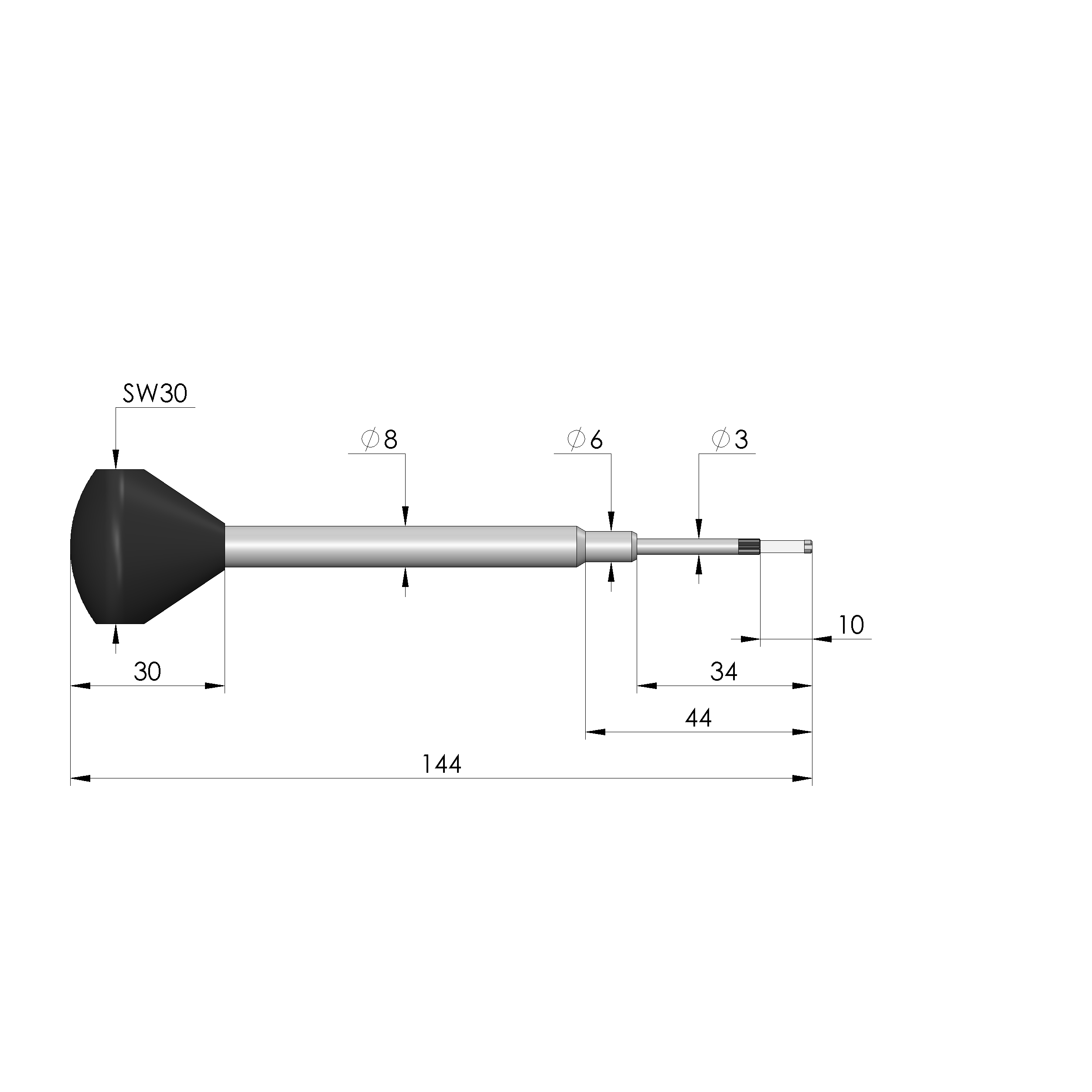

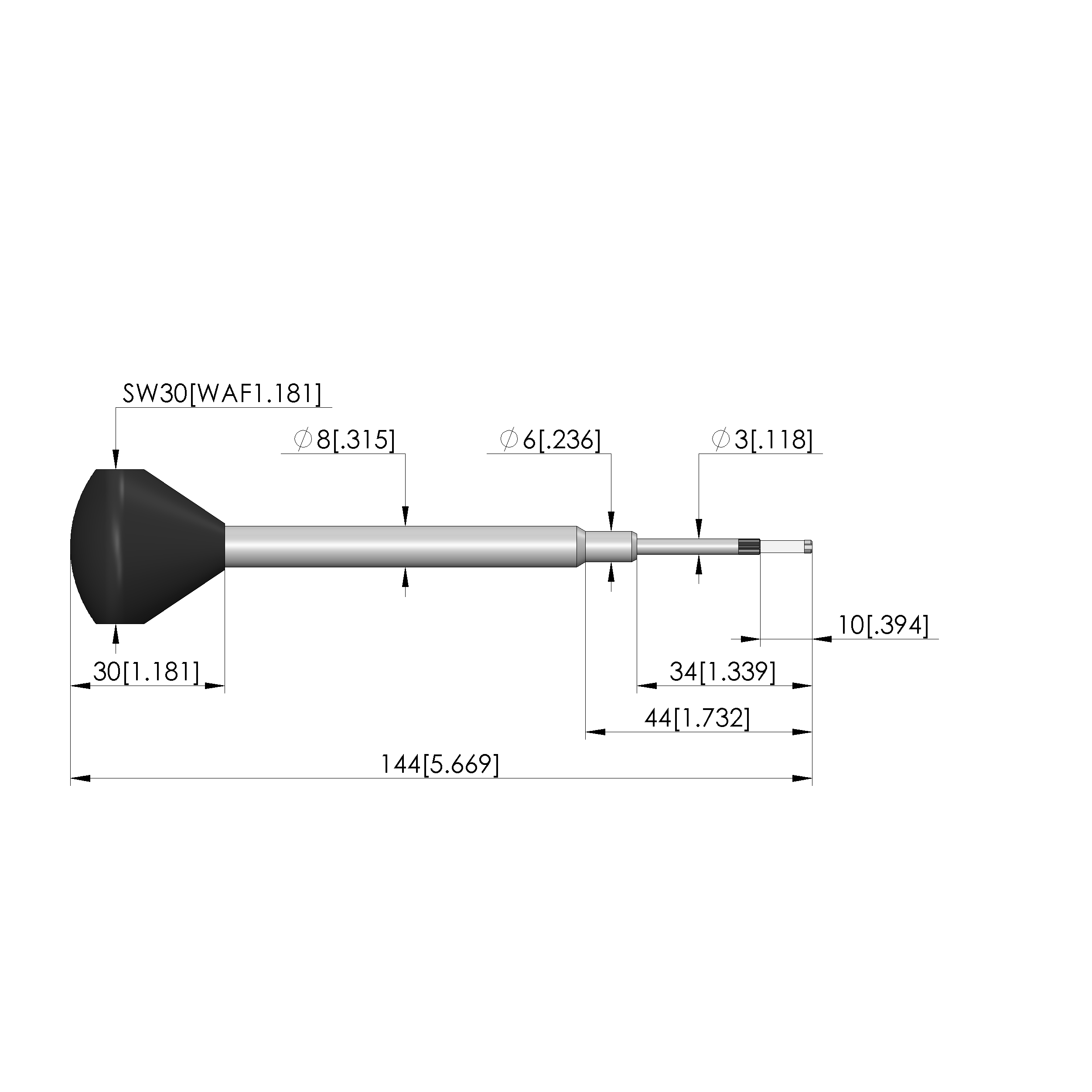

Insertion and extraction tools SW-ZW-GKS-100 Item SW-ZW-GKS-100

Insertion and extraction tools SW-ZW-GKS-100 Item SW-ZW-GKS-100

Please log in to show the price

Login

The prices listed in the scale are displayed rounded, therefore deviation in the total price is possible.

Shipping costs

* The prices are rounded to two decimal places.

