BATTERY/CELLS

Current state of development

So-called solid-state batteries (SSBs) have been regarded as a potential milestone in battery technology for years. Consequently, they are the subject of intensive research worldwide - particularly in the automotive industry and its suppliers, which will hopefully lead to progress in the driving range of electric cars. Compared to currently prevailing lithium-ion (LI) batteries, which are gradually reaching their physical performance limits, SSBs could achieve significantly higher energy densities of over 350 Wh/kg - LI batteries, on the other hand, typically deliver below 300 Wh/kg.

In addition, solid-state batteries potentially offer a greater degree of safety – they don’t leak and are less susceptible to thermal runaway - as well as a longer service life due to less degradation. In practice, however, there are still some hurdles to overcome in terms of ion conductivity, material compatibility and stability as well as the industrialisation of production - and therefore costs per charging cycle. It remains to be seen to what extent solid-state batteries can prevail over the well-established yet still underutilised LI technology.

Find the perfect material combination

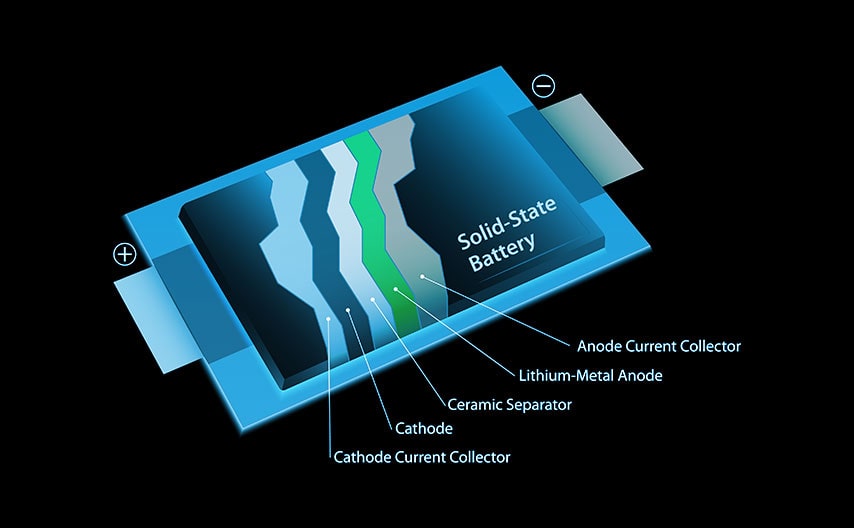

SSBs differ from conventional batteries as they use a solid electrolyte instead of a liquid or gel-like electrolyte (an electrically conductive substance). There are various options for solid electrolytes, each of which has specific advantages and disadvantages. The following types are particularly promising:

- Polymer electrolytes: Are already used in electric buses, are relatively inexpensive, but offer low ionic conductivity at room temperature. Therefore, they should ideally be used at higher operating temperatures.

- Sulphide electrolytes: Offer superb conductivity, but lower electrochemical stability. Challenges exist in terms of industrialisation and costs. Market entry expected between 2025 and 2030.

- Oxide electrolytes: Offer excellent electrochemical stability with moderate conductivity but are more difficult to process. They work well in combination with other electrolytes. Market entry also expected between 2025 and 2030.

Solid-state batteries sometimes require different components and change the entire structure of the battery. Lithium or silicon anodes are used instead of graphite anodes. It always depends on the overall concept of anode, cathode, separator and electrolyte(s). Countless materials and material combinations are currently being researched to find the most promising concept that can also be best realised. Some manufacturers have already presented SSB cells in pouch format and are gradually announcing larger production capacities.

Are hybrid batteries the next development step?

Solid-state batteries do not represent a disruptive step in battery technology, but an evolutionary one. Research in recent years has shown that the key may not be pure solid-state batteries (all-solid-state batteries - ASSB), but hybrid concepts that operate with various electrolytes on the anode and cathode side - in this case anolyte and catholyte. Both solid-liquid and solid-solid combinations are promising, for example sulphide and oxide electrolytes.

It remains to be seen whether it will be possible to overcome the technical complexity of SSBs and produce them industrially on a large scale at a reasonable cost. Ultimately, solid-state batteries will have to assert themselves on the market against the established LI technology. If they do, nothing will stand in the way of their use in stationary applications such as smartphones and electrical appliances.