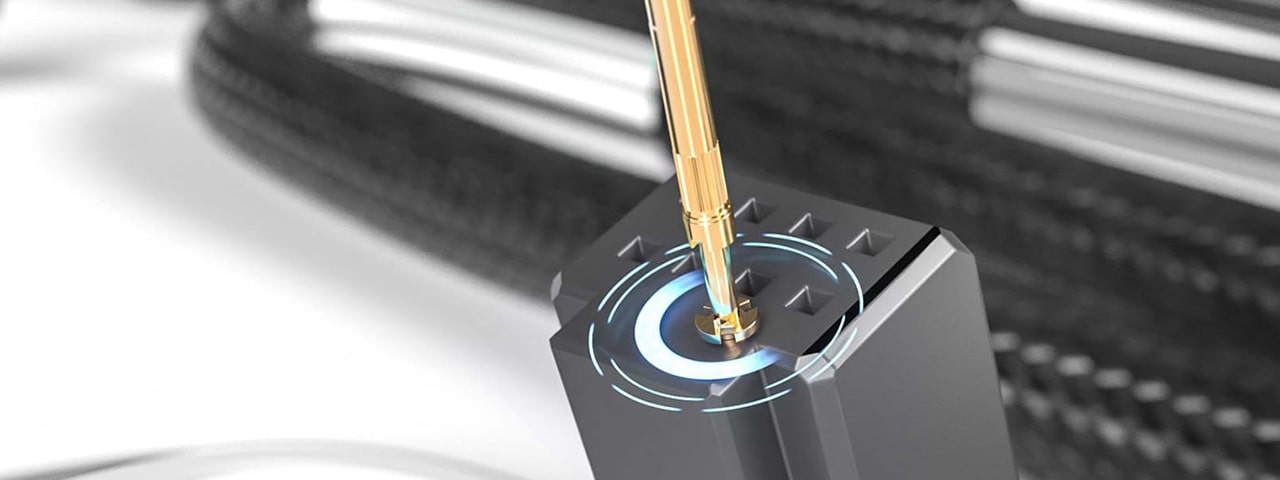

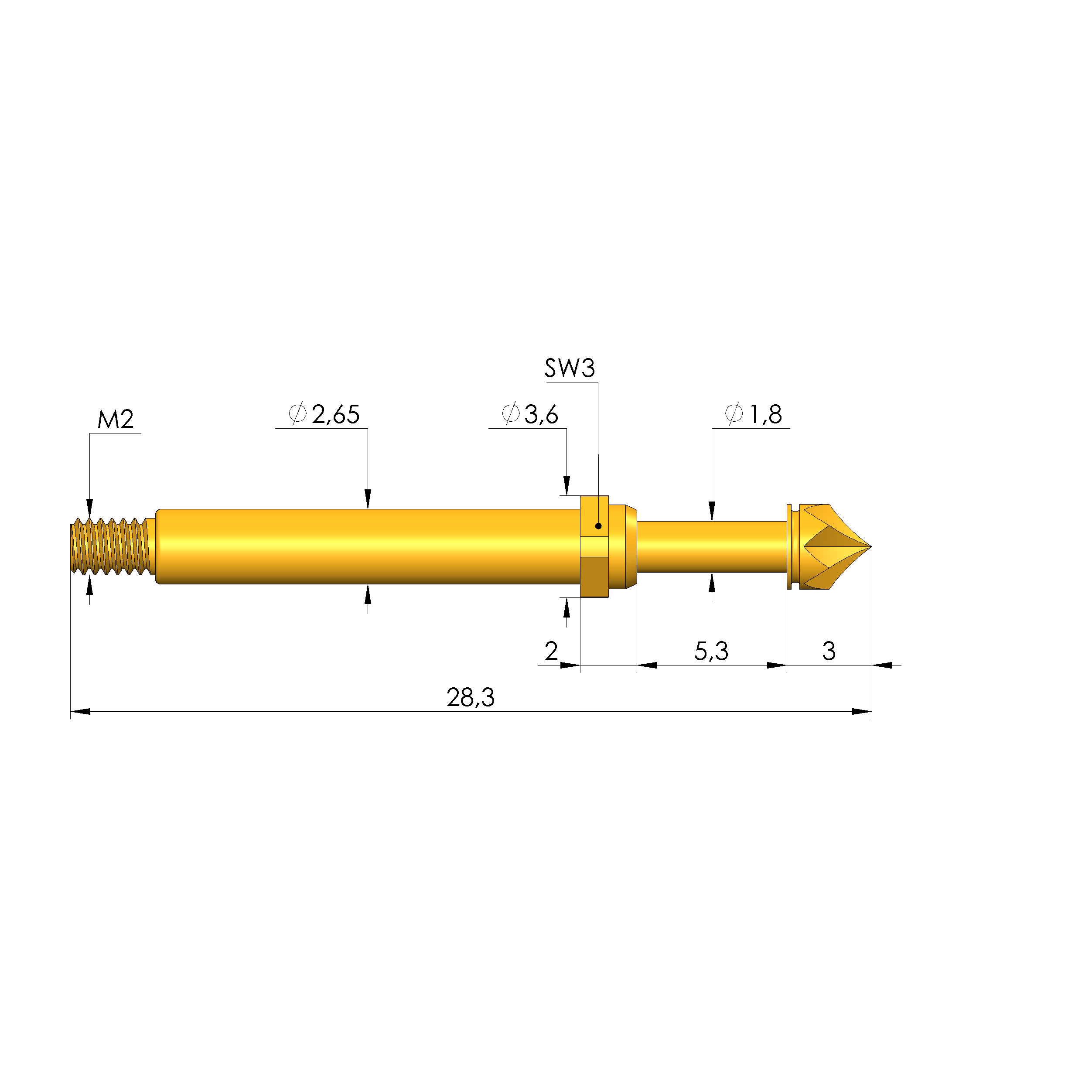

Screw-in test probes are often used to contact cable harnesses and plug connectors. They remain securely positioned in the receptacle even under challenging test conditions with vibrations, side forces or axial forces.

