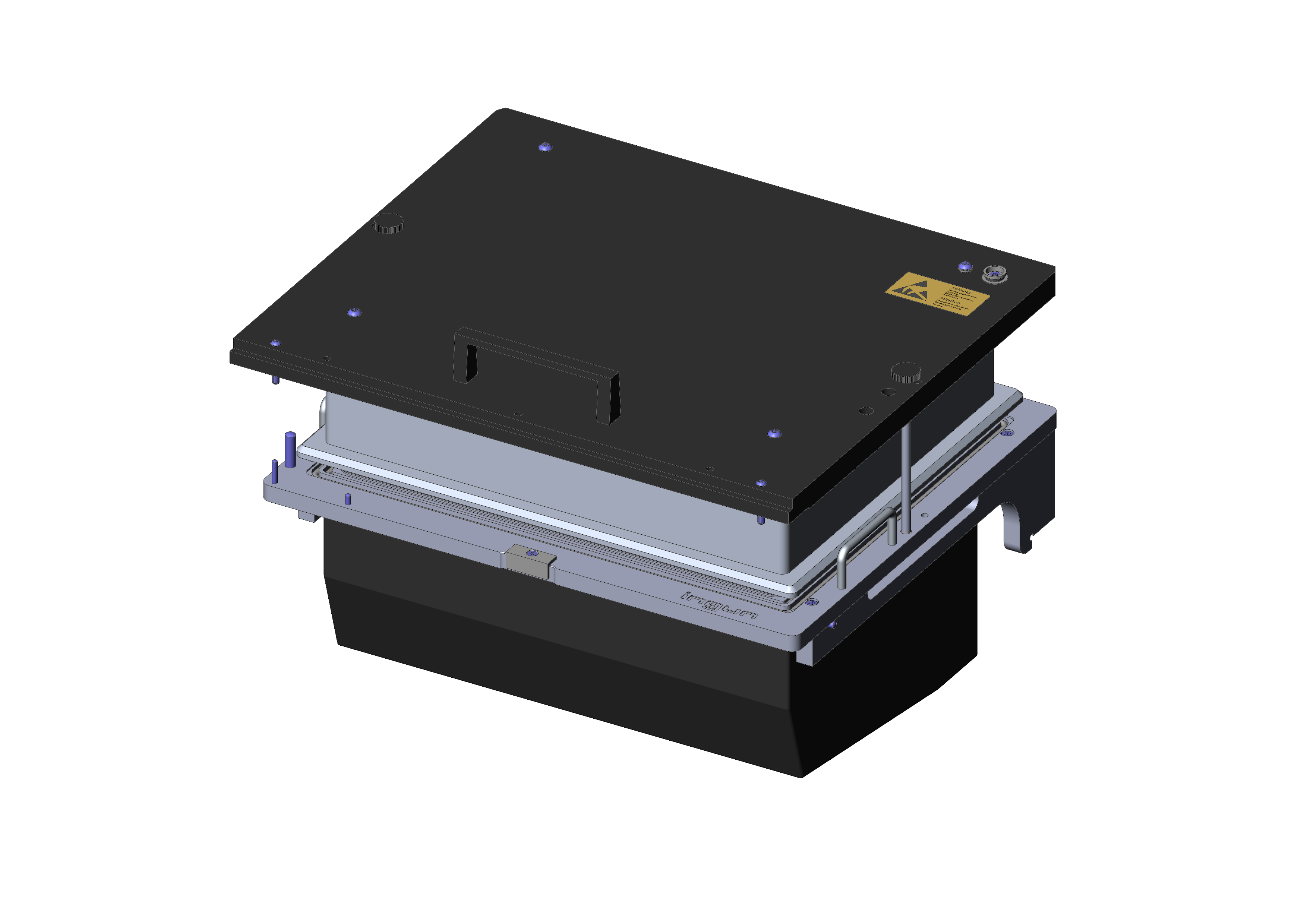

Interchangeable kits (WS) are suitable for contacting high-volume electronic units such as printed circuit boards (PCBs) (mass testing) and a small number of versions. They are installed in an existing inline test system and can be used for side-sided, double-sided, or dual-stage contacting to perform the combined ICT/FCT test.

