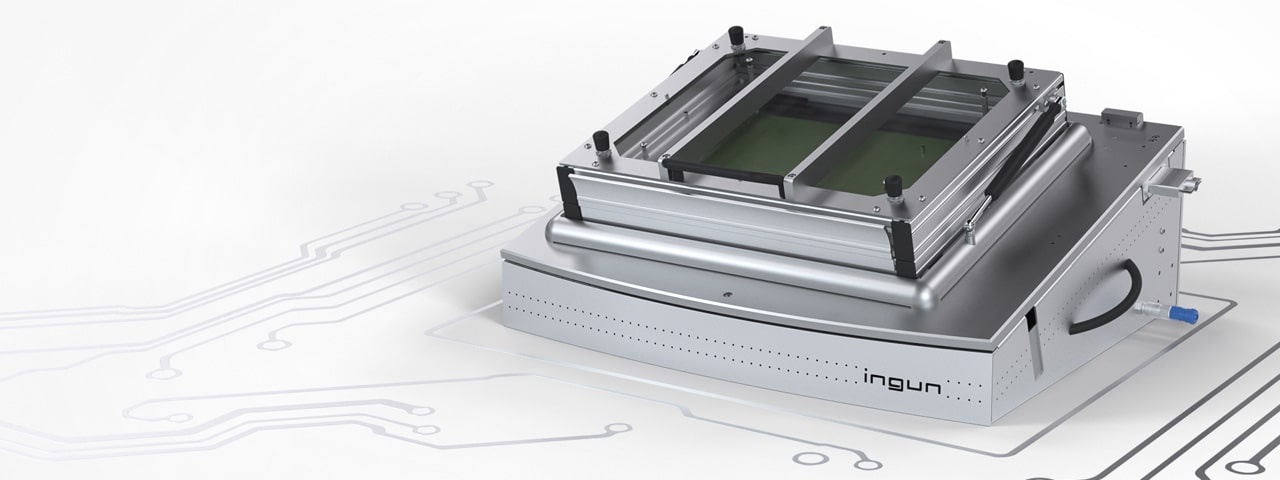

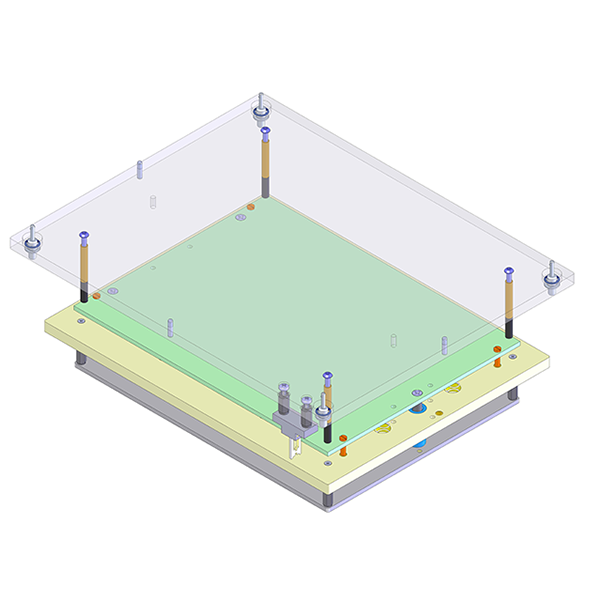

Pneumatic test fixtures from INGUN are especially suitable for contacting electronic units such as printed circuit boards (PCBs) with medium quantities (series testing) and a large number of versions. The test fixtures are designed as an interchangeable kit system, are connected to an existing test system and are operated with exchangeable kits that are specially designed for the electronic unit to be tested.

