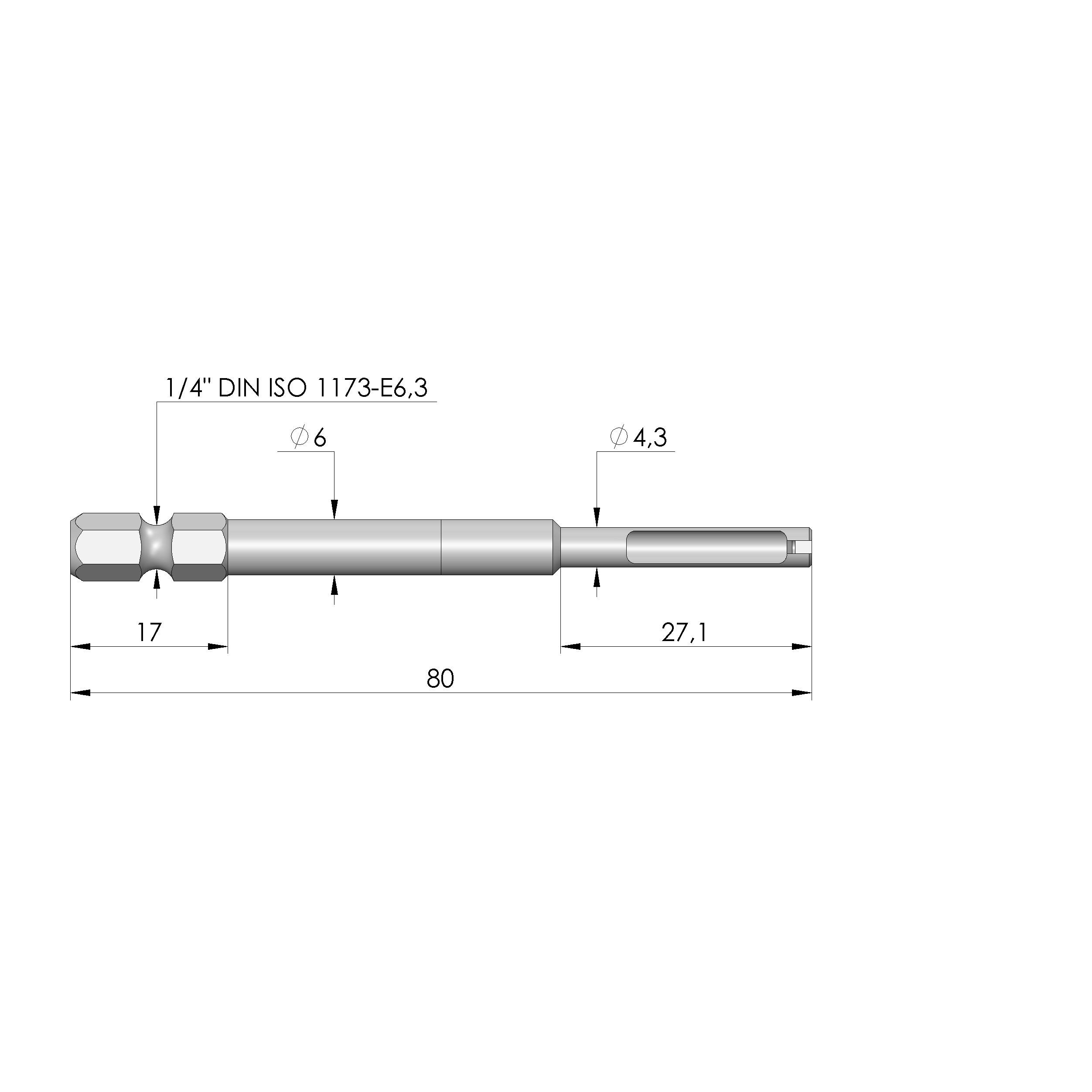

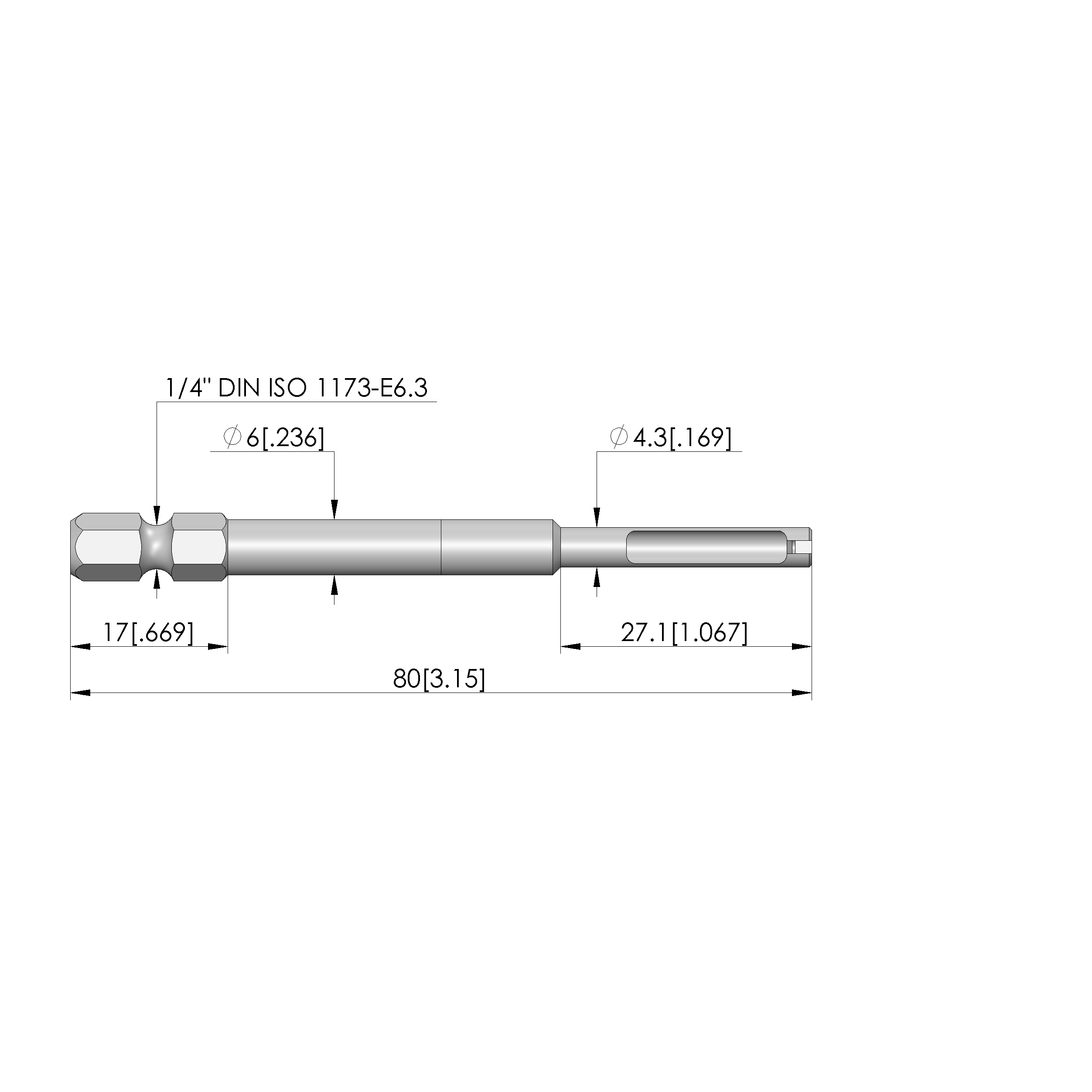

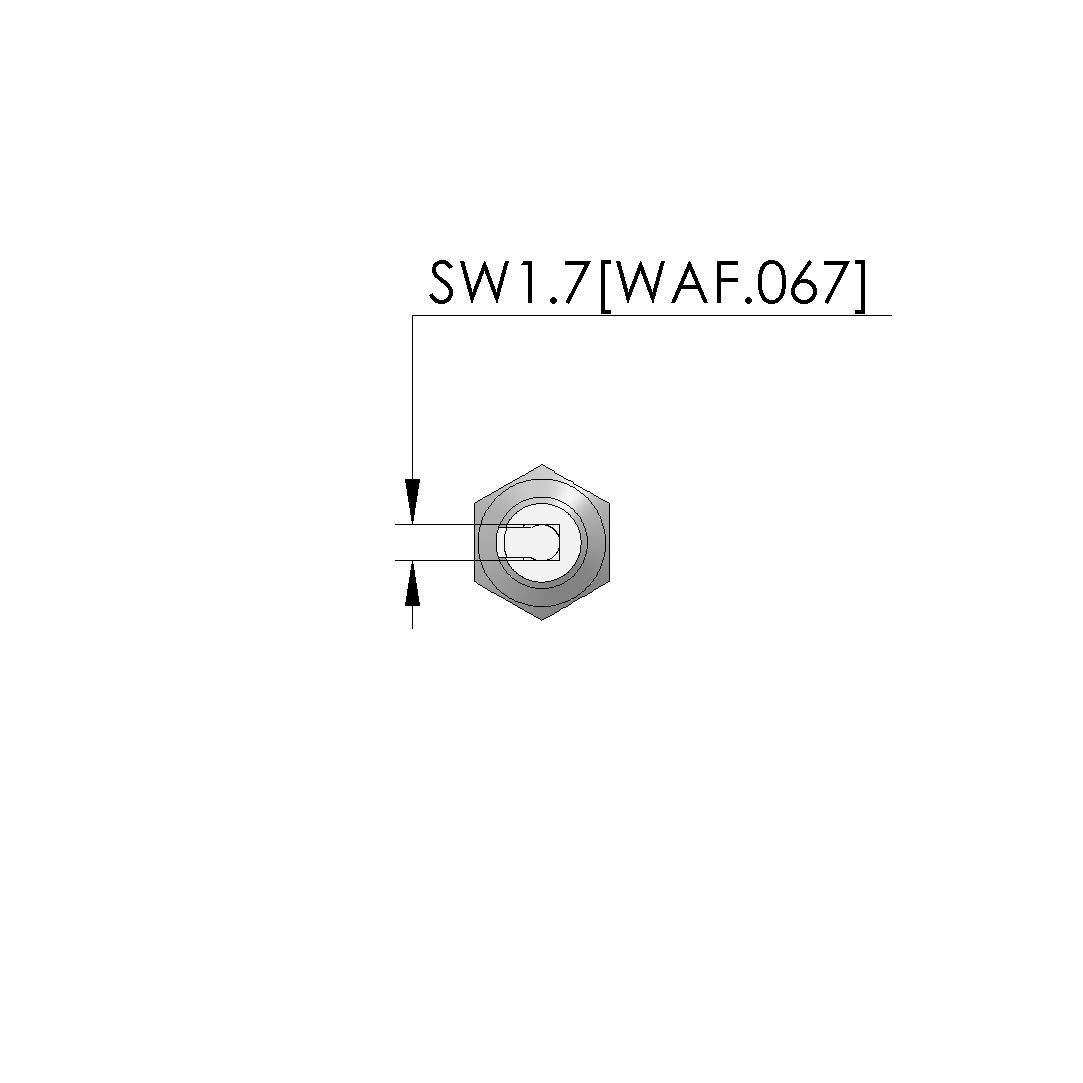

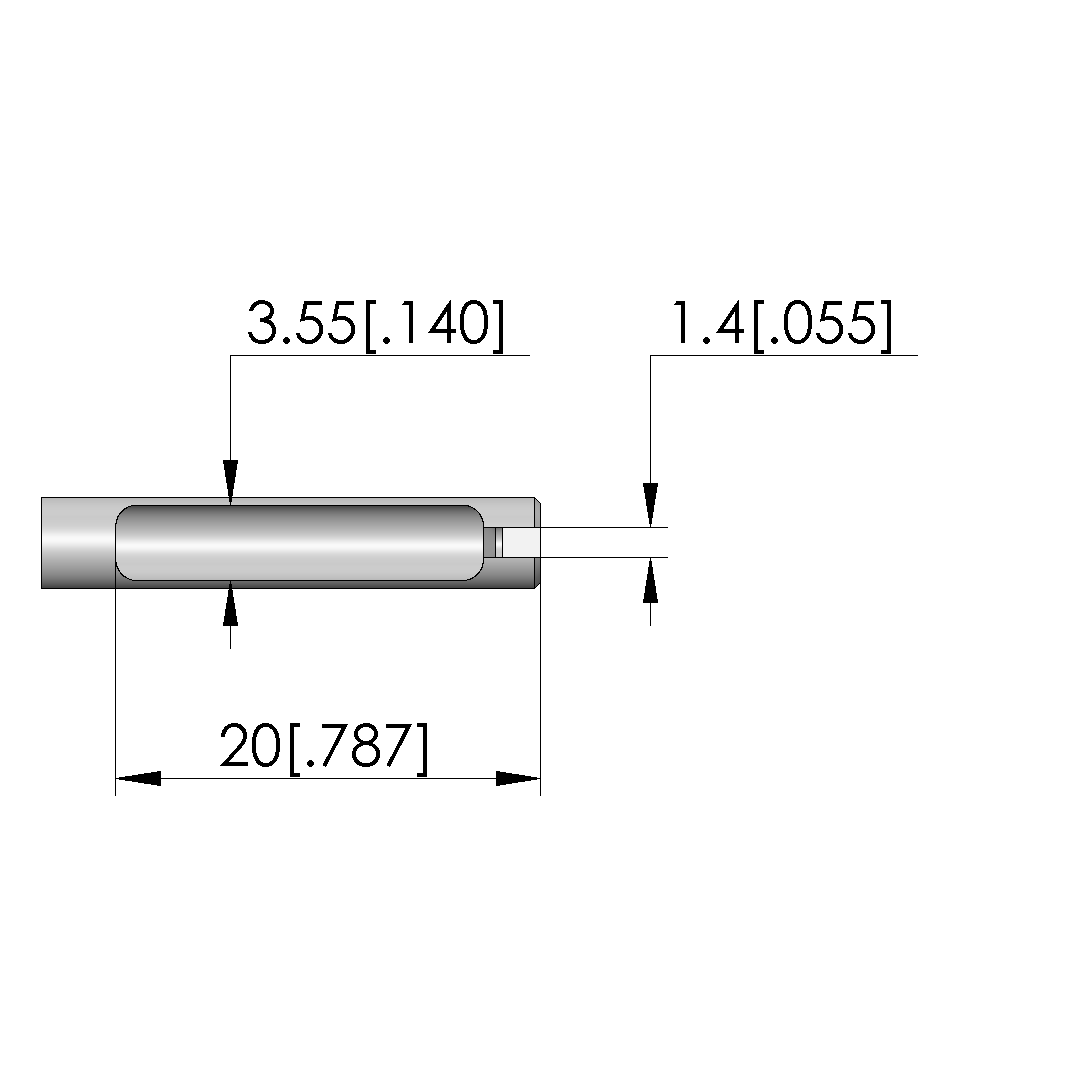

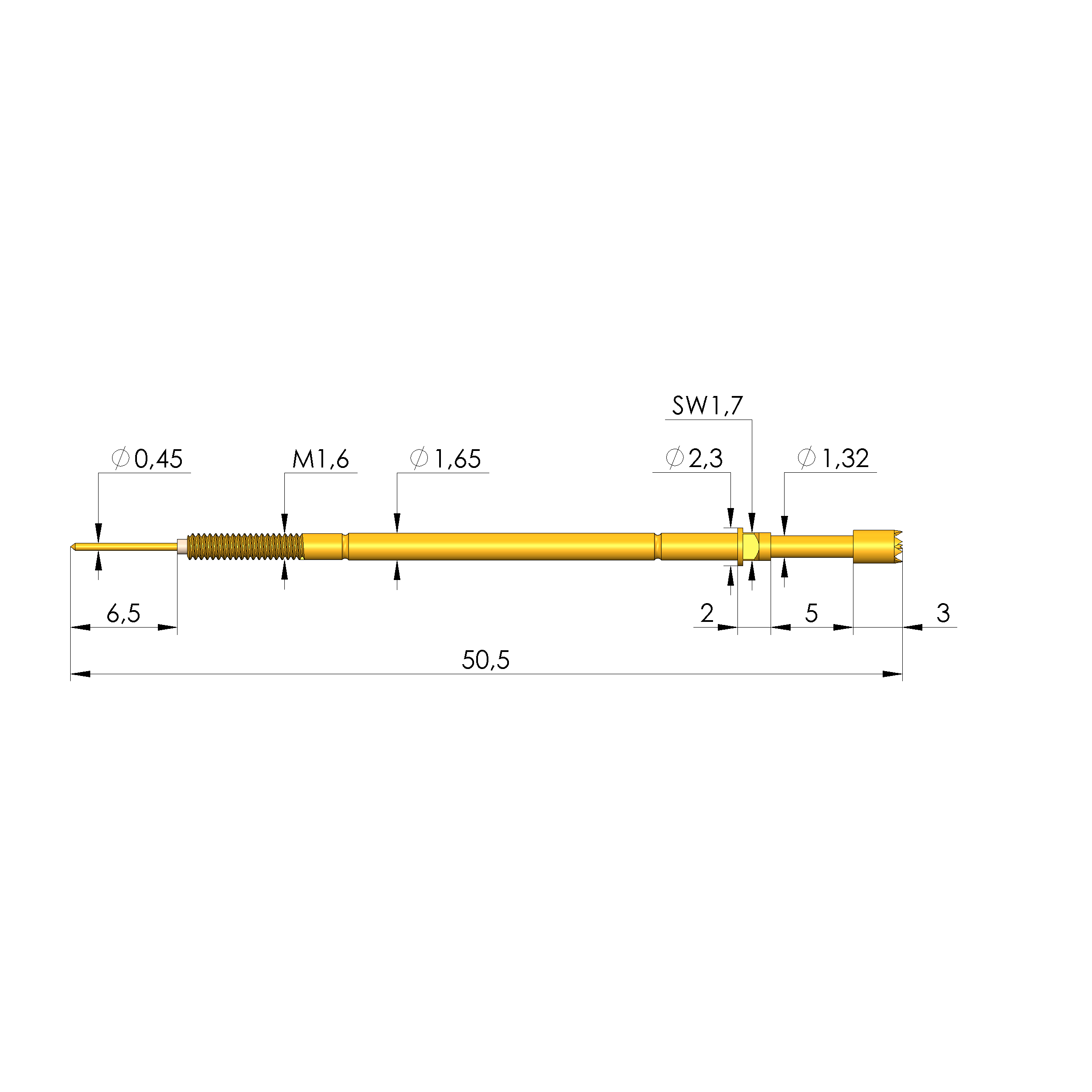

Screw-in tool BIT-GKS-112 M Item BIT-GKS-112M

Screw-in tool BIT-GKS-112 M Item BIT-GKS-112M

Please log in to show the price

Login

The prices listed in the scale are displayed rounded, therefore deviation in the total price is possible.

Shipping costs

* The prices are rounded to two decimal places.

Technical data

| Product group : | Bit inserts (BIT) |

|---|---|

| Compatible test probe(s) / receptacle(s) : | 006 GKS-112, HSS-118, SKS-215, T-112, DPS-215, HFS-409 |

| Series : | BIT-GKS |

| Tool for receptacle (KS) : | No |

| Tool for test probe (GKS) : | Yes |

| Test probe installation type : | Screw-in |

| Max. tip diameter : | 3.5 mm |

| Tool version : | Rigid |

| Screw-in torque : | 3 - 5 cNm |

| RoHS-compliant : | RoHS-3 |