The boast the following features:

- Robust design

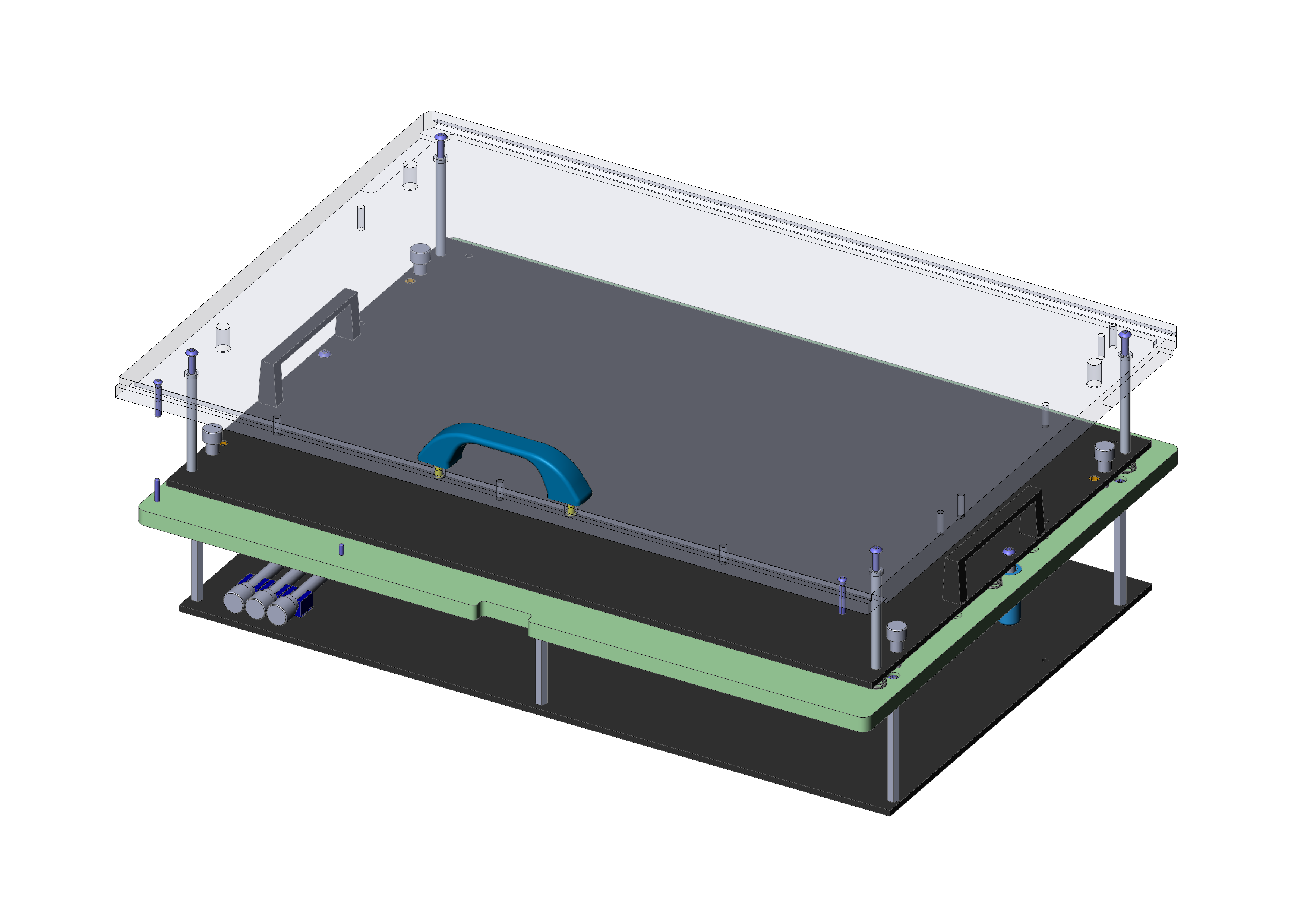

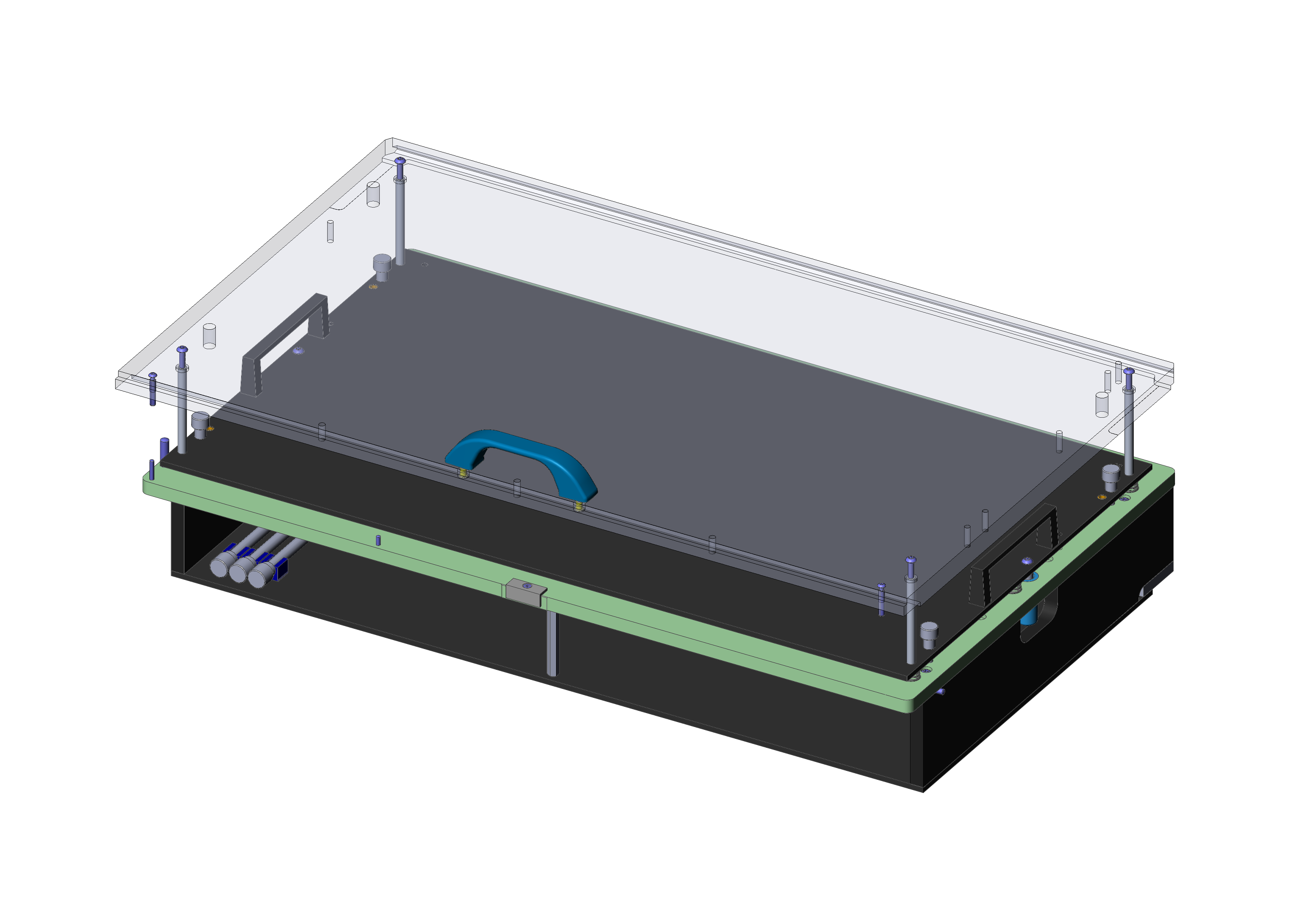