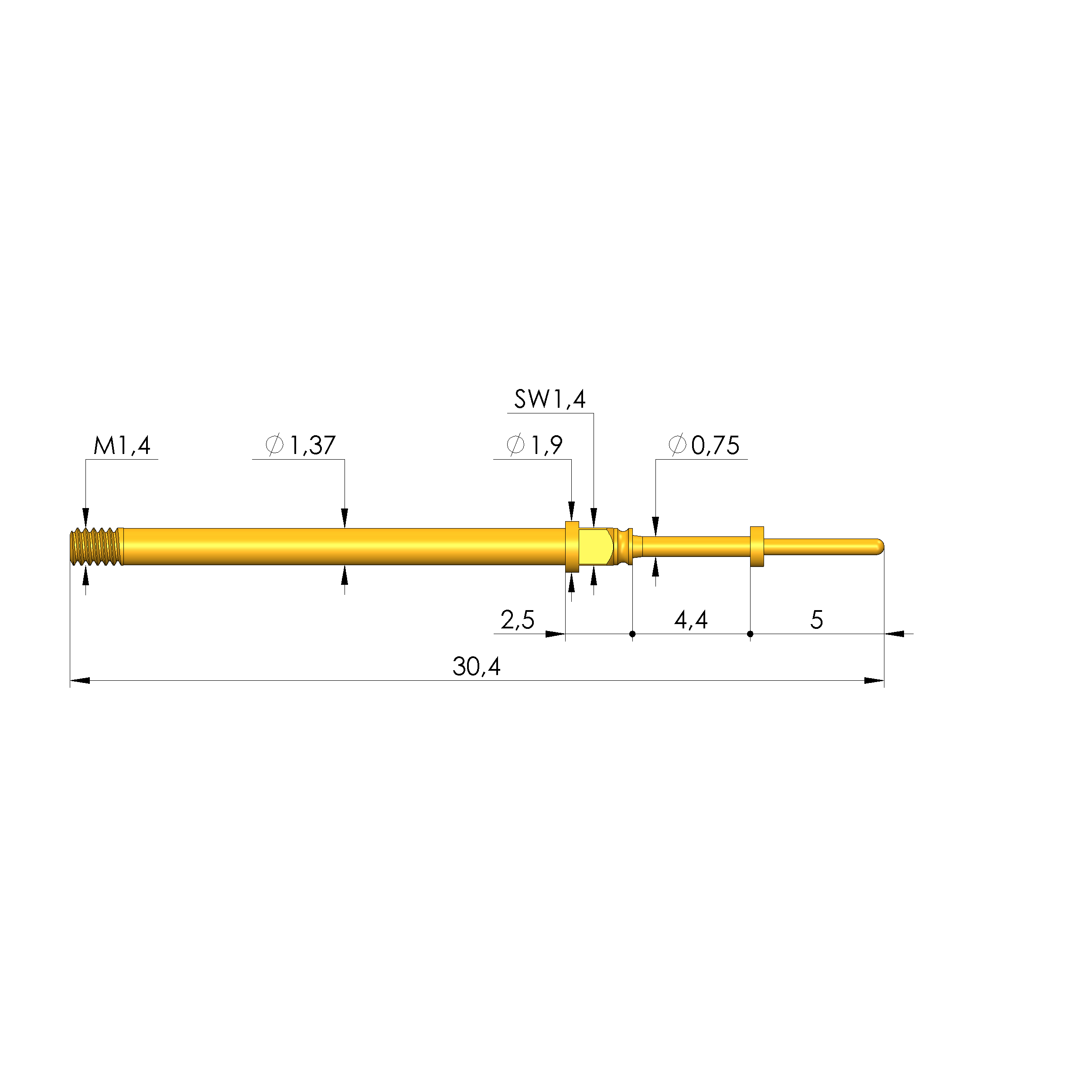

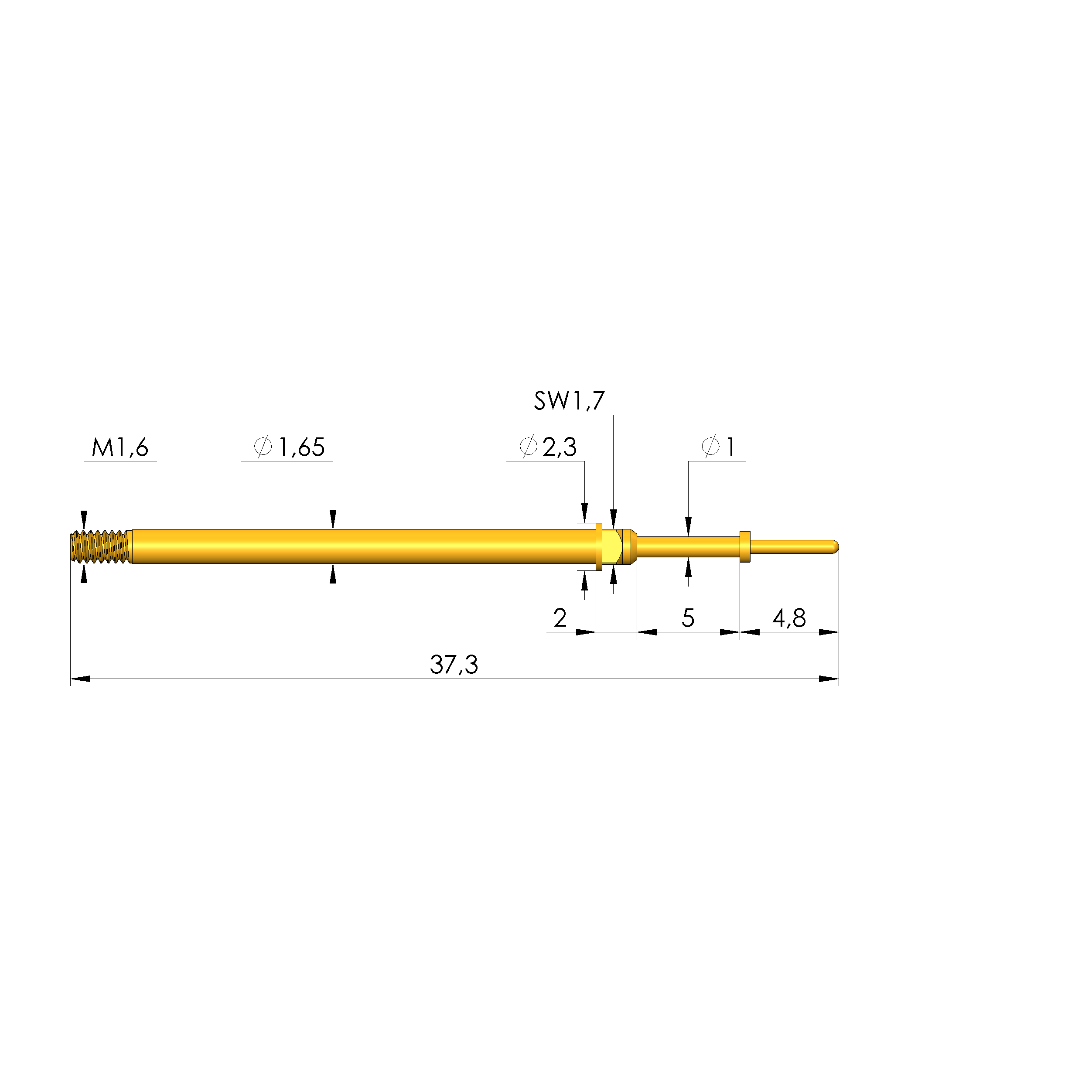

Many press-in spring-loaded test probes (GKS) offered by INGUN are also available as a screw-in version, which guarantees a secure hold during testing. Screw-in test probes with thread have the designation “M” at the end of the part number.

