As a revolution innovation, e-mobility is rapidly penetrating various product sectors. This creates various application possibilities that go far beyond the current possibilities of mobility. In particular, battery technology is crucial for the field of e-mobility and requires robust, reliable contacting solutions.

Increasing current/voltage requirements, as well as higher frequency ranges for the required data transmission rates, thermal influences, application-related and environmental challenges in the integration space and the test environment, are the challenges that prevail now and will continue to do so in the coming years.

INGUN meets these challenges in the radio frequency, high voltage, and high current range, as well as power electronics. Our product portfolio equips our customers for e-mobility testing and provides them with an economical, reliable, and sustainable solutions for their test requirements with worldwide availability.

High-voltage on-board network

The battery is the source of electrical energy within the e-mobility sector. It serves as a central storage unit for the supply of the individual power units and the vehicle electrical system of cars or commercial vehicles. Separately routed high-voltage (HV) cables / cable harnesses connect the battery and the power electronics, power units, and battery management modules to each other. Various connectors serve as interfaces, which at the same time represents the test application. INGUN meets the challenges of the lowest contact resistances, four-wire measurements, and thermal sensor technology at the terminal, as well as the limited space of the contact point while under the highest current loads.

Radio frequency

The cars of the future will be able to drive partially or fully autonomously and will be equipped with Advanced Driver Assistance System (ADAS) technology. This will be accompanied by an ever-increasing number of intelligently communicating components. These cause a higher data volume and consequently increased communication frequency. Central computer systems must be able to collect and interpret this sensor data in real time to control the actuators for autonomous driving. Intercommunication between vehicles (vehicle-to-vehicle, or V2V) and with external networks (vehicle-to-everything, or V2X) is possible via 5G/6G radio interfaces. The resulting high data rates are transmitted via radio modules/antennas, which also represent the test content. In order to be able to test these modules functionally end-of-line, it is necessary to flash software onto the microcontroller as a partial or independent process. For reliable transmission of current, voltage, frequency, and data INGUN offers a large portfolio for all commercially available connectors.

