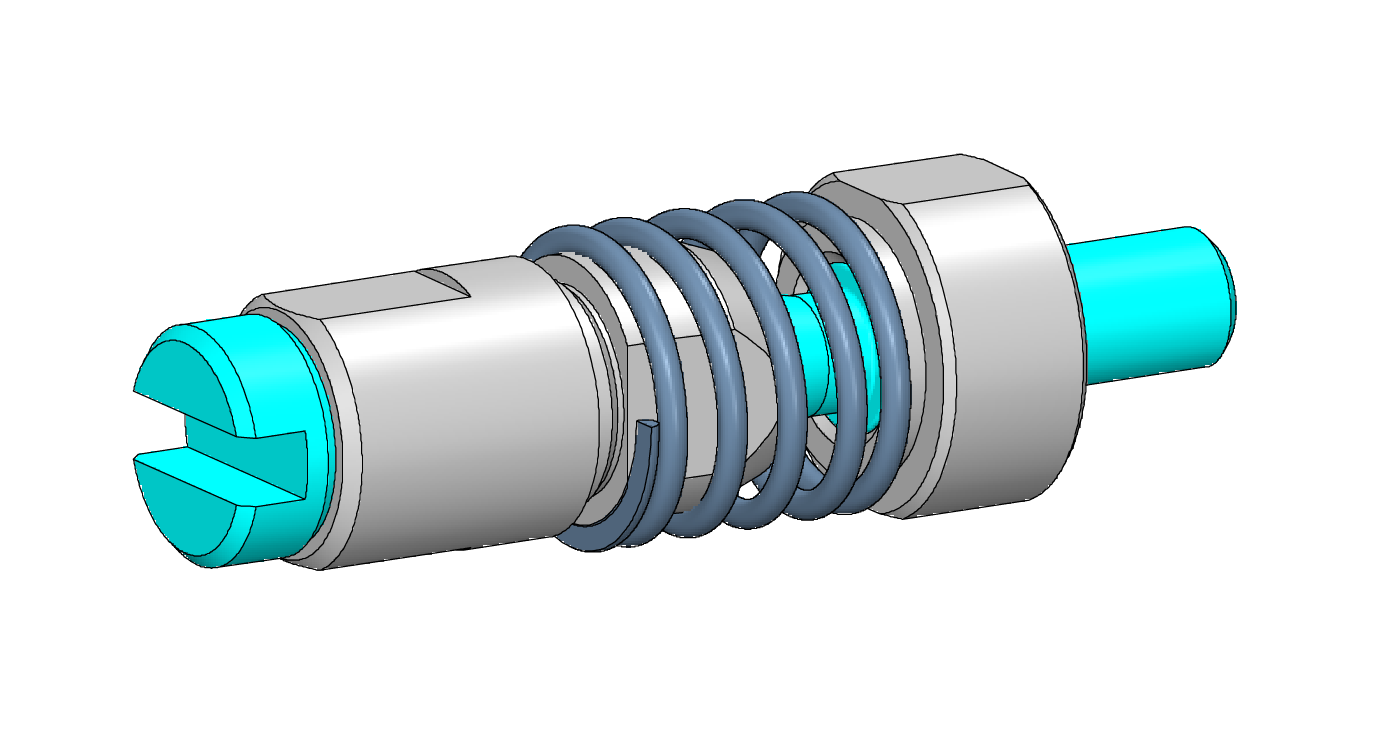

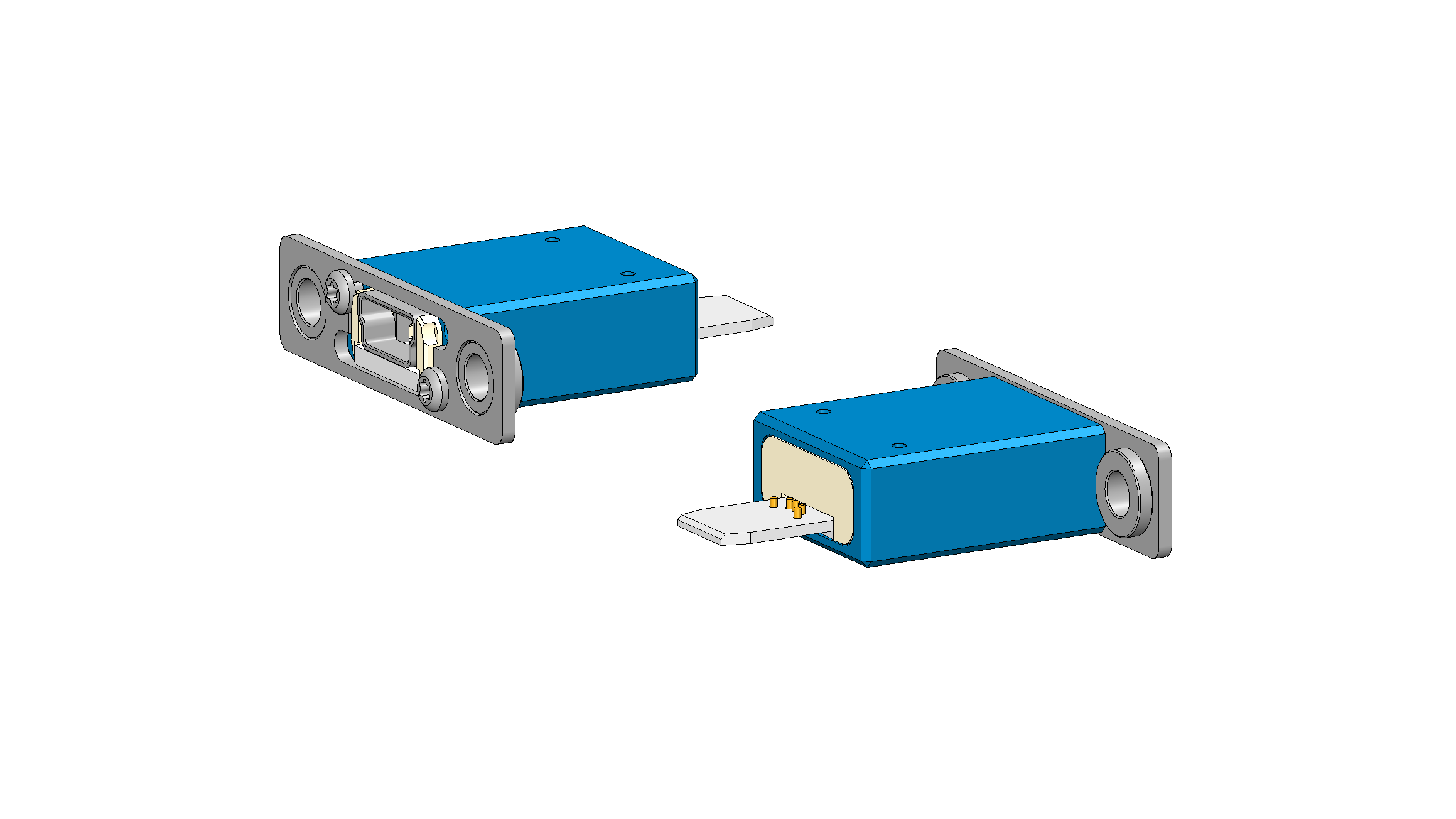

New design with increased mechanical load capacity

The focus of INGUN’s new test plug series for USB and HDMI connectors is on the increased mechanical load capacity - the entire test electronic hardware is now encased in extremely robust aluminium housing. In addition to surface protection, the blue anodised coating provides an optical accent in the test fixture and is in line with INGUN’s corporate branding.

Improved fine adjustment and longer service life

In the new series, the option to manually adjust the test plug’s alignment to the device under test has been optimised. The test plug can be adjusted ± 0.5 mm horizontally and ± 0.25 mm vertically to the DUT when installed. The test plug for USB3.0A has an additional protective plate on the contacting tab that significantly increases the service life.

The test plugs can be installed in various configurations: The test plugs can be mounted side by side and on top of each other with the two mounting brackets supplied or using four M1.6 screws directly in the test fixture. To create a floating mount for the test plugs, INGUN offers optional spring elements which can compensate tolerances of ± 0.4 mm as well as positioning inaccuracies when in contact with the DUT. These features compensate for mounting tolerances of PCB components and avoid side loads.

All features at a glance:

- Precise, low-wear contacting

- Outstanding service life

- Reliable data transmission

- Floating assembly

- Signal transmission via original connector plug