E-MOBILITY

The development towards autonomous driving is in full swing. The prerequisite for this is powerful, reliable data transmission in vehicles. Differential connectors play an important role here - these are used to ensure the multitude of vehicle systems can be connected efficiently. The reliability of these connectors is guaranteed using new testing technology from INGUN, such as the radio-frequency test probe HFS-802 and the brand-new KS-802 mounting frame for six HF-802 H-MTD probes.

A modern car can contain up to 100 electronic control units (ECUs): from simple control programs to embedded platforms to complex, multifunctional real-time operating systems. In particular for safety applications such as driver assistance systems (ADAS), which are the basis for autonomous driving, reliable high-speed data connectors are increasingly needed. Currently, level 3 of 5 has already been achieved as partially automated driving is now possible. On the journey to fully automated driving, the number and complexity of the systems in the vehicle - also for networking with the environment (V2X) through 5G (in future 6G) - will continue to increase.

Differential connector systems form the basis for this. In each case, two cables are routed in parallel to ensure interference and deviations in the transmission can be analytically compensated for. Differences cancel each other out, meaning digital data can be transmitted in high quality and at increasingly higher data rates - for example, for cameras, infotainment, automotive Ethernet, and many other applications. One of the first differential automotive connector systems, the HSD series from Rosenberger, continues to provide connection of digital signals to the ECUs and has been tested using the HFS-819 test probe series from INGUN for years. However, this generation is gradually being replaced by more modern and more powerful systems.