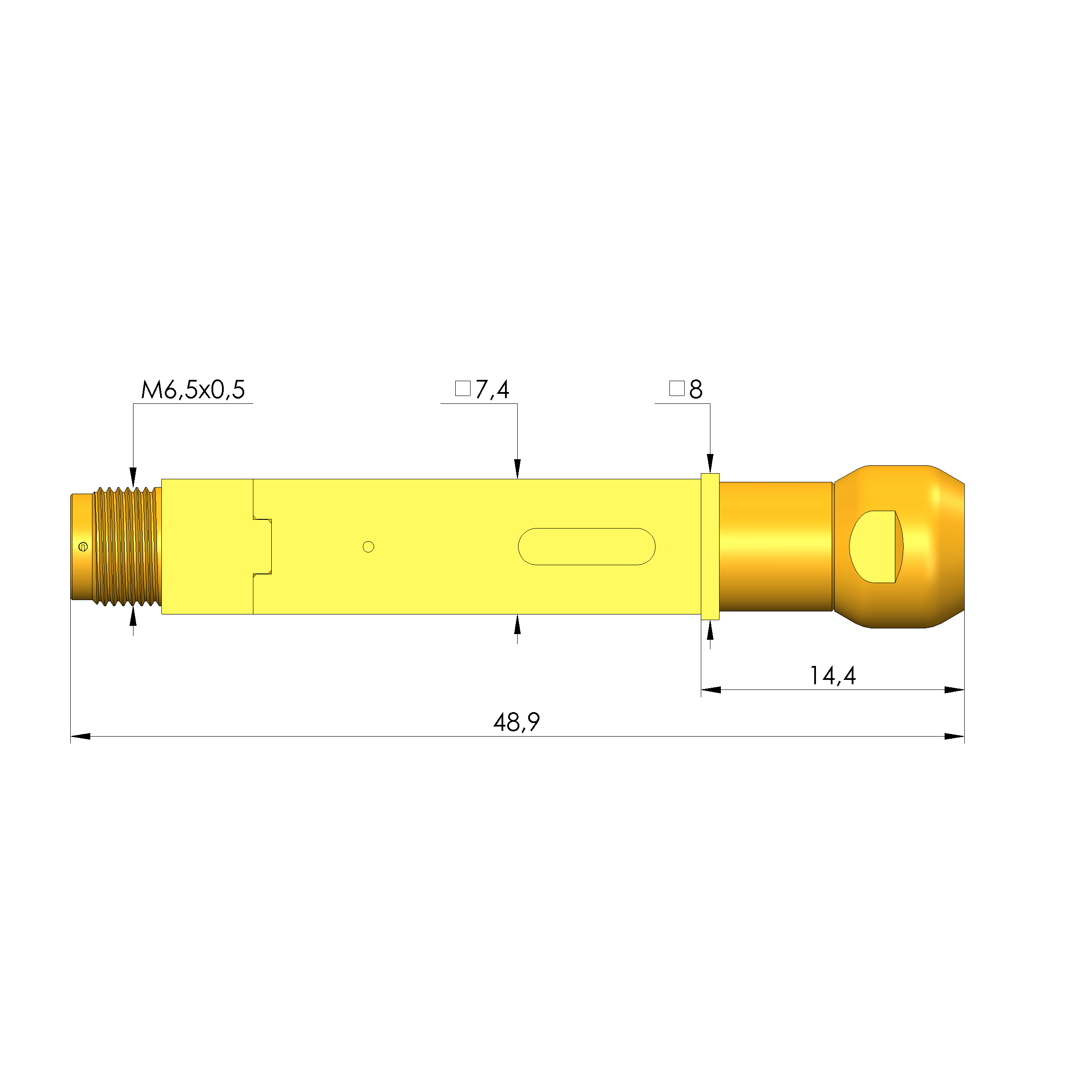

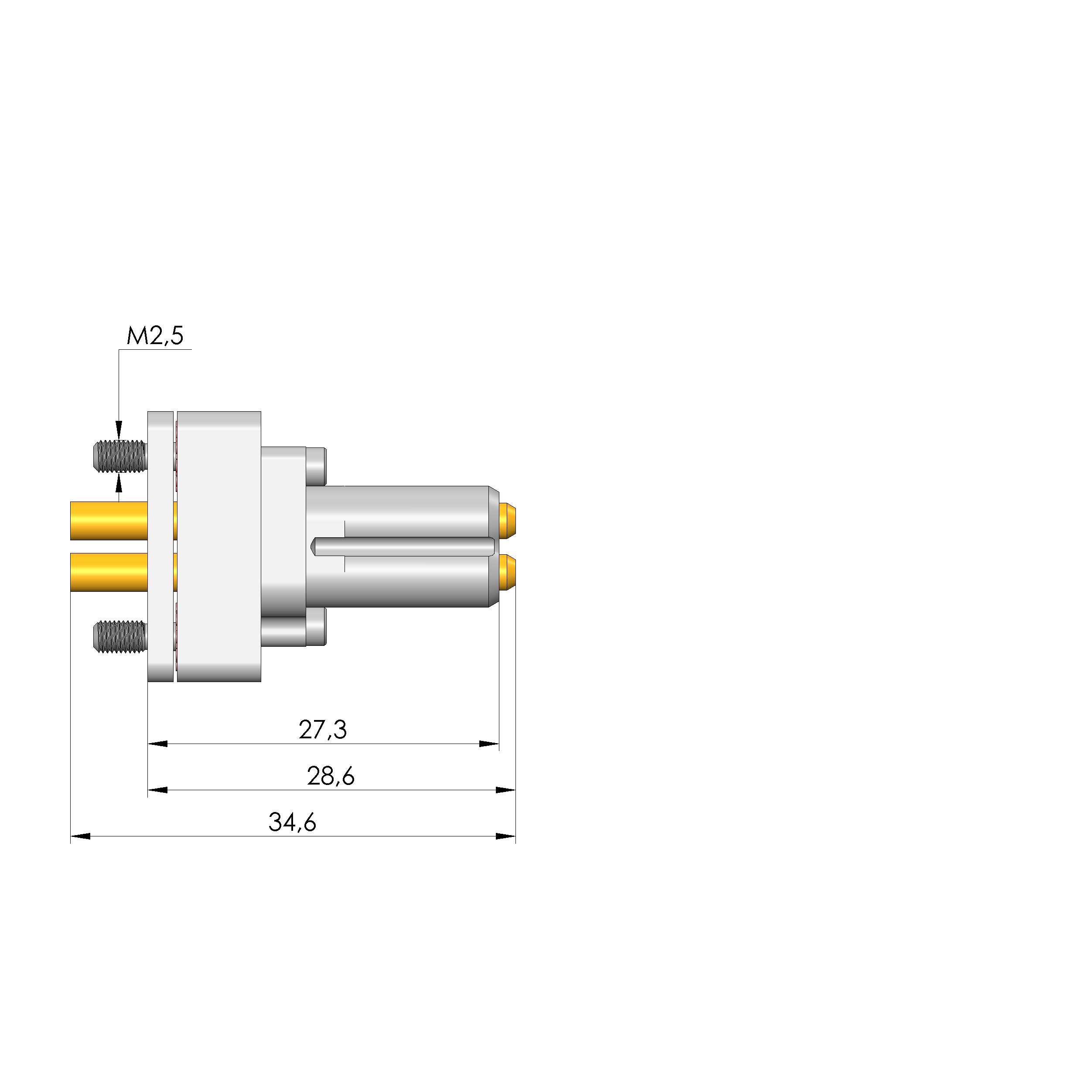

Cable harness

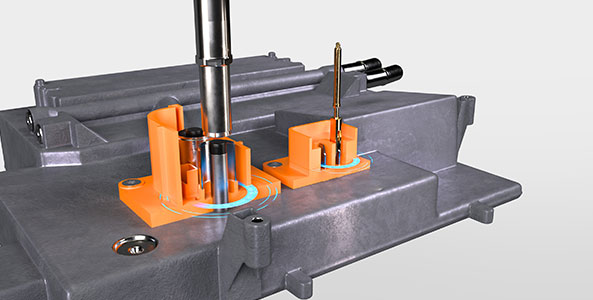

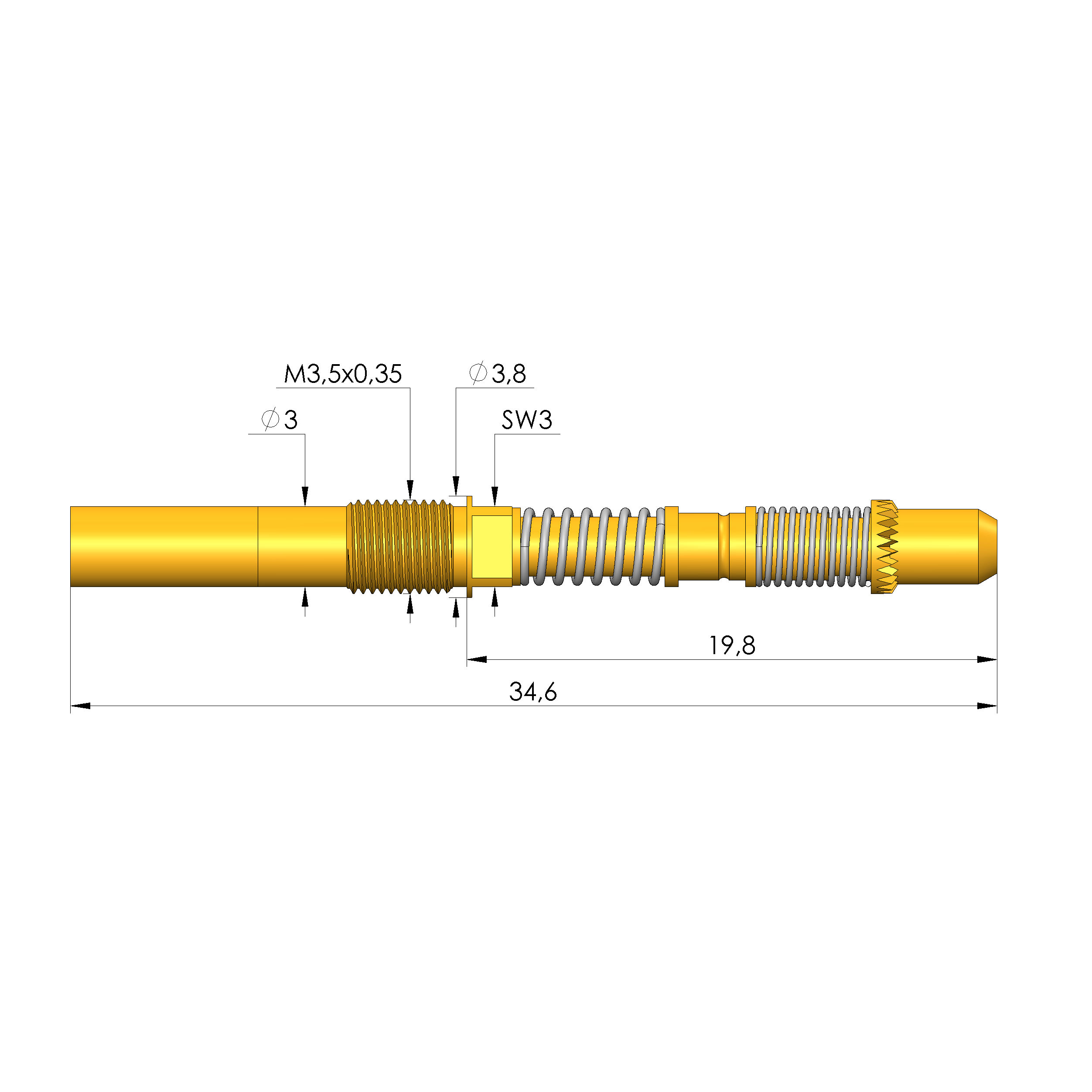

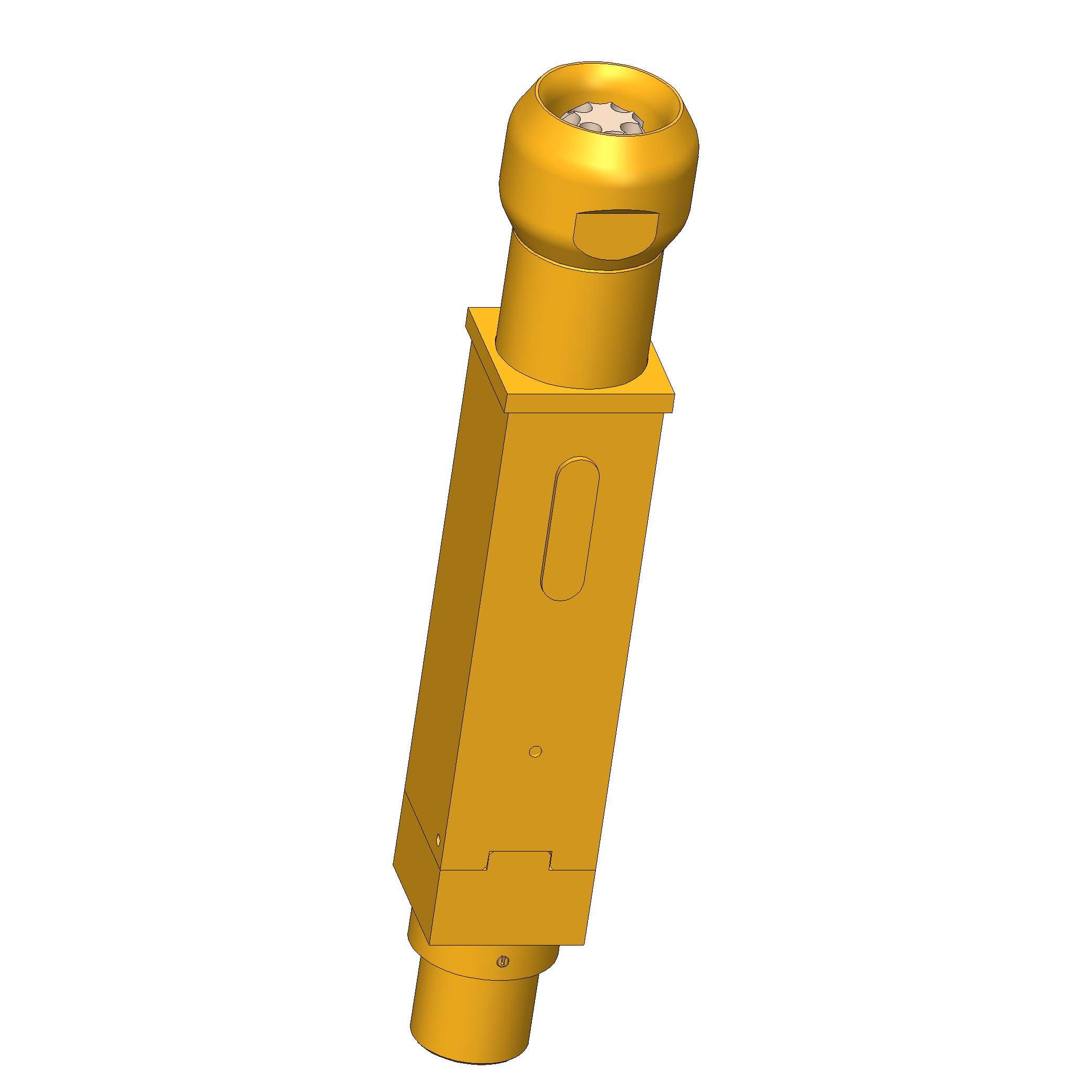

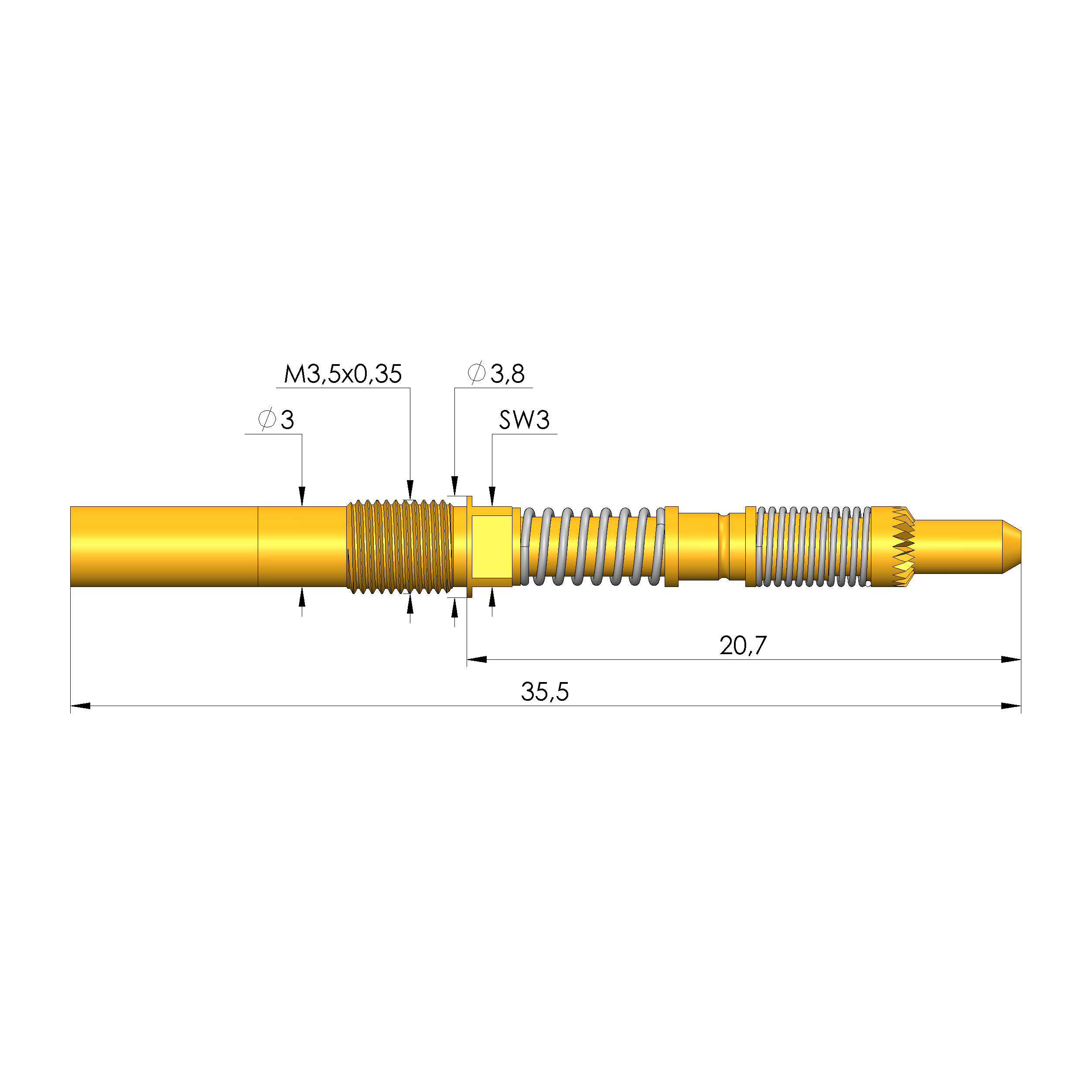