They boast the following features:

- Interchangeable kit system

- High contact force of up to 2,500 N

- Increased ease of use, without significant clamping forces

- Energy-saving opening mechanism

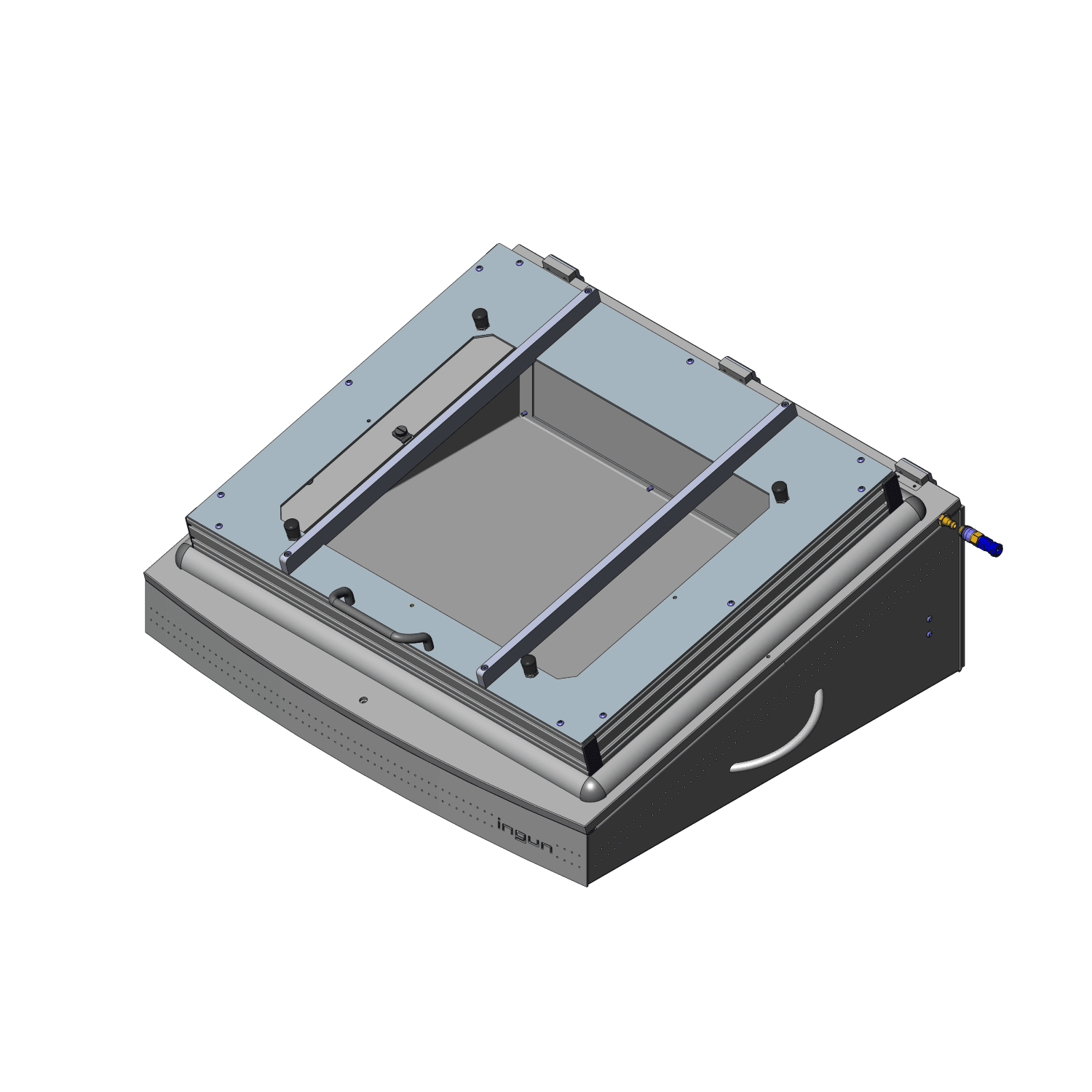

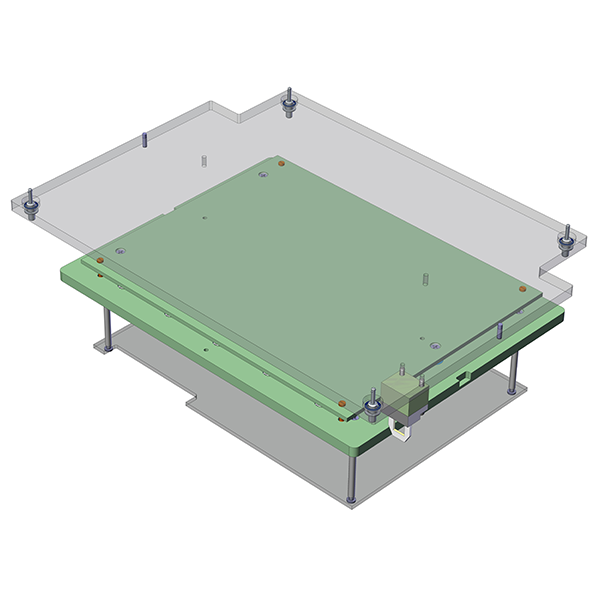

- Basic unit including stiffener bars and circumferential finger guard

- Individualised configuration of internal interface specific to application

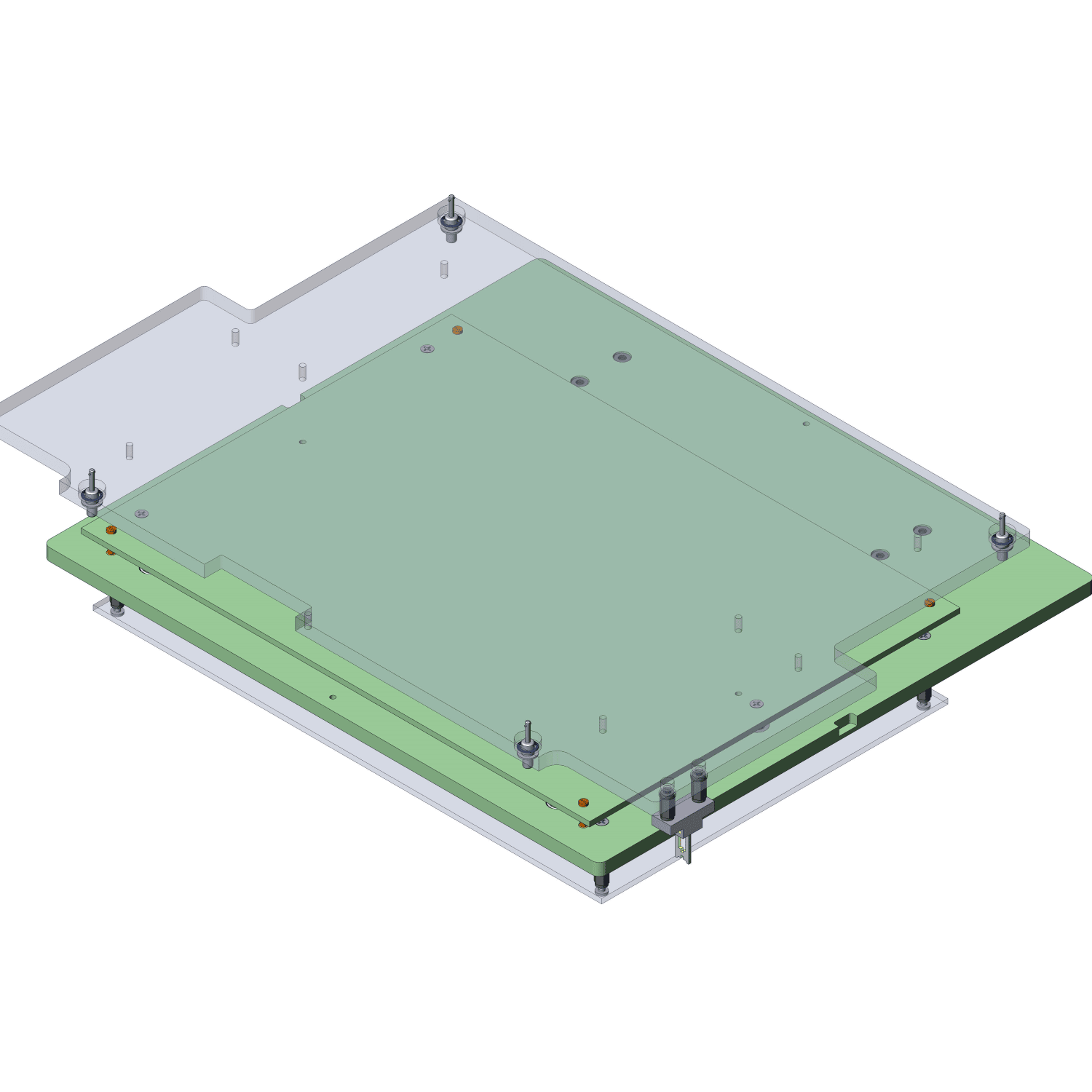

- Exchangeable kits available as standard and ESD versions, tool-free, and can be used without readjustment