Technical data

| Product group : | Insertion and extraction tools (SW-ZW) |

|---|---|

| Compatible test probe(s) / receptacle(s) : | 107 GKS-002, E-100, DKS-100, GKS-100, GKS-135, GKS-725, SKS-100 |

| Series : | SW-GKS |

| Tool for receptacle (KS) : | No |

| Tool for test probe (GKS) : | Yes |

| Test probe installation type : | Plug-in |

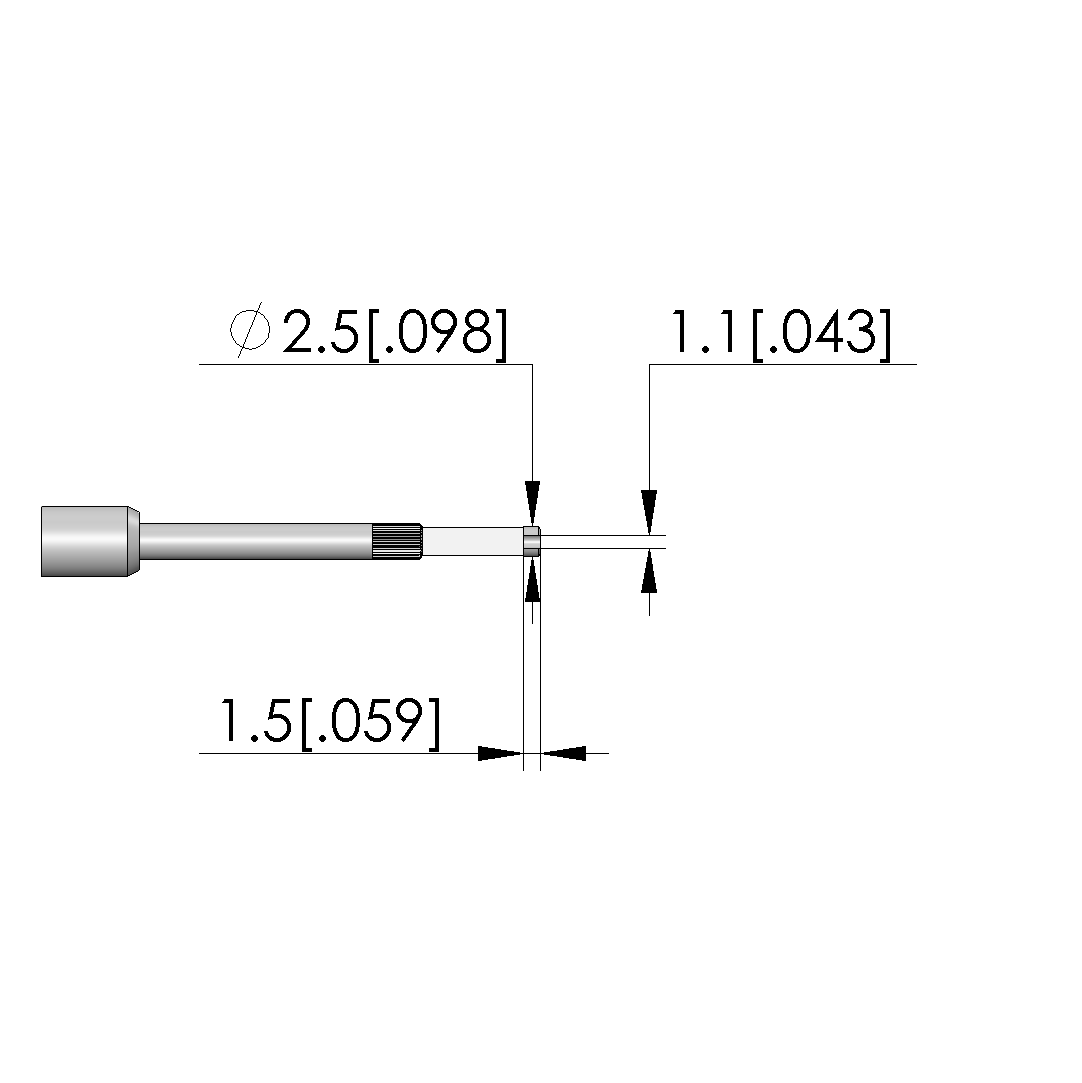

| Max. tip diameter : | 1.5 mm |

| Tool version : | Rigid |

| RoHS-compliant : | RoHS-3 |