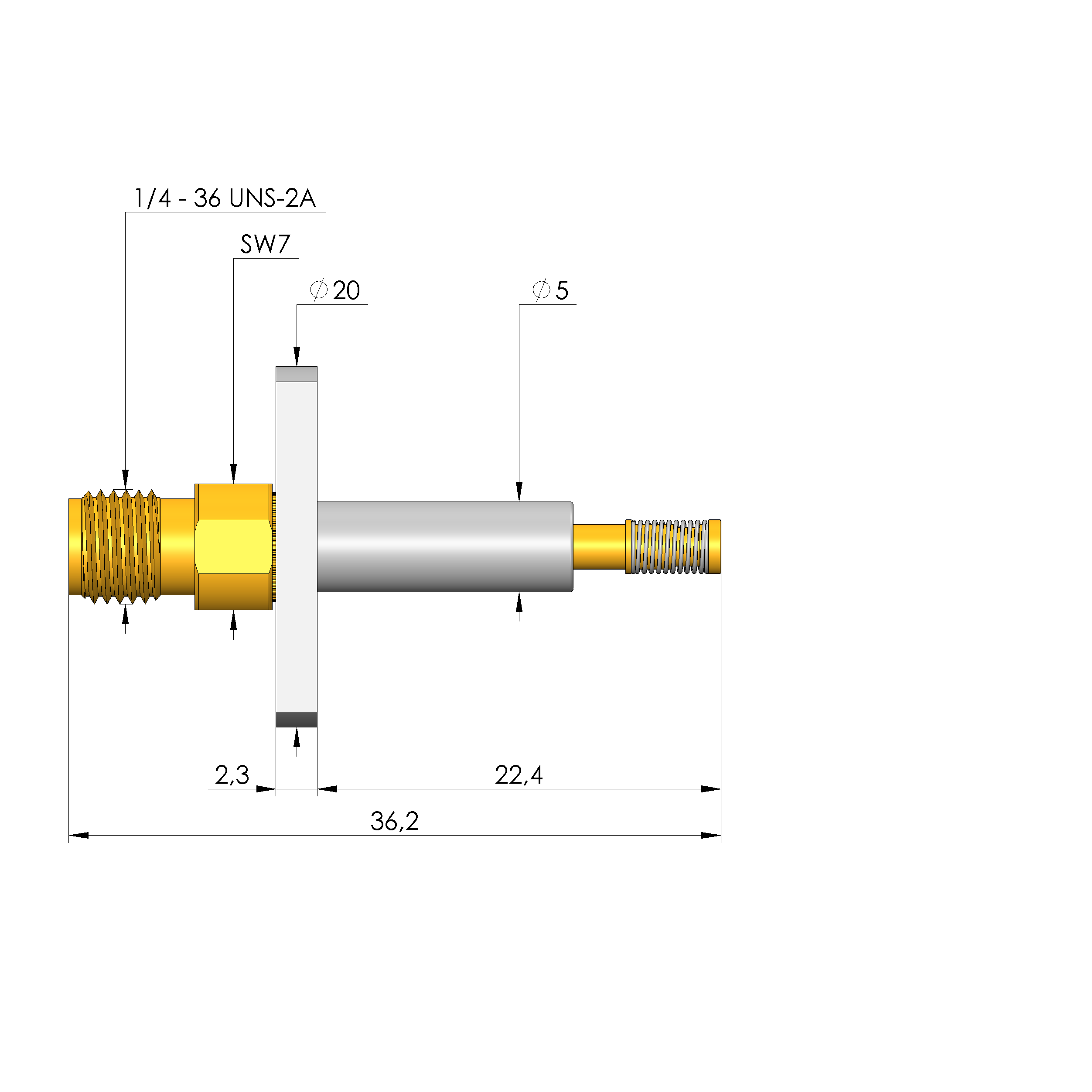

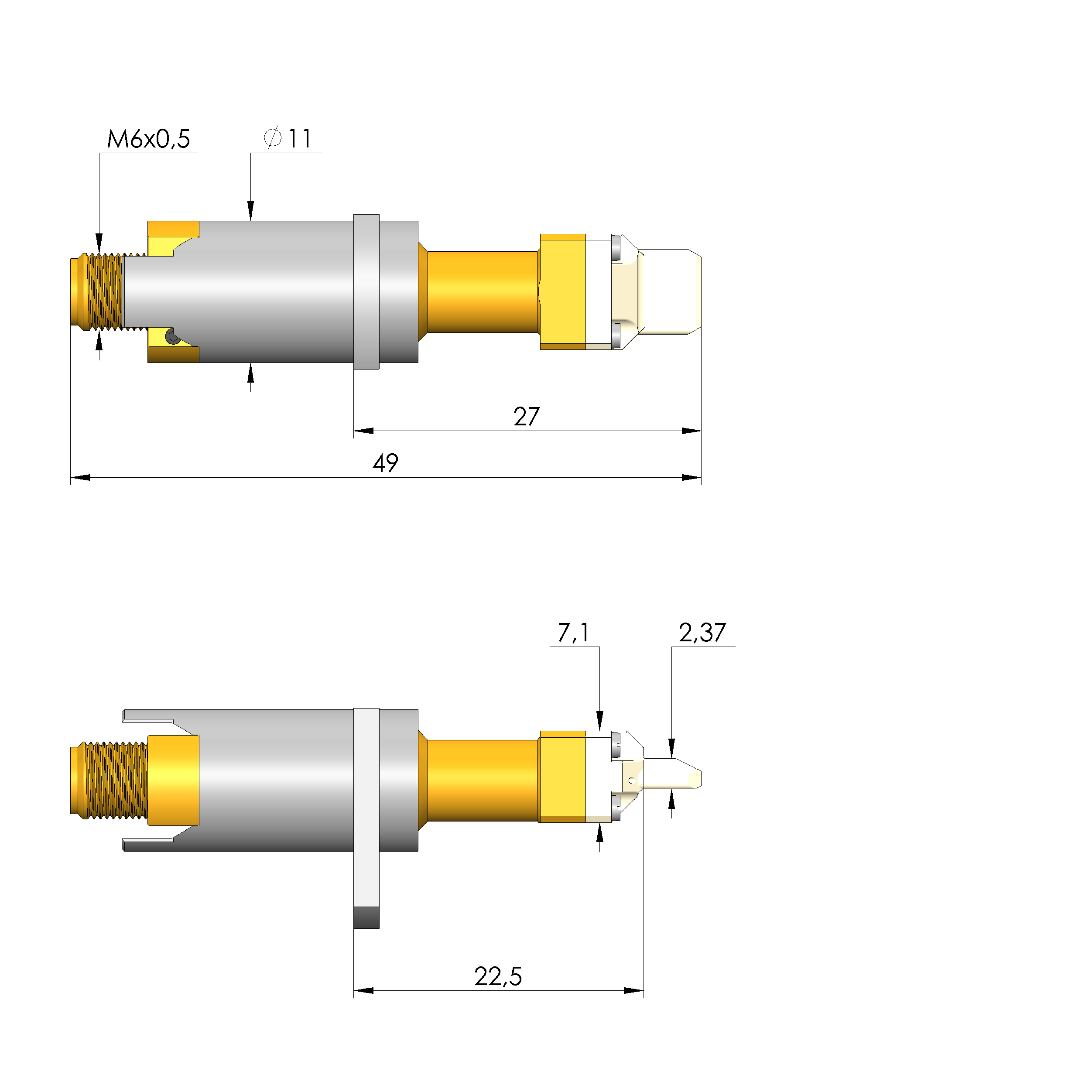

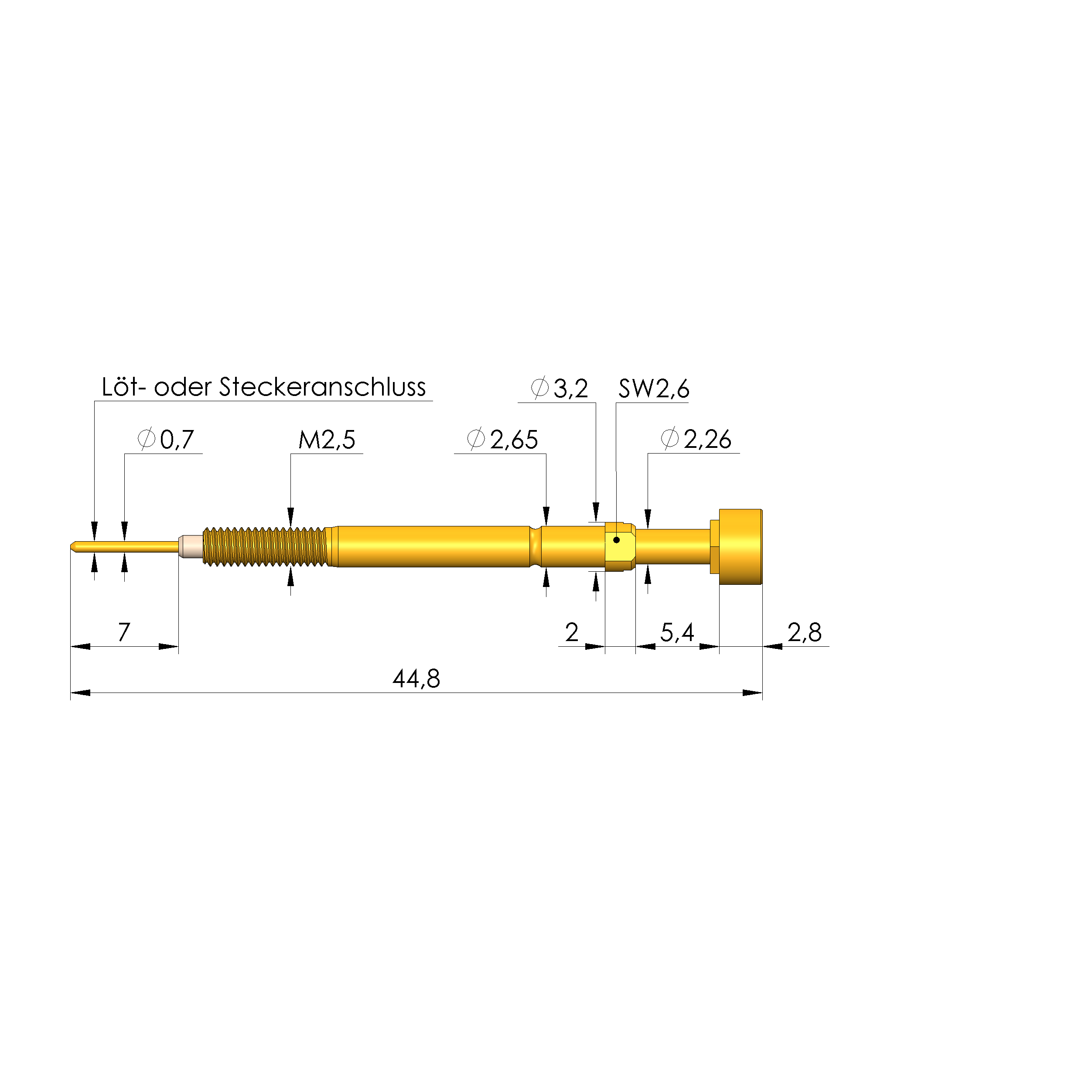

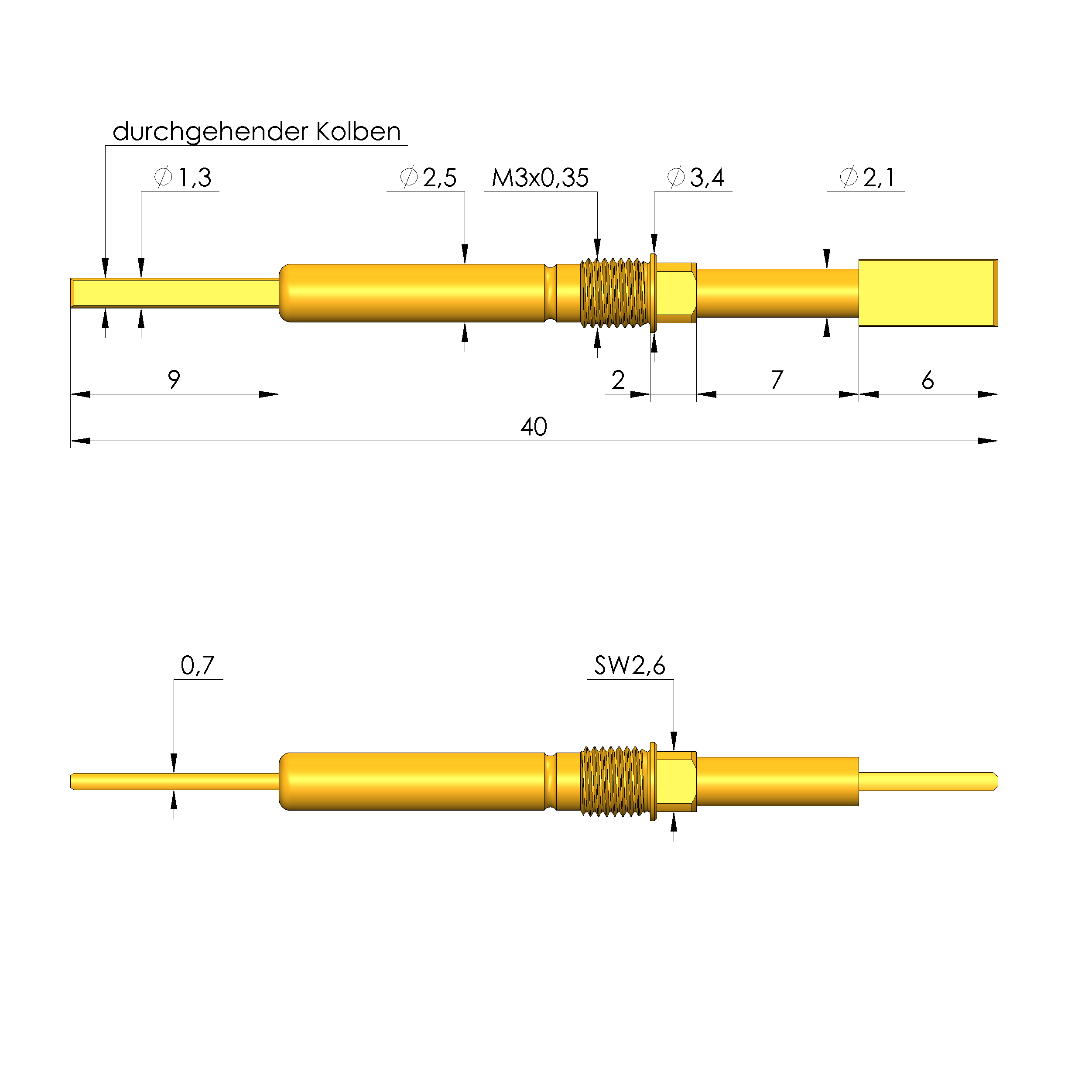

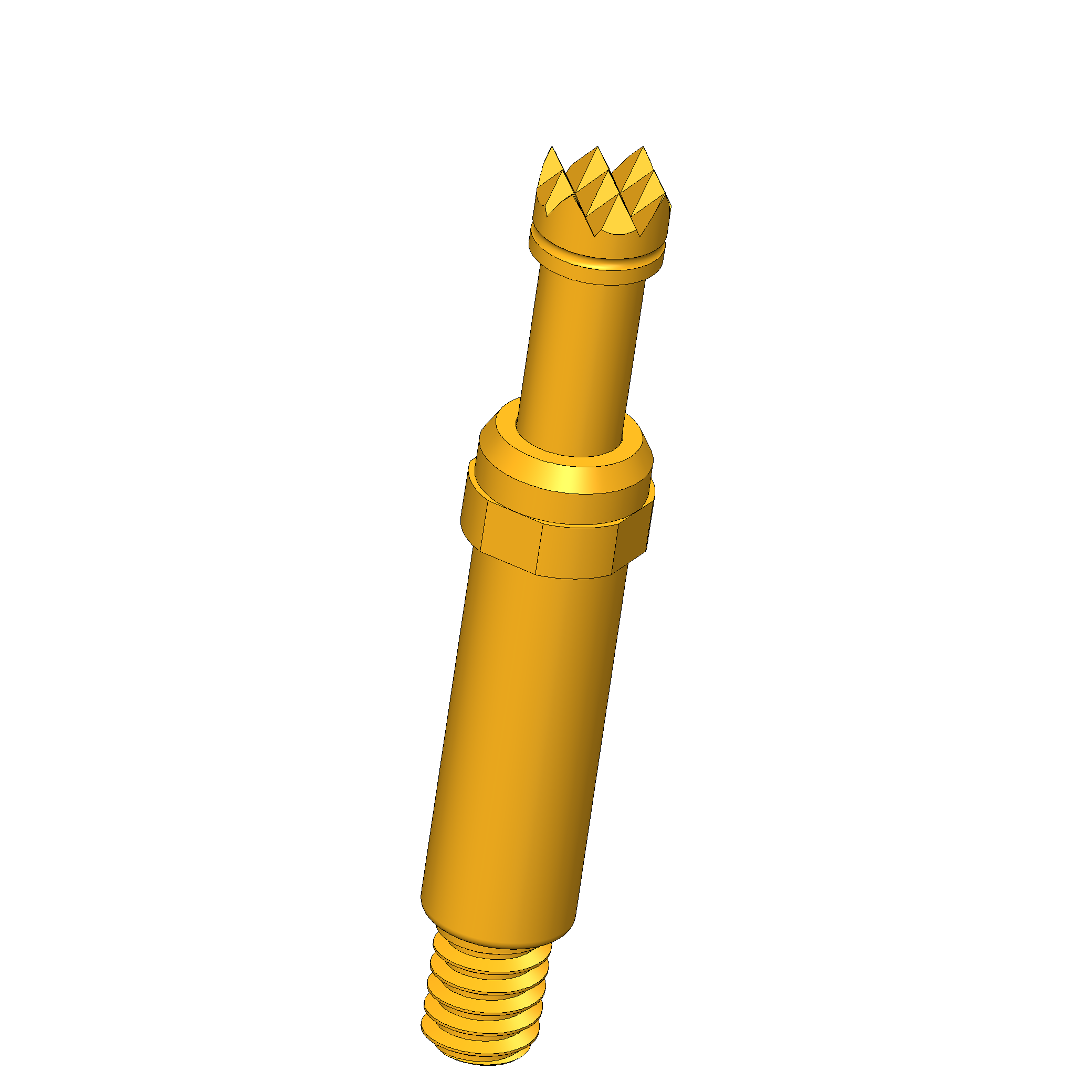

In the automotive sector, cable harnesses are the central connecting element between different electrical units. A cable harness consists of several cables with assembled plug connectors which transmit either power or signals. These connectors are subjected to an assembly test, insulation measurement, high-voltage test, and many more tests with the help of INGUN test probes on cable test tables. This ensures reliable contact in the simulated mated state in the test environment. The additional screw-in connection between test probe and receptacle ensures a secure hold during the test.