Suitable test solutions for high performance connectors

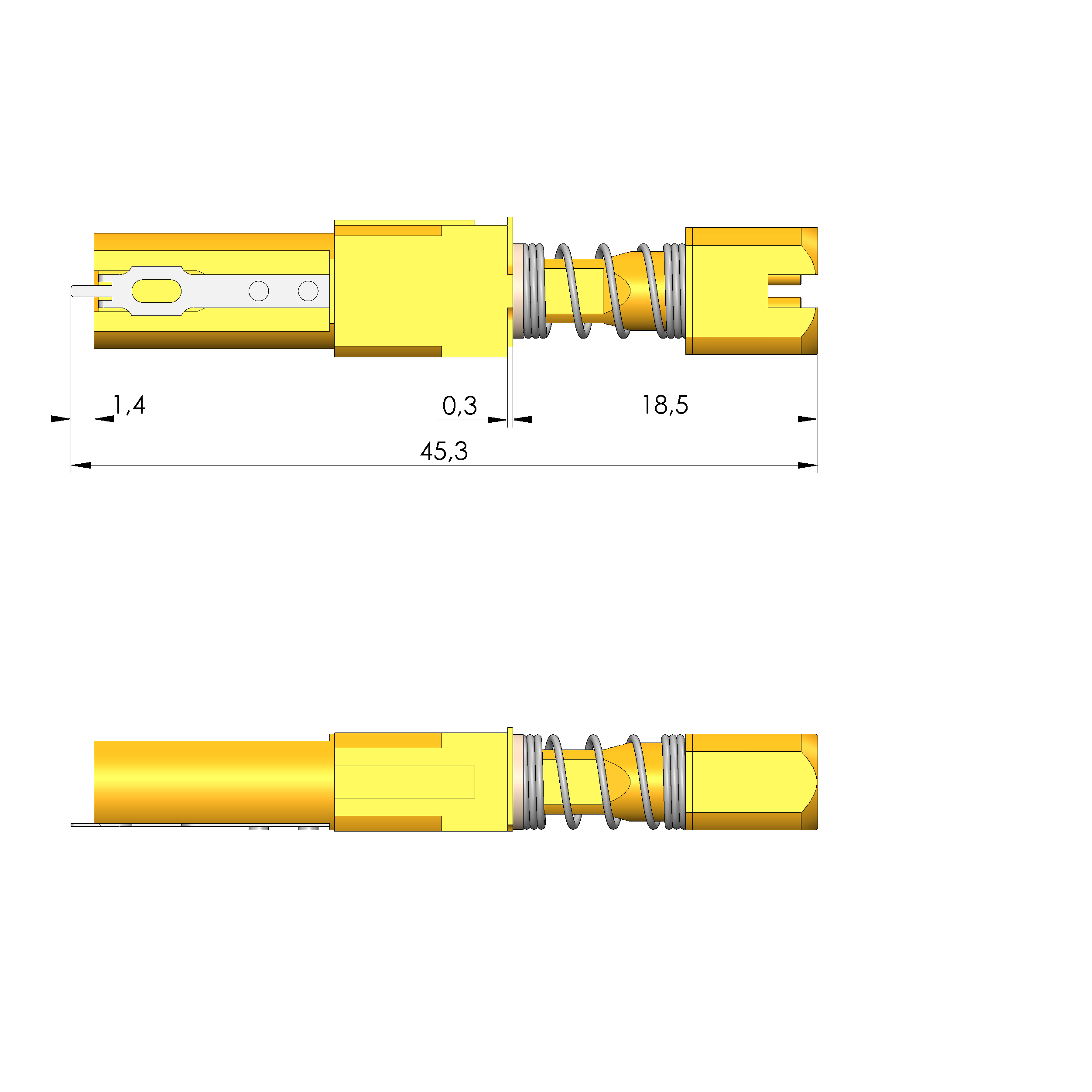

INGUN provides suitable test solutions for advanced connector systems. The radio frequency test probe HFS-802 (available for H-MTD and MATEnet connectors) is as modular as the systems to be tested and provides the required performance in the frequency range up to 20 GHz. In addition to the transmission performance, the focus here is on the long service life due to the low-wear design and the optimised abrasion behaviour.

Powerful, robust, and variable networking in the smallest of spaces

Differential connector systems must meet high requirements in terms of durability, safety, transmission speed as well as modularity and flexibility in the application:

- Durability and safety

Primary and secondary locking; high cable retention force; mis-mating and damage to test probes is avoided - Speed

Radio frequency data transmission with up to 20 GHz and data rates of up to 56 Gbit/s - Modularity and flexibility

Savings in installation space of up to 80 percent; support of automotive Ethernet and numerous SERDES protocols; variety of cable versions, e.g., shielded twisted pair (STP) and unshielded twisted pair (UTP)