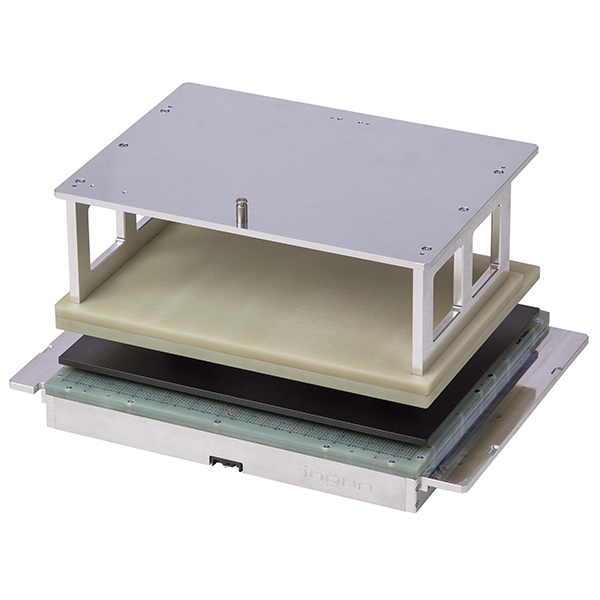

- Modular design with interchangeable kit bottom part (WSU) and interchangeable kit top part (WSO)

