Receptacle KS-113 30 M2-R-S Item KS-11330M2-R-S

Receptacle KS-113 30 M2-R-S Item KS-11330M2-R-S

Please log in to show the price

Login

The prices listed in the scale are displayed rounded, therefore deviation in the total price is possible.

Shipping costs

* The prices are rounded to two decimal places.

Technical data

| Product group : | Receptacles (KS) |

|---|---|

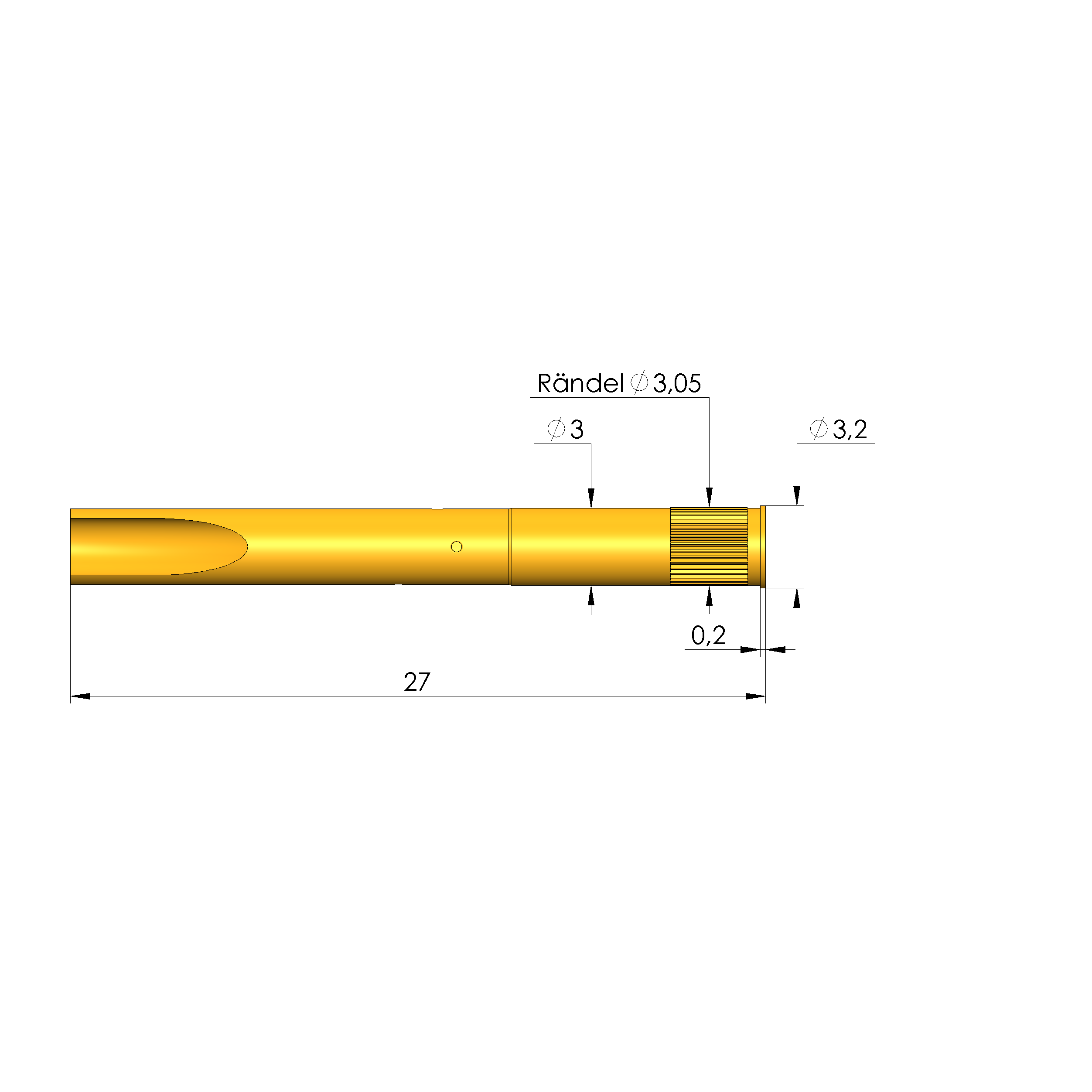

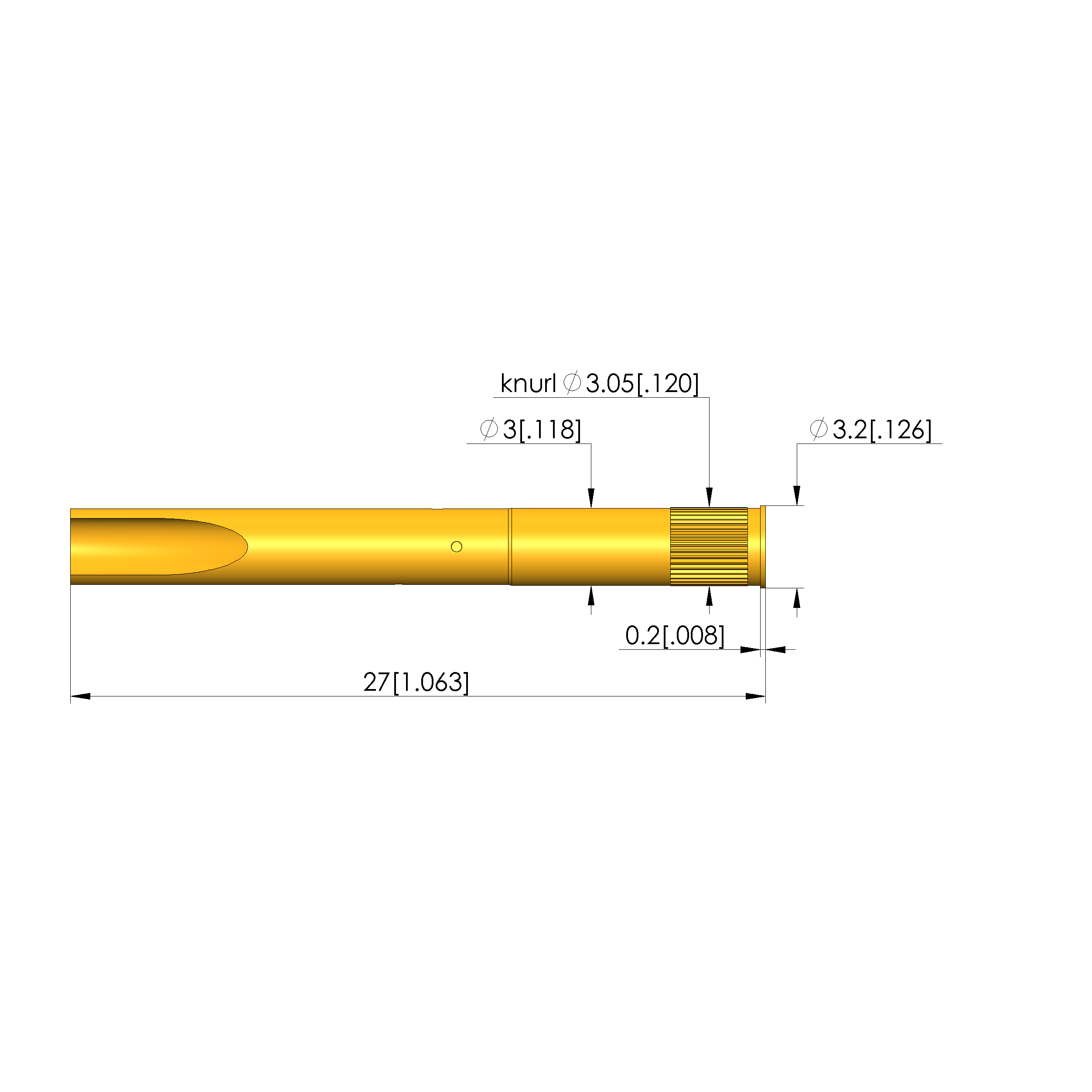

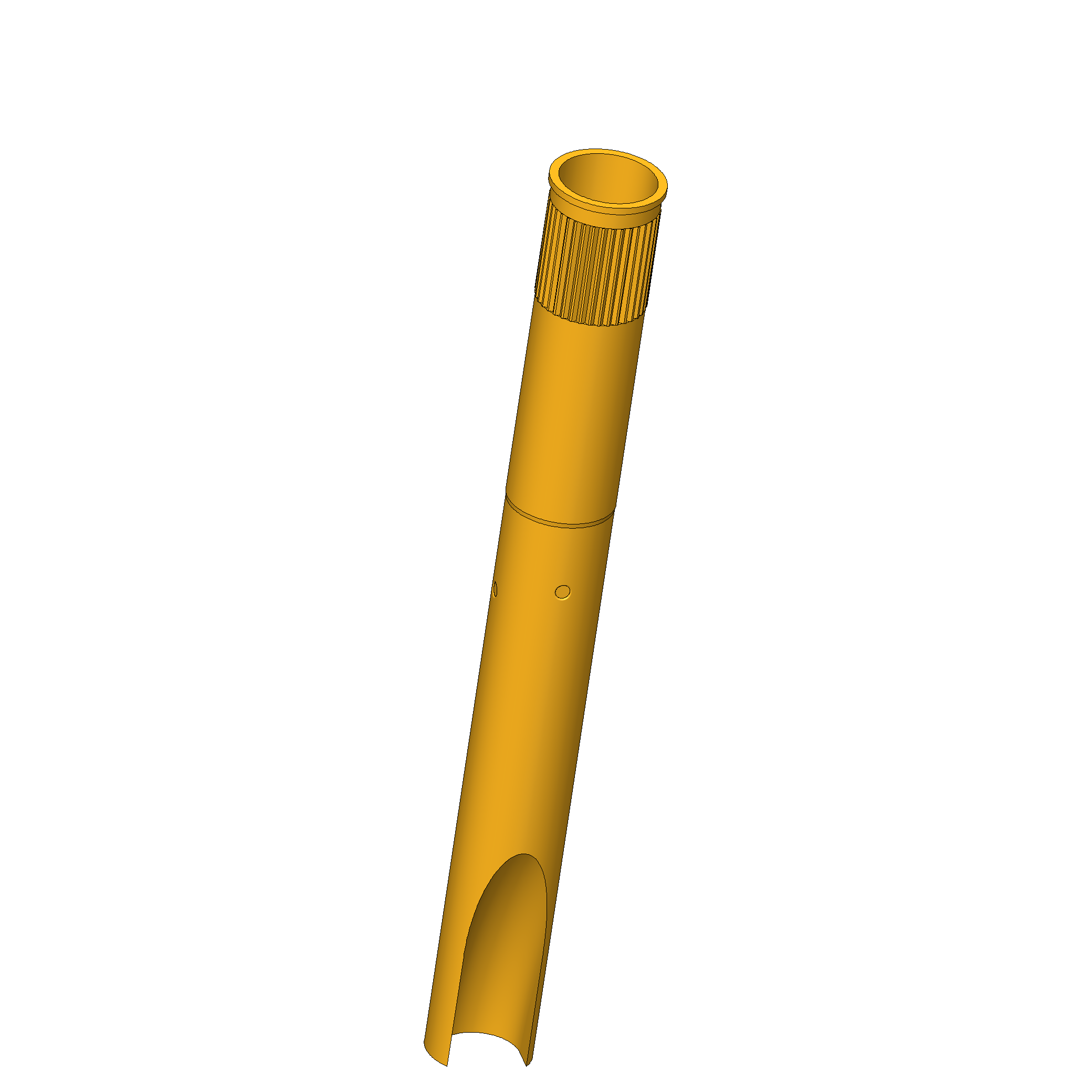

