PRODUCTS

It is well known that the market leader is the one who gets the most out of his cell technology. This results in an advantageous position that distinguishes them thanks to relevant technical features such as capacity and performance data. The core know-how of the battery therefore lies in ageing, forming, and use management.

With the help of INGUN products, various battery types can be contacted in the individual production and process steps such as charge/discharge, formation, room/high temperature ripening, -impedance measurement (AC-IR/DC-IR), open circuit voltage (OCV) . Module, pack, as well as end-of-line contacting applications are carried out via various connector types.

The range of test and charging currents is up to 1,200 amperes under environmental and climatic influences of high and low temperatures. With the help of our diverse product portfolio, our customers can effortlessly carry out robust contacting at cell, module, or pack level.

Battery test cycle

Battery formation

The formation of the battery is the elementary, decisive process that defines the performance characteristics of the cell. Processes lasting several hours/days serve to build up and form the inner cell structure. This requires a reliable, continuous connection in combination with low contact resistances to avoid power losses and dissipation of heat. From an energy point of view, the forming process is burdened by high energy consumption. Characterised by transition resistances, it is important to reduce these.

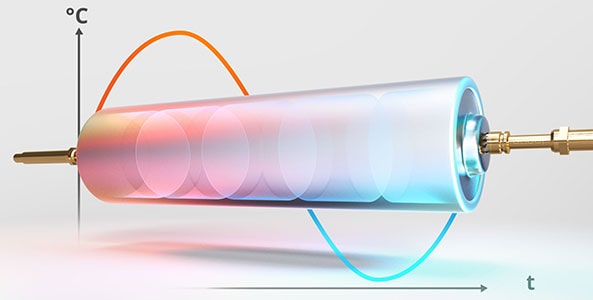

Maturation

Maturation describes the temporal process of the internal structuring of the cell. This takes place under both room and high temperatures and is a process adjacent to formation. The aggravated climatic conditions in the high temperature range, additive to the contact resistances, require the development of the perfect test pin. For the cyclic measurement of the OCV (open circuit voltage) the products of INGUN are used.

Cell test to end-of-line test

The determining cell tests take place at the cell level and are used to grade the battery by means of insulation measurement, OCV, SOC, ACIR/DCIR and cyclic charging and discharging. In the cell manufacturing sector, the individual cells are contacted using the appropriate pin design. In the further manufacturing process, the current requirements increase due to the cumulative cell to module interconnection. In module assembly, the main connector of the cell connector is contacted via a central interface consisting of bundled individual cells. The finished product consequently consists of several modules and is interconnected as a complete system. The final test in the final assembly step takes place via the HV connectors as an end-of-line test. The individual currents amount to the total current here and represent the essential challenge with the corresponding current density.

Quality products for the most reliable process

Developing a suitable product means understanding the requirements of the process and the application. Our portfolio goes beyond state-of-the-art and includes products for future technologies in use worldwide.

In addition to the measuring contact, the portfolio includes four-wire and temperature measurements at the tab/terminal. This provides users with direct monitoring of the contact point over time.

Due to ever-increasing requirements in the battery sector and within the manufacturing processes, we are continuously developing our portfolio. Future trends, increased power densities, and growing requirements of cell-to-pack technology demand new product dimensions. For our customers, we at INGUN are ready to fulfil the market requirements in an agile development process.