Half a century of experience

For over 50 years, we have been setting standards in developing high-precision testing and contacting components across all industries.

Whether in the automotive industry, medical technology, or renewable energies - INGUN stands for quality, innovation, and reliability.

40+

locations

worldwide

65+

countries

with INGUN products

10,000+

loyal

customers

E-mobility on the rise

Few industries are evolving as rapidly as electric mobility. As the leading supplier in the automotive industry, we understand the challenges our customers face, particularly in battery cell contacting:

- Poor energy efficiency due to intense heat generation

- High production costs due to long processing times

- Short service life of components due to demanding operating conditions

Our in-house battery unit anticipates these issues and continuously adapts our proven contacting solutions to meet our customers' needs.

Discover EG Extensa's Universal Test Fixture for Cylindric Batteries

EG Extensa specialises in producing test systems and fixtures for electronic devices and batteries. To meet customer demand for improved accuracy and efficiency in battery testing, the company developed a universal test fixture for cylindrical batteries. The main challenge faced during this project was ensuring a stable and low connection resistance while connecting high current to the Device Under Test.

Together with the experts from INGUN, EG Extensa developed an even more precise and efficient test solution, now benefiting from high-quality test probes:

- High current support: Capable of handling currents up to 100 A with a delta +≤ 20 °C.

- Optimized for energy efficiency: Engineered to reduce contact resistance, ensuring significant energy savings and outstanding signal stability for durable, reliable electrical contacts, e.g. by penetrating the oxide layers of aluminium tabs.

- Precision voltage measurement: Available with a sense contact feature for accurate voltage readings.

Thanks to the expertise and consulting of INGUN EG Extensa has further developed its battery testing equipment and expanded its market presence.

What is different?

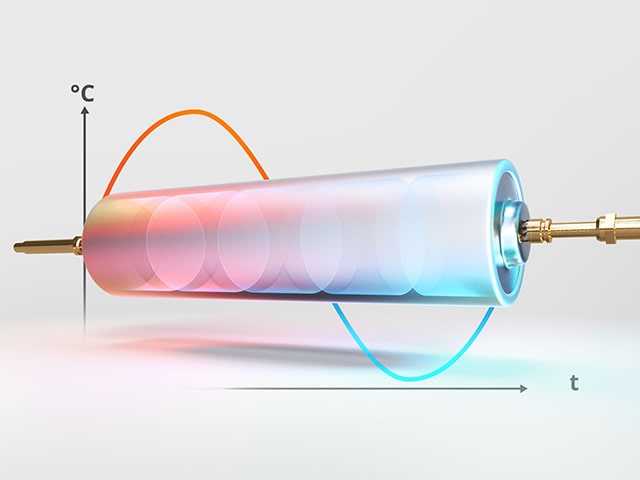

Our BCP and BCC series are specifically designed to reduce the contact resistance and keep the temperature increase constantly below 20 Kelvin. How do we do this?

By equipping our products for battery cell contacting with these unique features:

CLEVERCOAT®:

Our high-quality palladium coating prevents the test probes from tarnishing.

Non-moving cable:

Direct mounting in busbars eliminates the need for cable installations.

Tip style:

The unique shape of the plunger tip allows our test probes to push through aluminium oxide layers.

Cooling/non-cooling:

Our test probes can be cooled both actively and passively during the formation process.

Why INGUN?

Our specialised products for battery cell contacting will save you energy, shorten your formation and testing times, and guarantee the maximum durability possible.

Over 10,000 customers from various industries already rely on INGUN – now it is your turn.