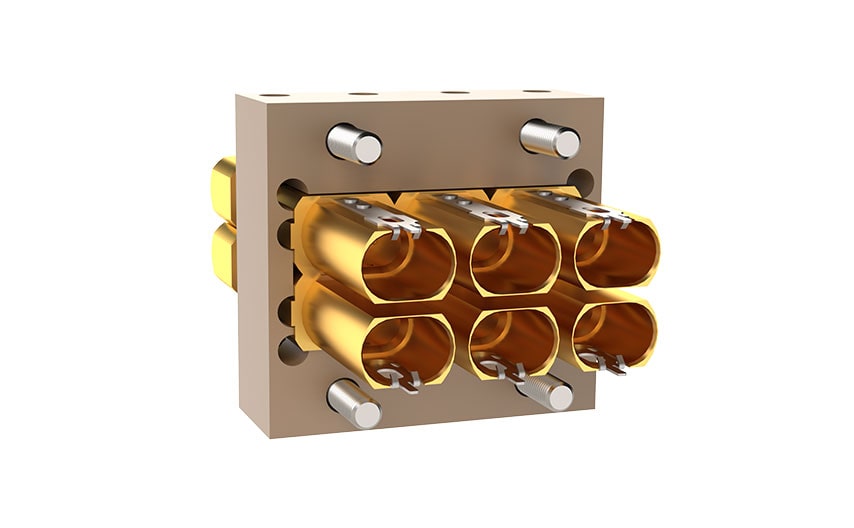

H-MTD test probe with 6-socket frame

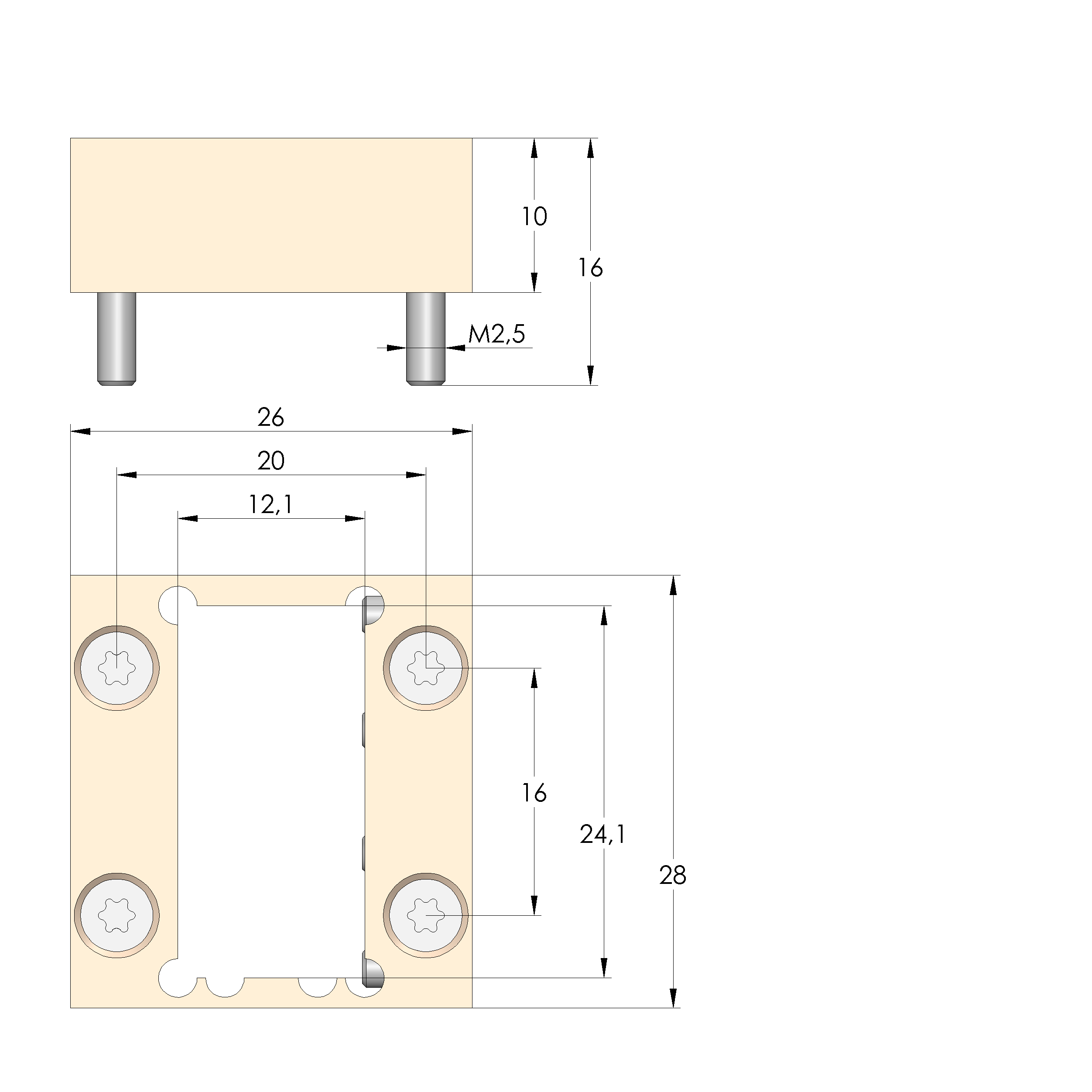

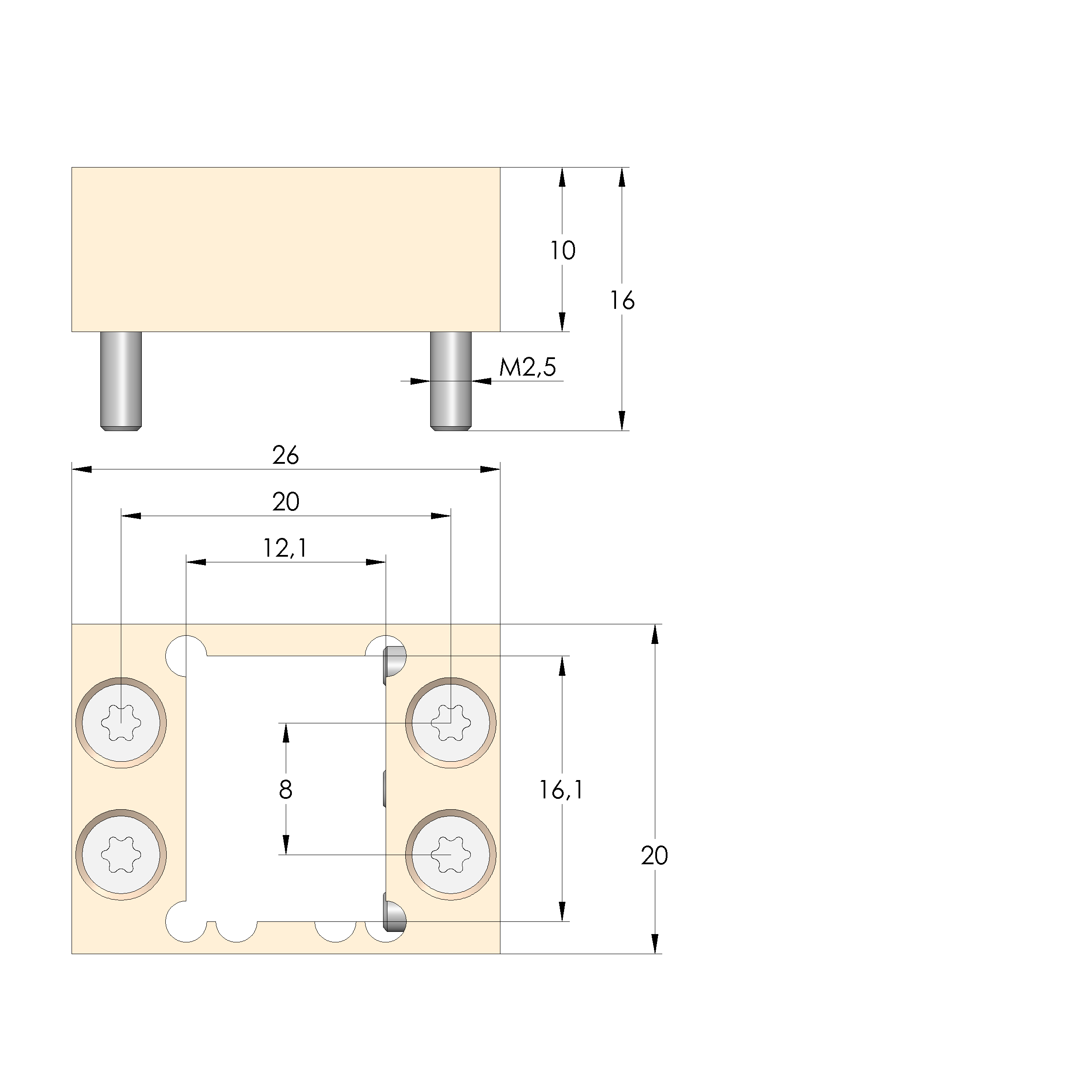

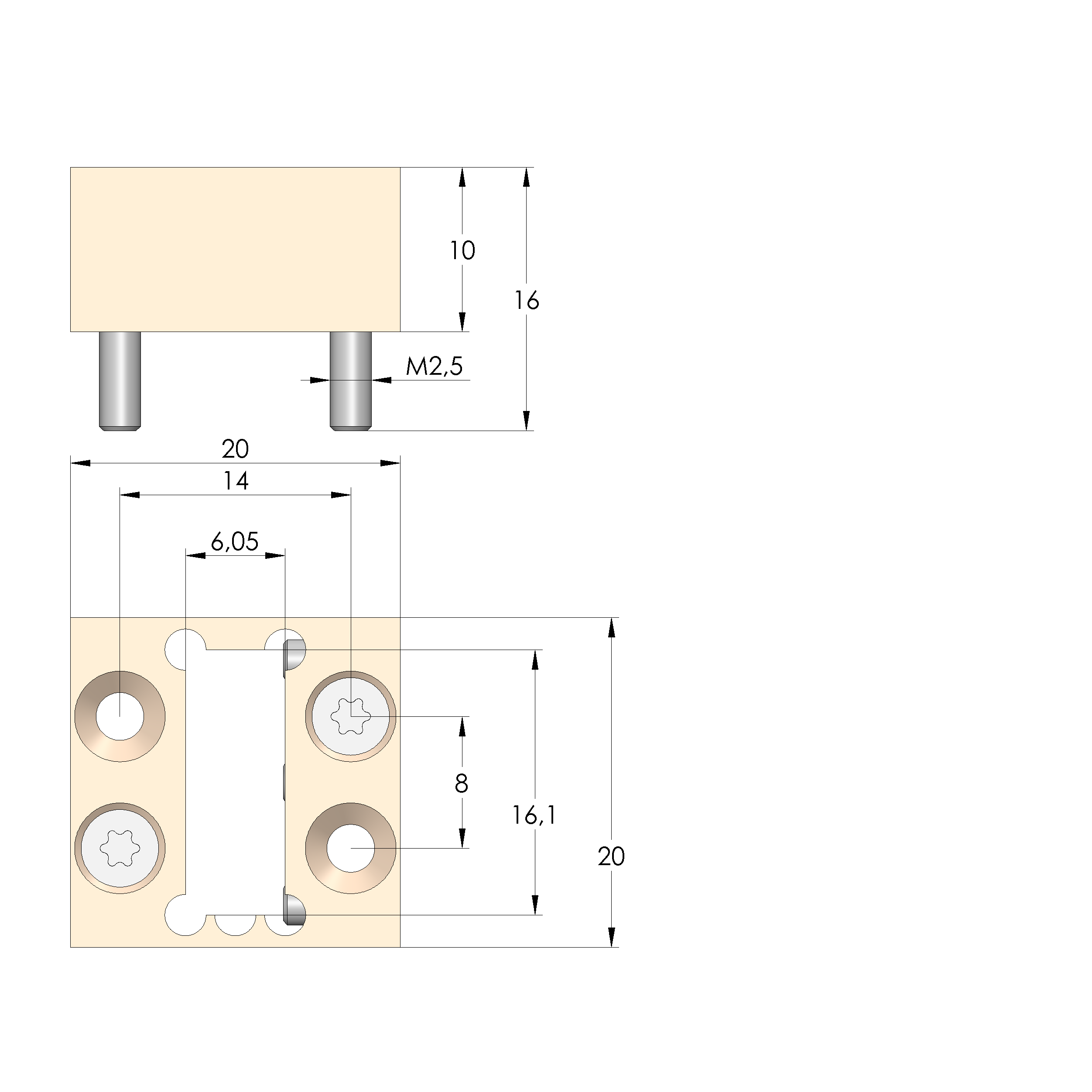

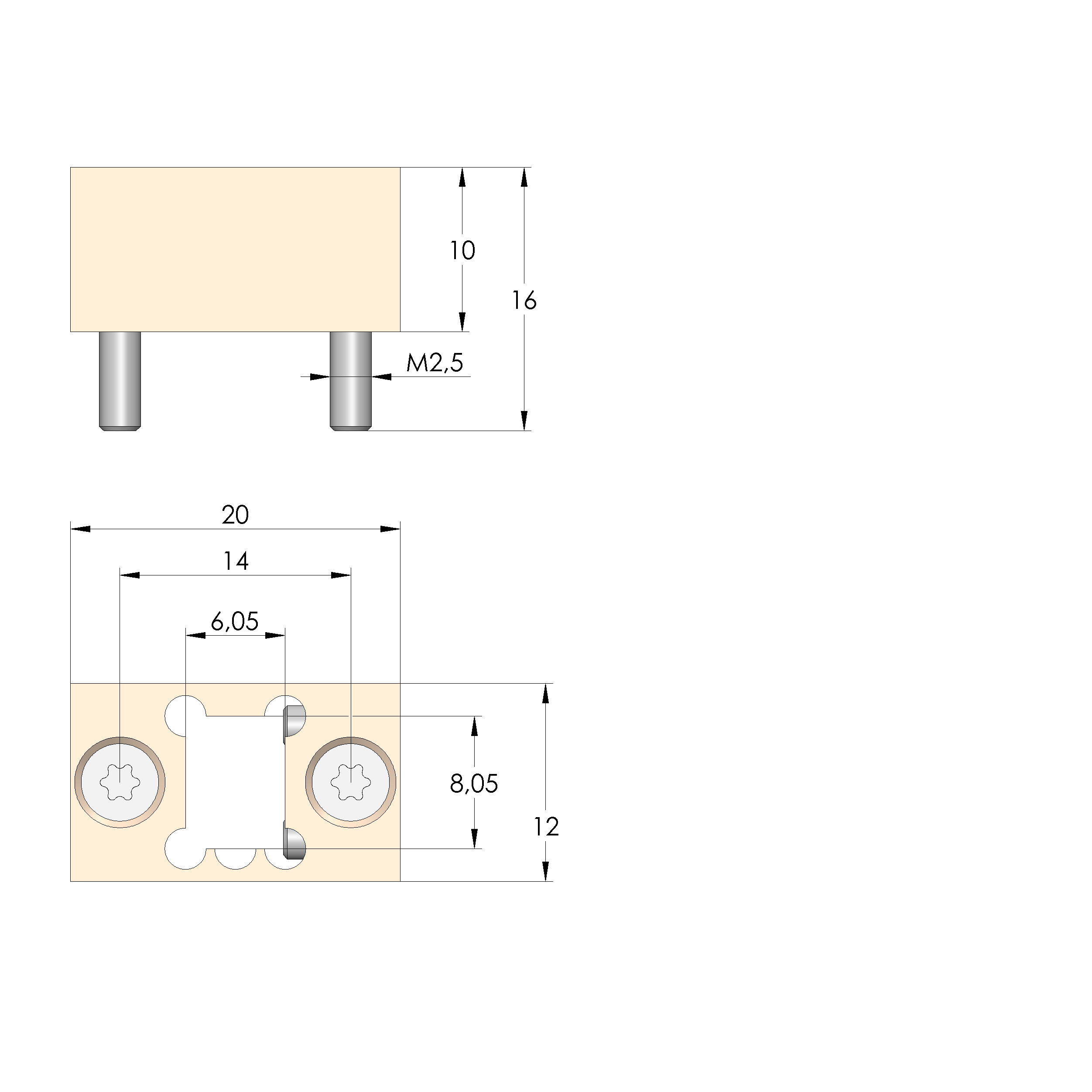

With the HFS-802 H-MTD series and the new KS-802 HMTD 6-socket frame, INGUN is ideally positioned to fulfil the requirements of the automotive industry.

Thanks to the mounting frames, it is possible to contact H-MTD connectors with several contact parts in a single housing. For customers who customise fixtures, there is no need to install their own contact blocks, as only the frame needs to be installed in the fixture. Thanks to the screw connection of our HFS-802 H-MTD, the contact solutions are already positioned in the correct grid for the connector to be contacted. The probes themselves have a floating mechanism. This efficient solution saves time and resources while ensuring a precise, reliable connection. With our high-quality mounting frames, you can optimise the contacting process and significantly increase the efficiency of your workflows.

Discover the advantages of the modularity and efficiency of this innovative testing solution

- Optional accessory for installing 6x HFS-802 HMTD

- Precise, low-wear contacting of test probes

- Reliable data transmission

- Expansion of the existing range, which includes KS-802HMTD-1, KS-802HMTD-2, KS-802HMTD-4

Easy installation of test probes into the mounting frame

- Test probes enable tolerance compensation thanks to floating mechanism

- Simple installation of assembled mounting frame in the test fixture

- Connection to the test system via H-MTD cable

- Individual test probes can be easily replaced