- Bend-resistant probe plate made of FR4

- Can be used for single-sided, single / dual-stage or double-sided, single-stage contacting

- Service life: > 2,000,000 load cycles (under laboratory conditions)

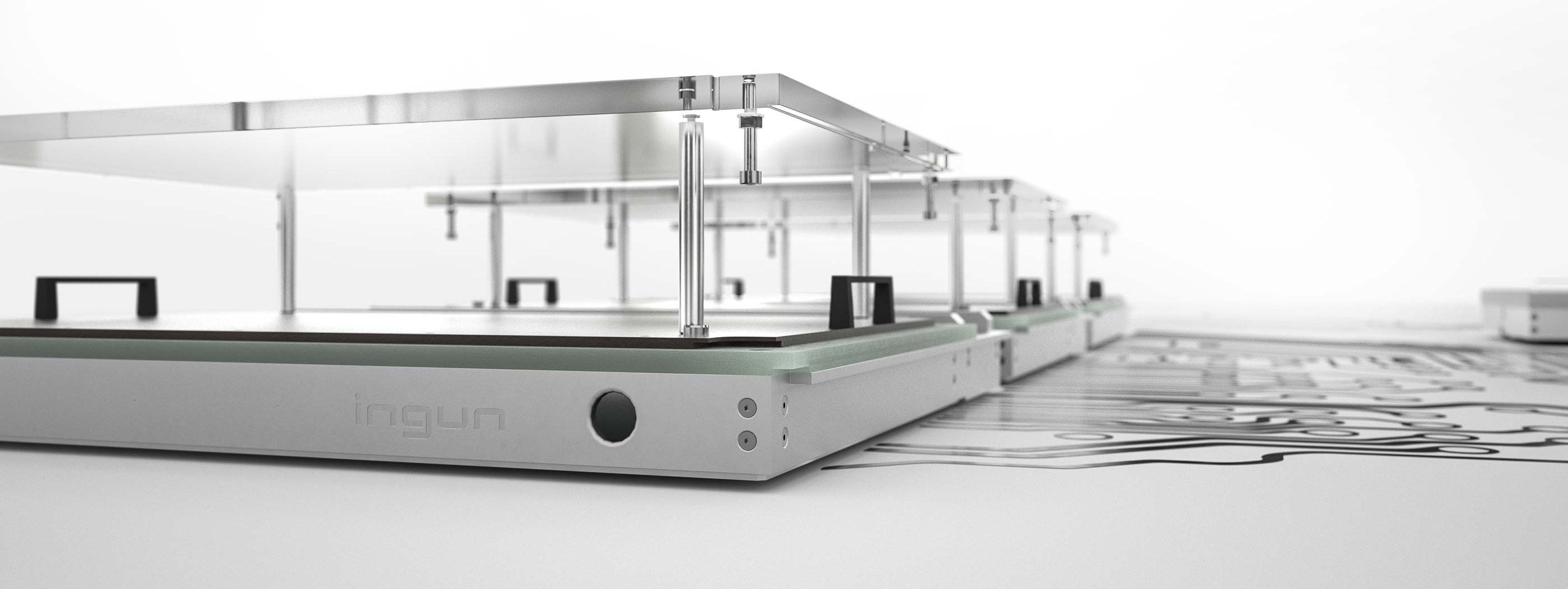

Reliable, consistent contacting in the production line

Interchangeable kits (WS) are modular in design. They consist of an interchangeable kit bottom part (WSU) and an interchangeable kit top part (WSO). They can be mounted quickly and easily in a few simple steps, and boast an impressive robust design for reliable, consistent contacting in inline test systems.

Unlike standard test fixtures, interchangeable kits are not fully functional test fixtures in their own right. They do not have their own lifting mechanism, so they cannot generate their own contacting stroke. The contacting stroke is generated by the inline test system in which the interchangeable kit is used. Inline test systems are primarily part of a fully automatic production line featuring the various processes necessary for printed circuit board (PCB) production. The electrical test (ICT/ FCT) for checking the finished PCBs is carried out in the inline test system.