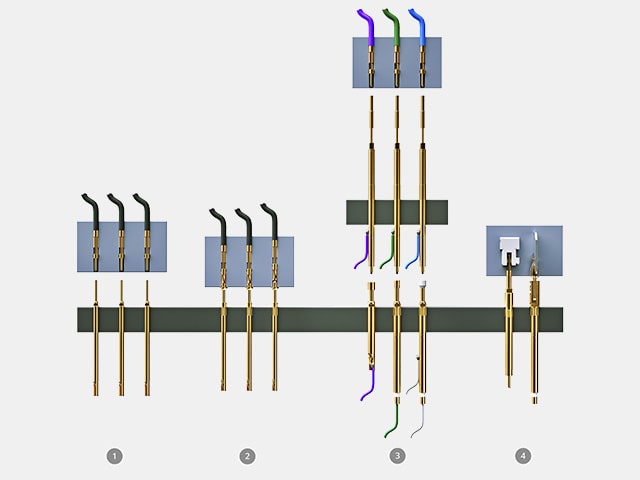

- Screw-in probes - Connection test for pin configuration test in plug housing

- Step probes - Position test for contact terminal in plug housing

- Push-back probes in combination with test probe (GKS) or switching probe (SKS) - Contact terminal push-back test in plug housing

- Non-rotating test probes - socket contacting

The right test probe for every application

Cable harnesses are the central connection elements between various components in the automobile and mechanical engineering industries and supply these components with either power or signals. To guarantee uninterrupted operation, high demands are placed on the cable harness as well as the plug connector used. The cable harness has to pass various tests before it is fitted, these include: connection test, position test, push-back test, and function test.

A further area of application for screw-in probes is the contacting of plug connectors on various electronic devices, such car radios, control units, PCs, smart devices, and many more.