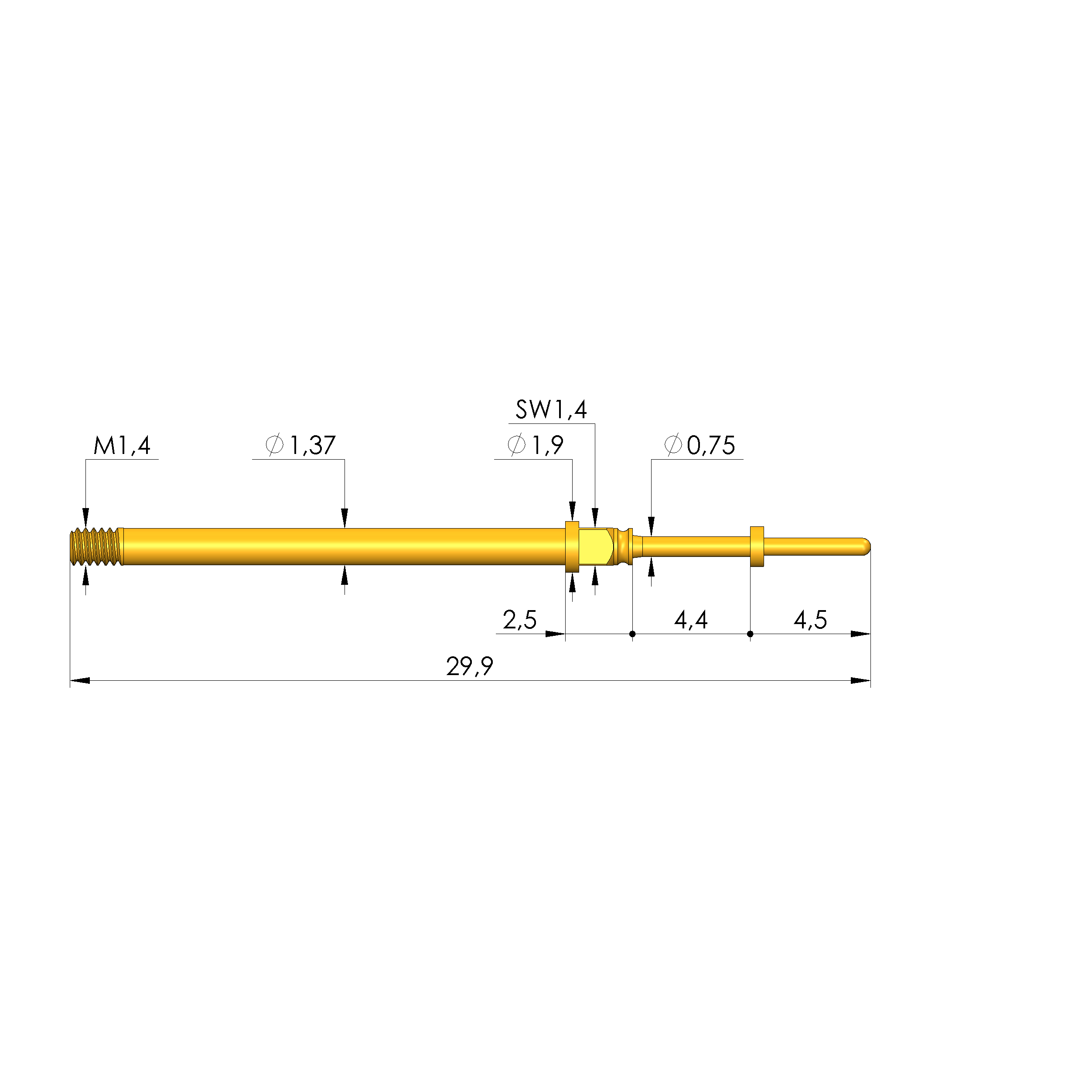

PCB

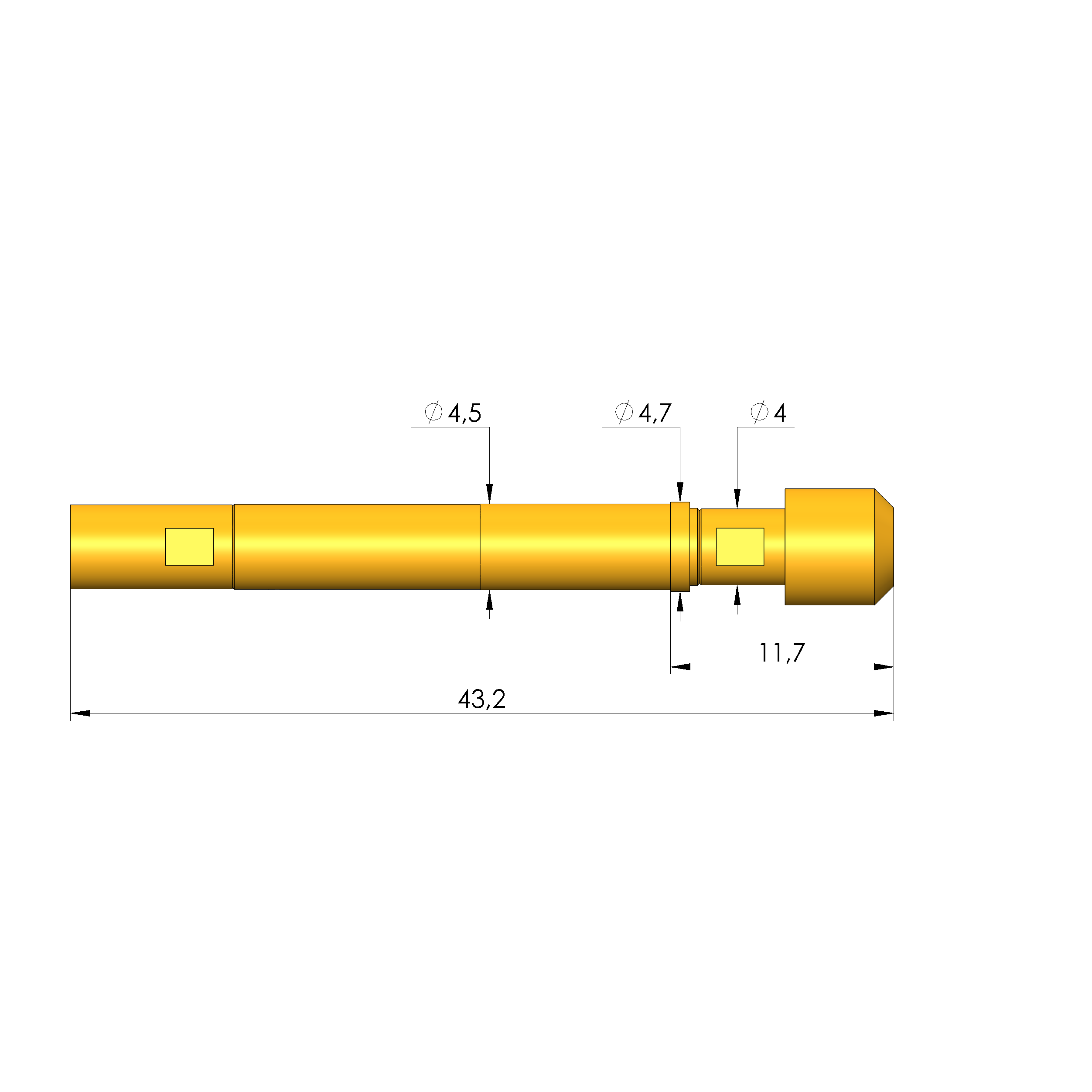

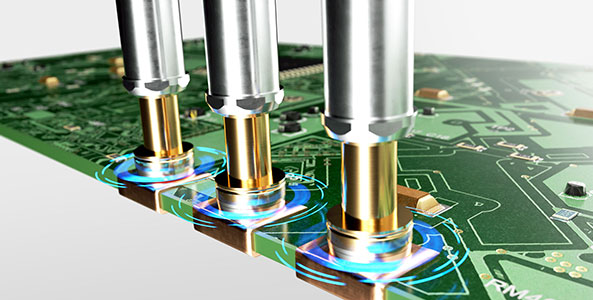

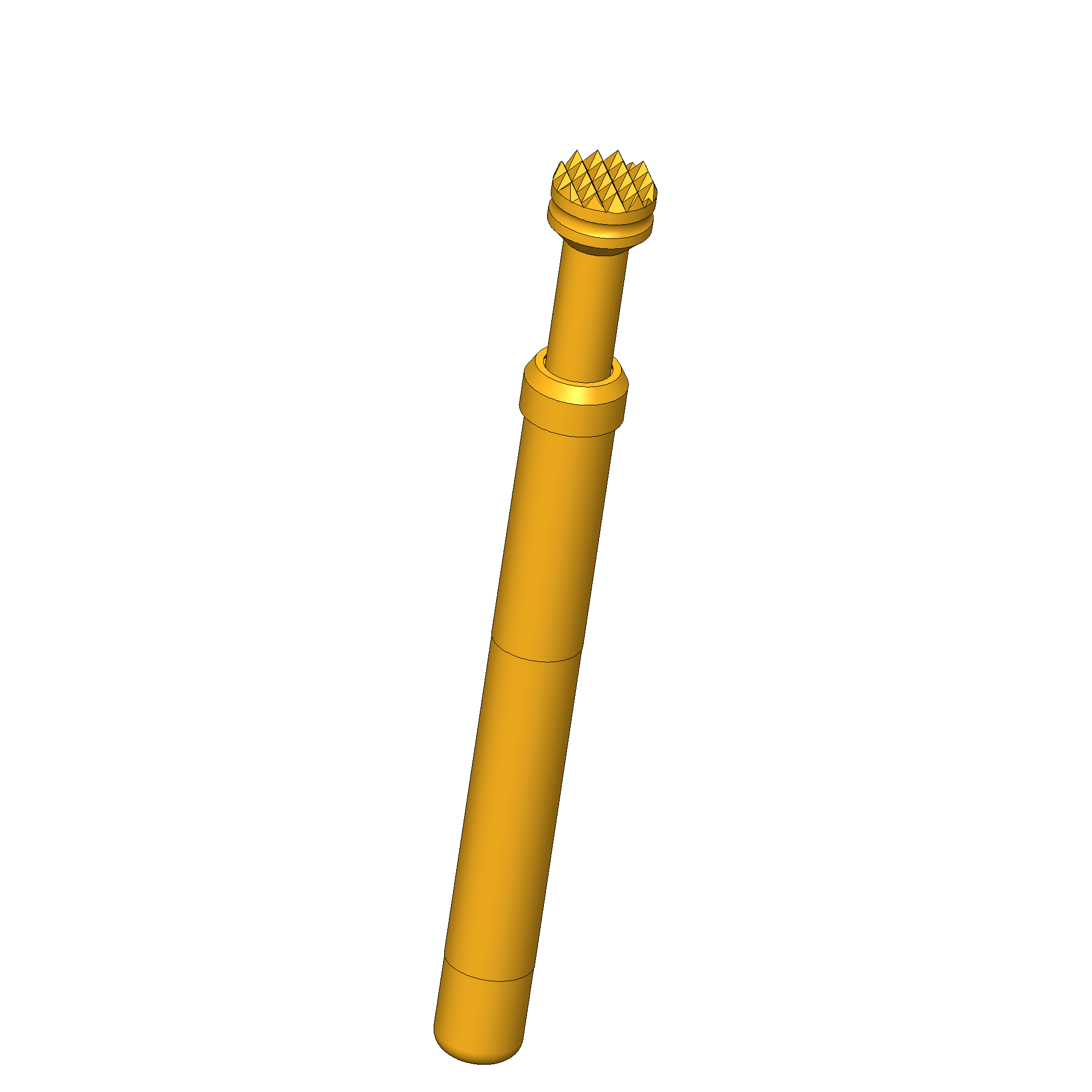

Especially for voltage conversions for inverters DC/AC, rectifiers AC/DC ,or DC/DC pulse modulations, high current or direct copper bonded PCBs are a core element in power electronics for e-mobility and in the automotive sector. During the manufacturing process, 100 percent of the PCBs undergo testing. INGUN ensures reliable, robust contacting for functional or end-of-line tests under real and climate-controlled conditions.