- Service life: 1,000,000 load cycles (under laboratory conditions)

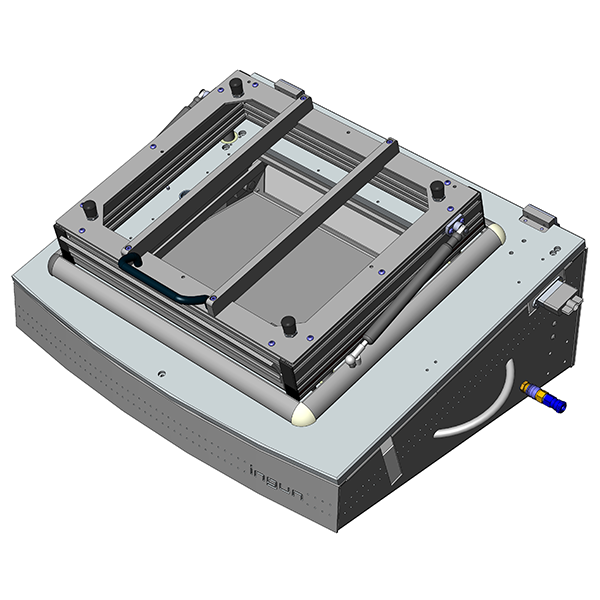

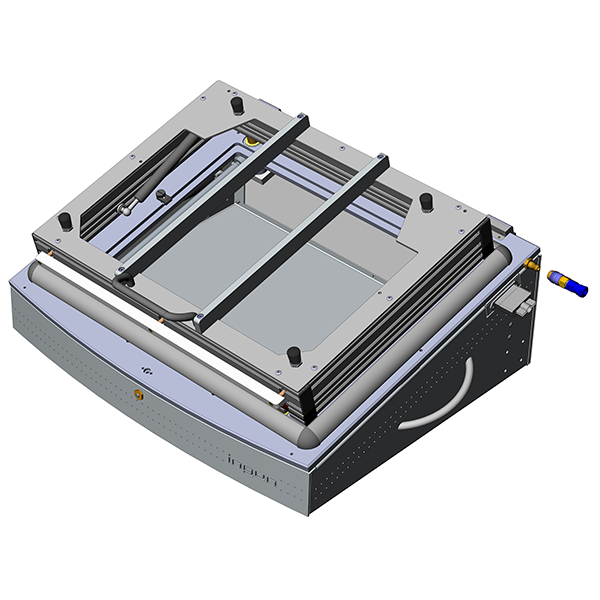

Test fixtures available with either gear drive or cam disc

As standard, the test fixtures are equipped with safety switches for detecting whether the pressure frame is closed, and if stiffener bars and the circumferential finger guard are correctly positioned. The benefit of compressed air results in increased ease of use, without significant clamping forces for high contact forces.

Pneumatic test fixtures are available in two versions: the PAZ xxx series is pneumatically operated using gear wheel drive and the PA xxxx series are pneumatically operated using a cam disc. Both series are available as interchangeable test fixtures and are operated with an exchangeable kit that can be installed with little effort, and no need for tools or readjustment. The pressure frame plate, which can only be loosened and replaced with an open pressure frame unit, is held in place using four quick-release fasteners.