Screw-in probes for specific applications

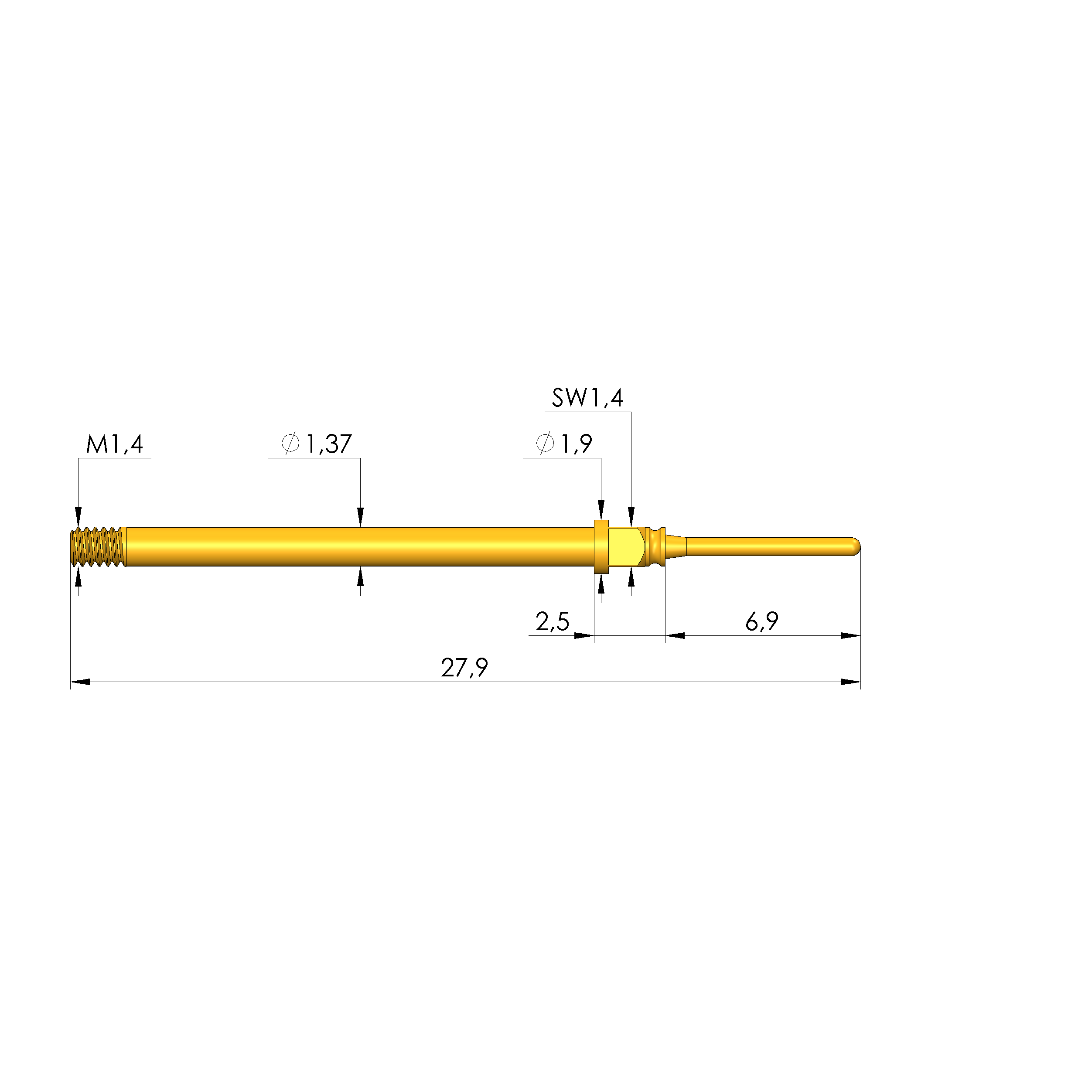

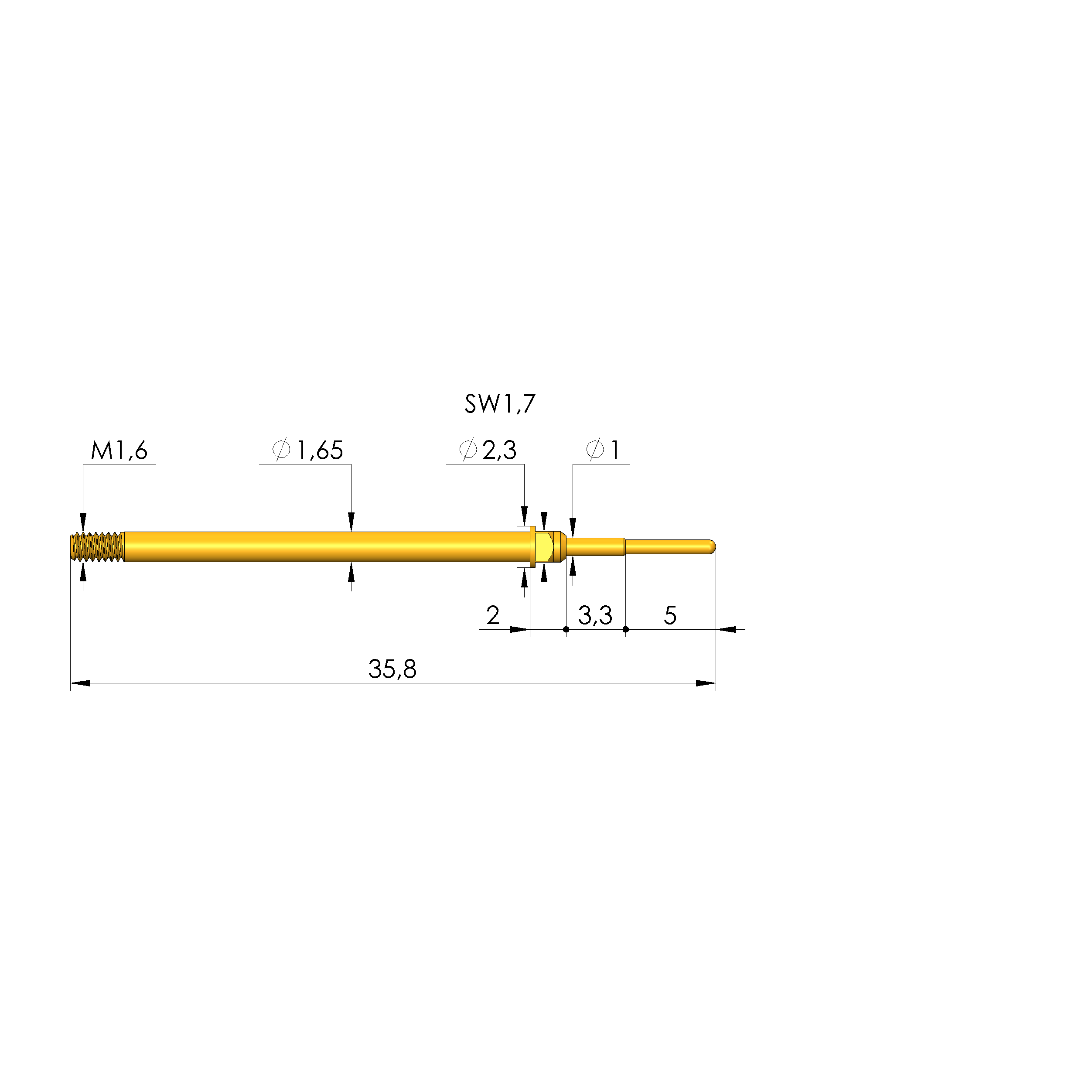

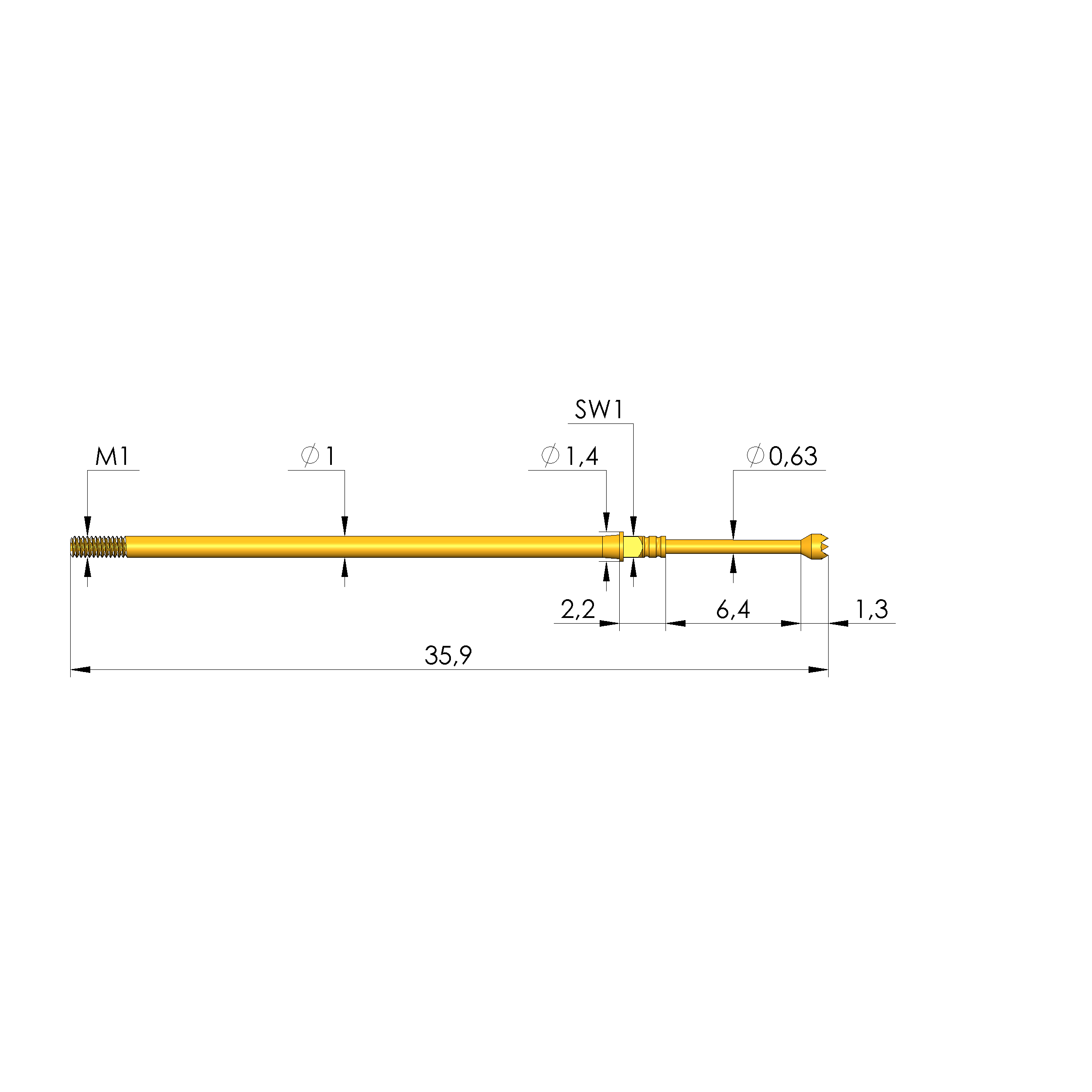

Step probes are used in the plug housings to test the correct position of the contact