| Series : | KS-113 |

| Sub-series : | KS-113 M screw-in version |

| Type of receptacle connection : | Solder |

| Press ring : | No |

| Surface area : | Gold |

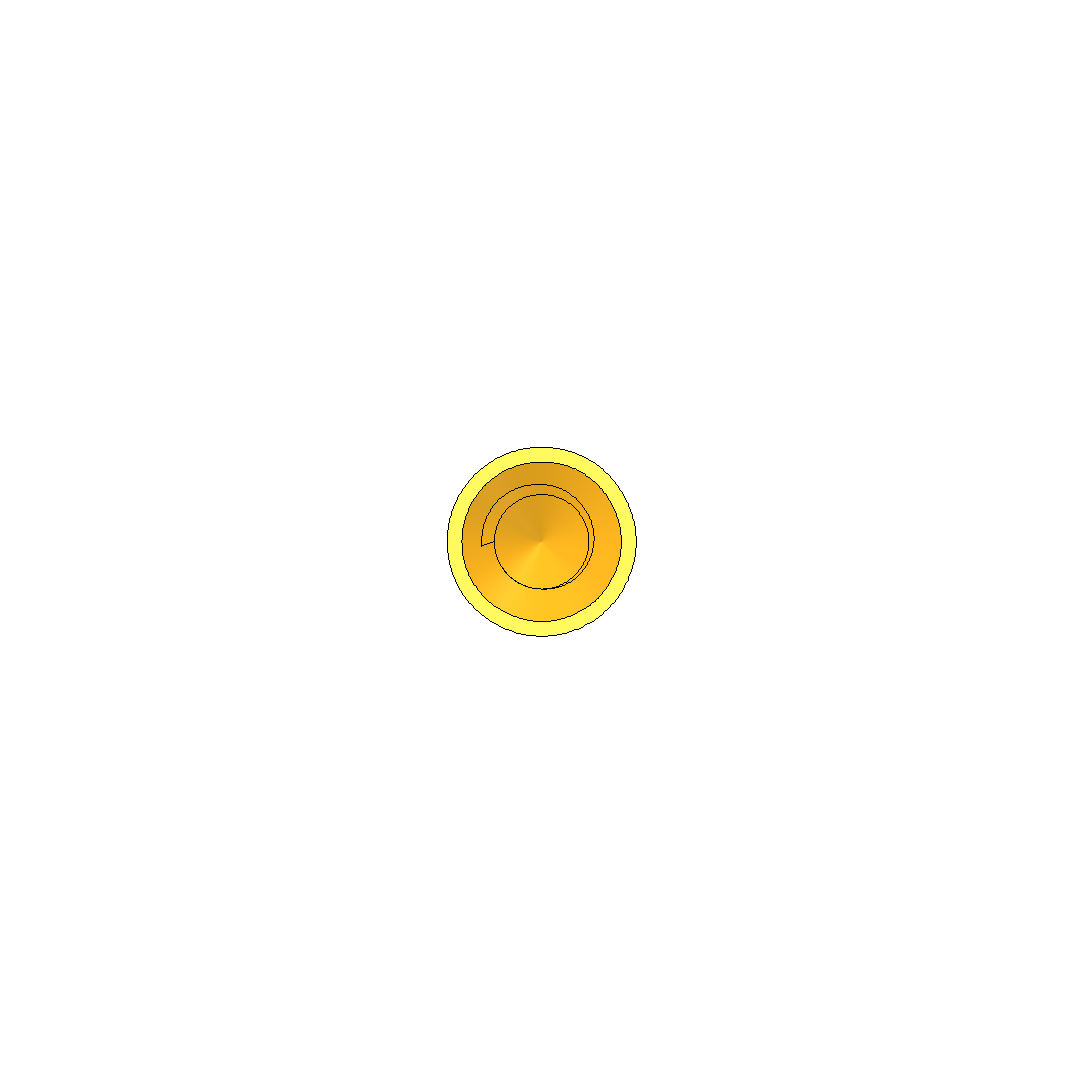

| Collar diameter : | 3.2 mm |

| Collar height : | 0.2 mm |

| Knurl : | Yes |

| Vacuum-tight : | No |

| RoHS-compliant : | RoHS-3;6c |

| Mounting hole in CEM1 : | 3.00 - 3.02 mm |

|---|---|

| Mounting hole in FR4 : | 3.00 - 3.02 mm |

| Total length : | 27 mm |

|---|---|

| Outer diameter : | 3 mm |