INDUSTRY 4.0

Industry 4.0: The seamless networking of production

The fourth industrial revolution, known as Industry 4.0, is fundamentally changing the manufacturing industry. The use of modern technologies such as the Industrial Internet of Things (IIoT) and artificial intelligence (AI) is making production more flexible, efficient, and intelligent. At the centre of this development is the industrial Ethernet - the indispensable data highway for networked production environments.

Industry 4.0 describes the complete integration of digital technologies into production. In the past, machines operated largely in isolation and carried out repeatable processes. Today, these systems are closely networked, collect data in real time, and enable seamless communication between man, machine, and system. This connectivity forms the basis for smart factories, which are characterised by high efficiency, predictive maintenance, and optimised processes.

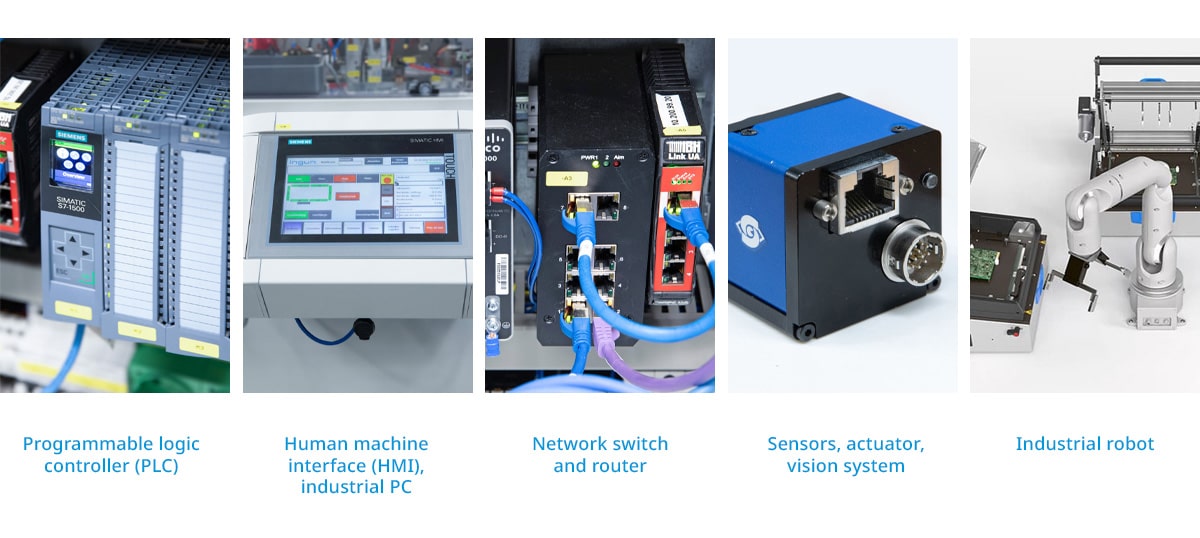

Core elements of Industry 4.0, such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), network switches, sensors and industrial robots, must be perfectly harmonised. Production processes can only be designed to be flexible and scalable if these components work together smoothly.

Example applications for networked components in Industry 4.0

Industrial Ethernet: The backbone of smart factories

Industrial Ethernet is a specially customised version of the conventional Ethernet that meets the specialised requirements of industrial environments. With high reliability, low latency times, and robust protocols, it enables the fast, reliable transmission of large amounts of data - even under challenging conditions such as high temperatures, vibrations, or electromagnetic interference.

In the smart factory, industrial Ethernet ensures that all systems communicate reliably with each other and are perfectly synchronised. This networking is crucial for the success of Industry 4.0 applications that rely on real-time information and precise control.

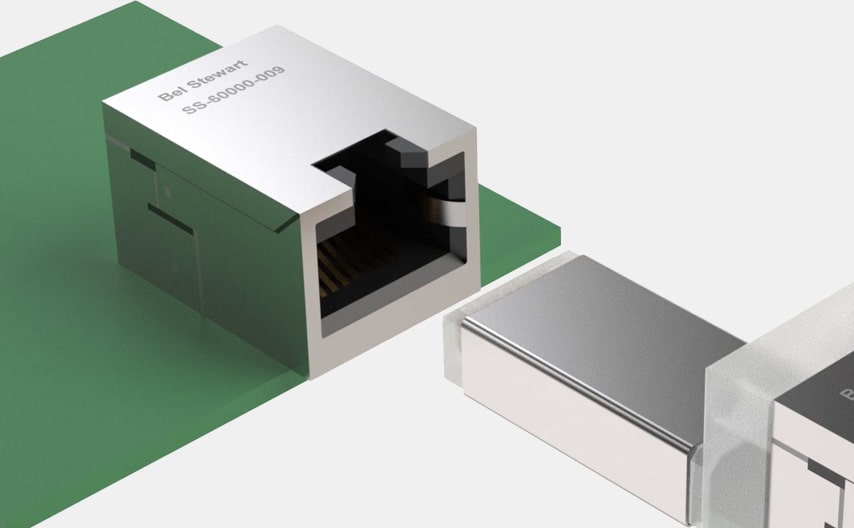

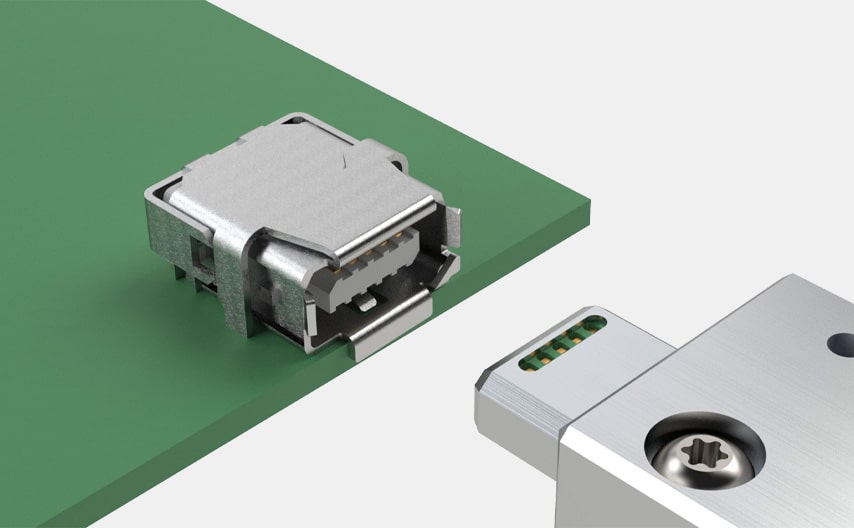

Connectivity: Connectors in Industrial Ethernet

Connectivity plays a central role for industrial Ethernet. This is where specialised connectors such as RJ45 and ix Industrial™ come into play. While the RJ45 connector is a proven solution for Ethernet-based networks, the ix Industrial™ connector offers a more compact, robust alternative that has been specially developed for industrial applications. It enables reliable connections that can withstand even the most demanding conditions and thus secure the future of networked production.

Connectors such as the RJ45 and ix Industrial™ provide the connectivity required for networking industrial applications

Conclusion: Industrial Ethernet as the engine of Industry 4.0

Industrial Ethernet is the driver for the digitalisation and networking of production in the age of Industry 4.0. It seamlessly networks PLCs, HMIs, network switches, sensors, and robots and enables efficient, flexible and safe production. Robust connectors such as RJ45 and ix Industrial™ ensure the reliable connectivity that is essential for the operation of smart factories.