terminals (contact lamellae). Contact will only occur when the tip of the step probe is correctly positioned. INGUN offers a wide variety of step probes with tip dimensions, stop collar (disk) dimensions, and pin length.

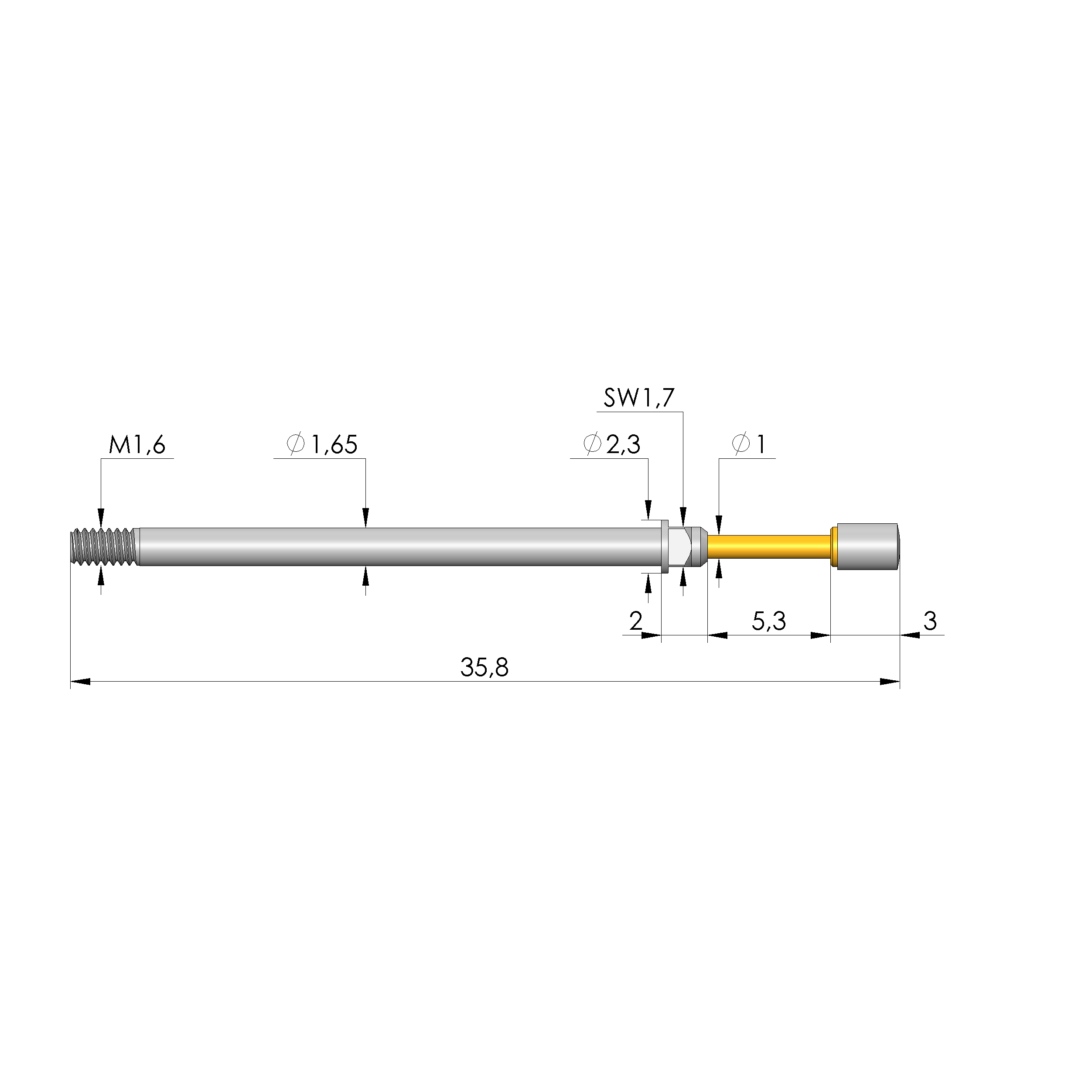

When finally plugging the plug connectors together, it is important that the contact terminals (contact lamellae) remain in the correct position, and cannot be pushed back. For this test, push-back probes with a spring force of up to 34 N are used.