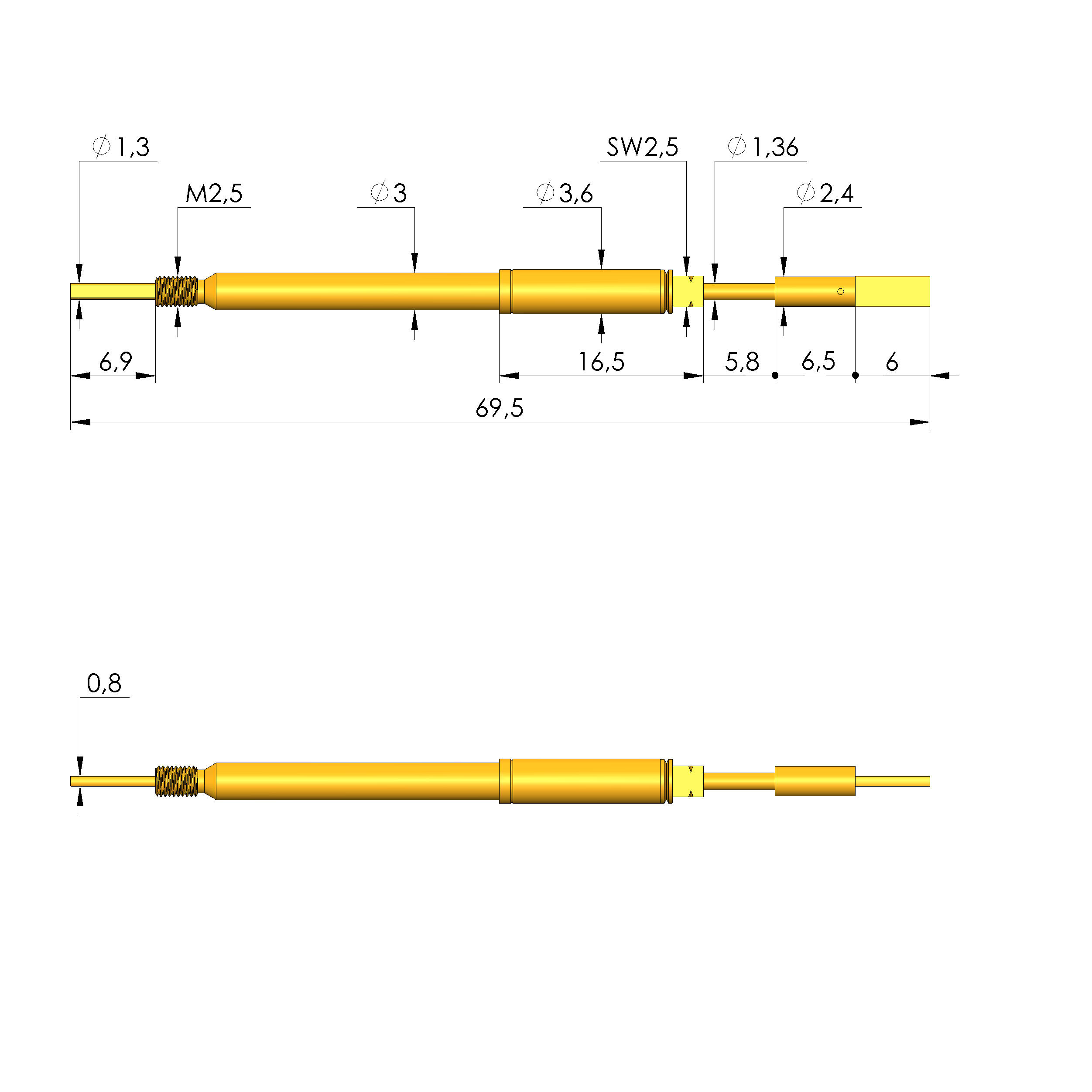

Power elements

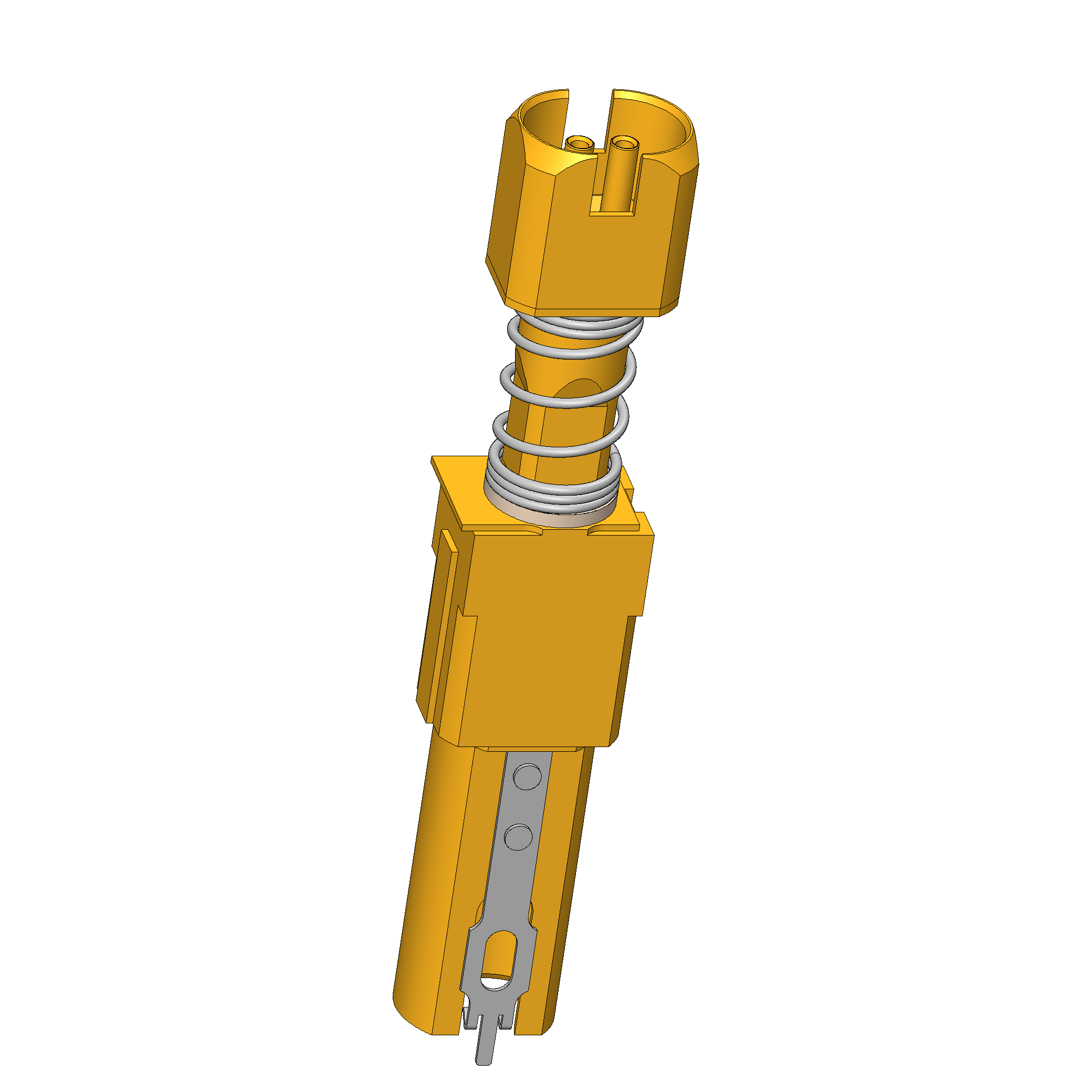

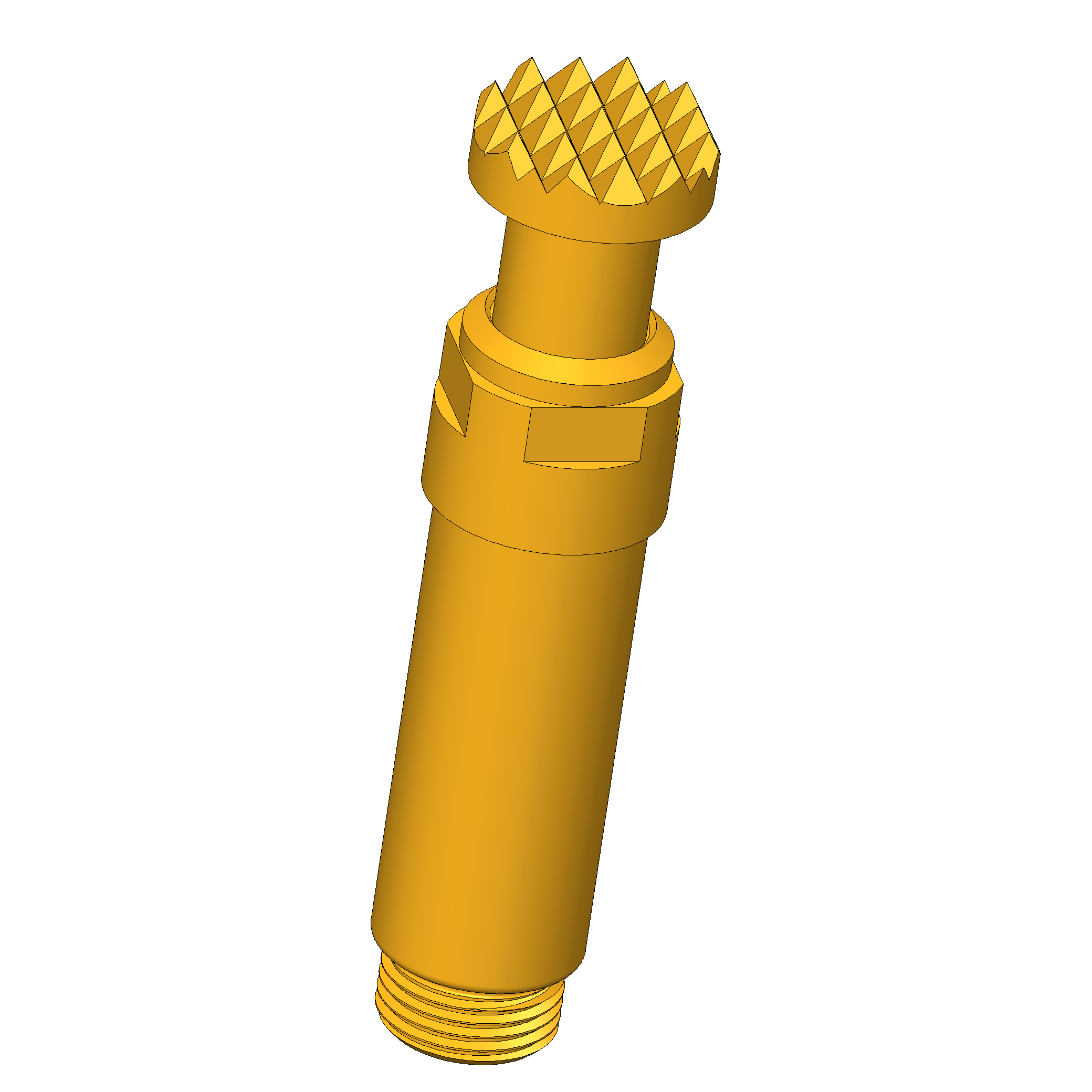

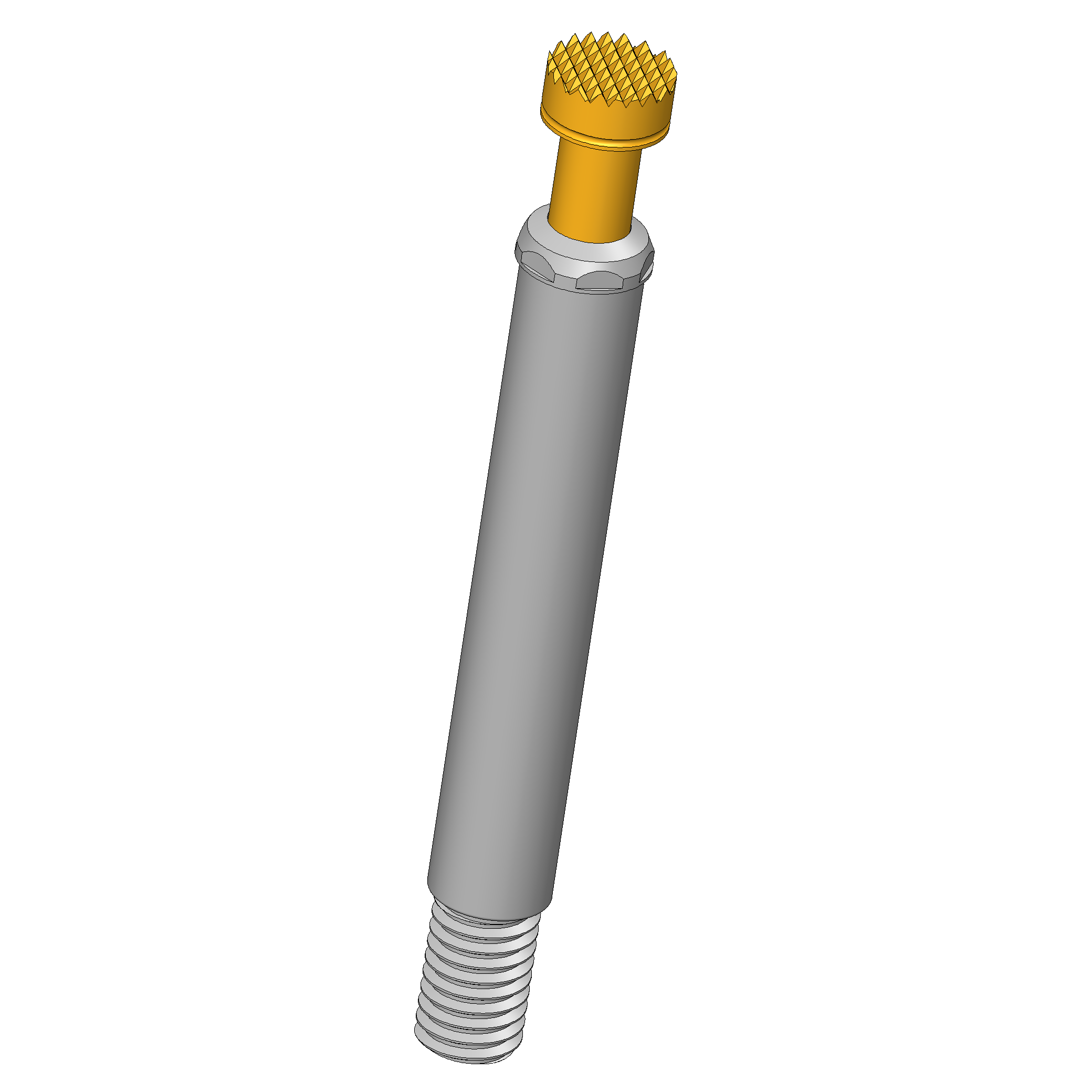

Power elements (wire to board) can be used to realise the external interfaces of a printed circuit board for connecting the feed and supply as well as distribution to consumers. These through hole technology (THT) or press-fit high-power elements serve as electrical connection points for high currents of up to 600 amperes. In order to create an optimal contact point, high-quality, stress-free and residue-free contacting is required.