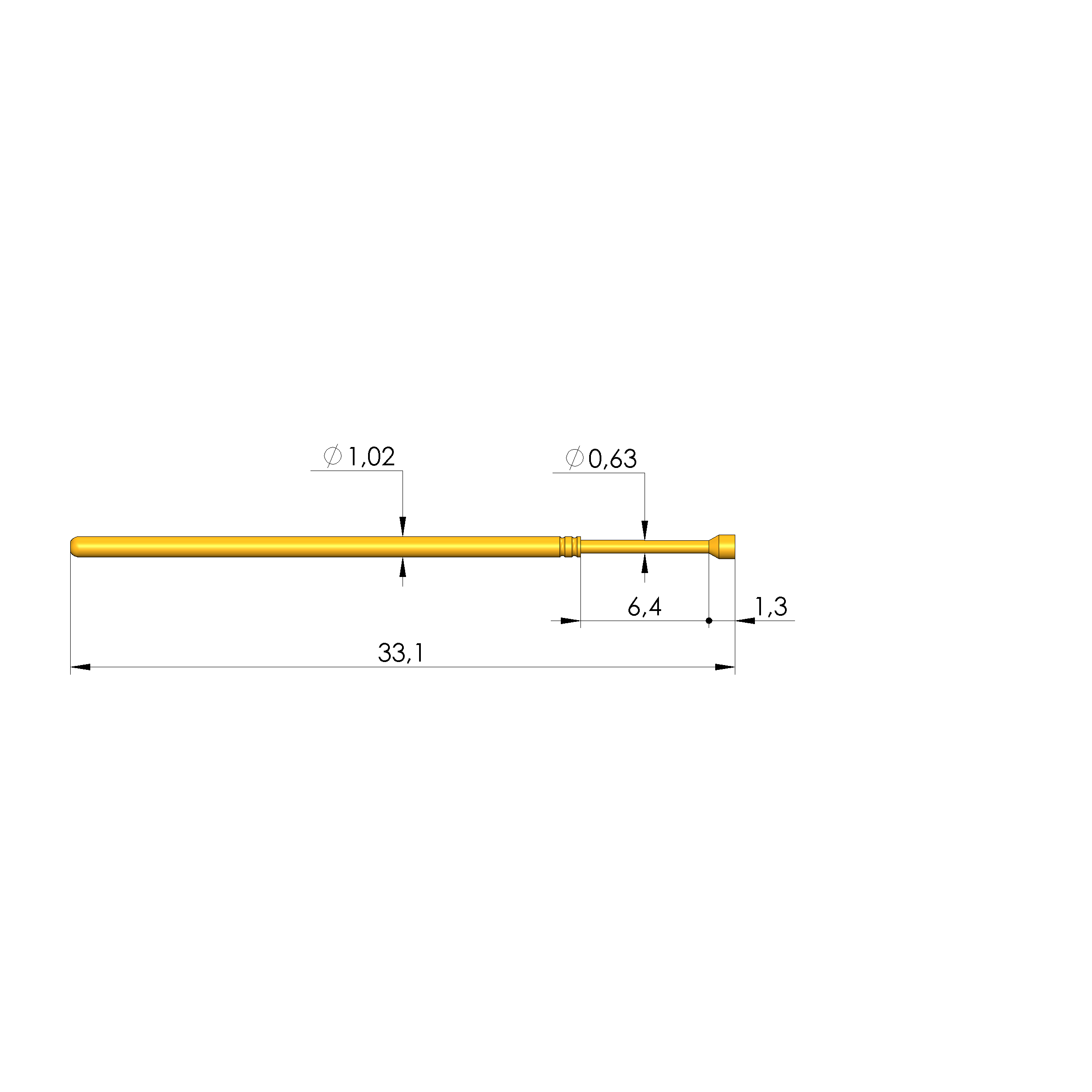

For testing flat connector blades or jacks which can only be contacted in one position, non-rotating probes are used. These probes are already aligned in the correct position during installation.